Water-based absorption type electromagnetic shielding coating material and preparation method thereof

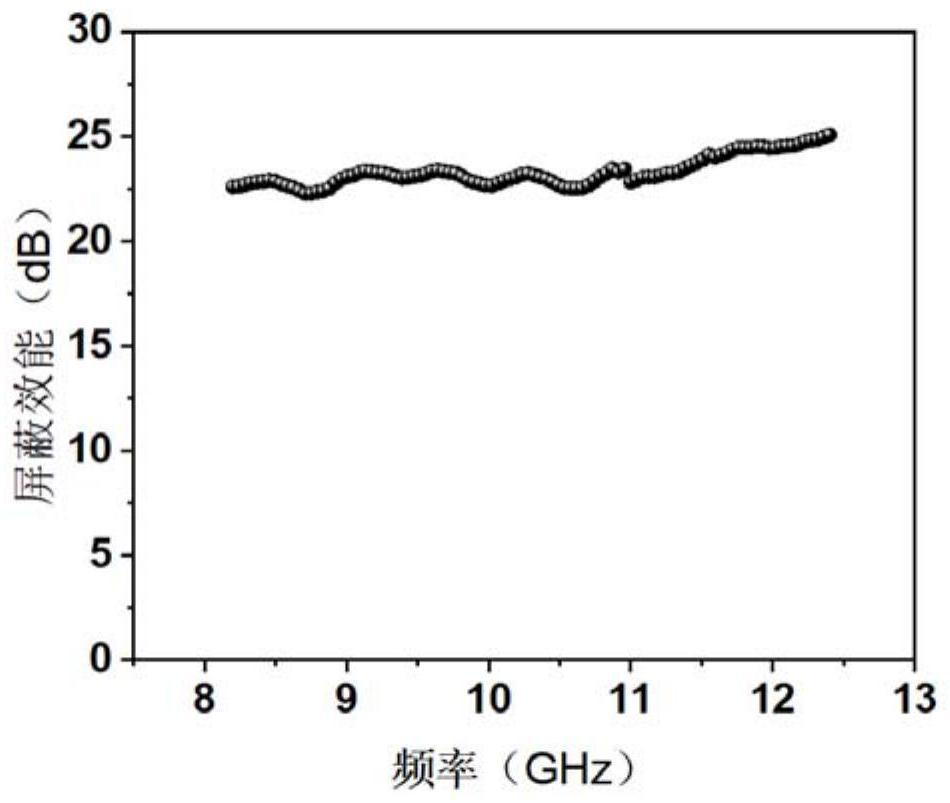

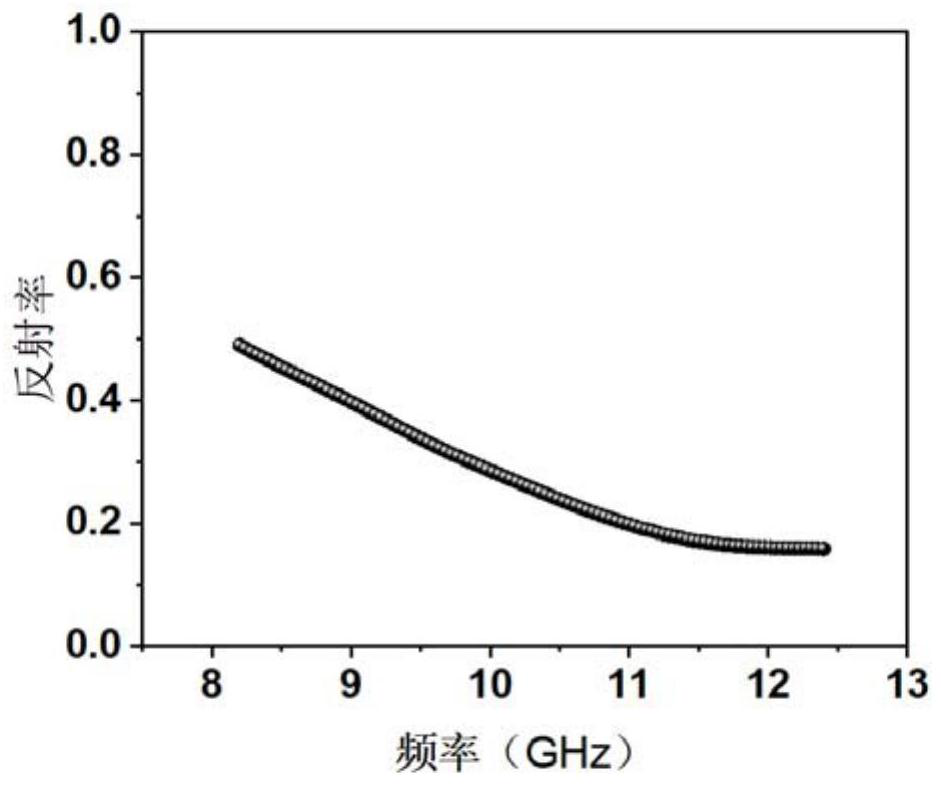

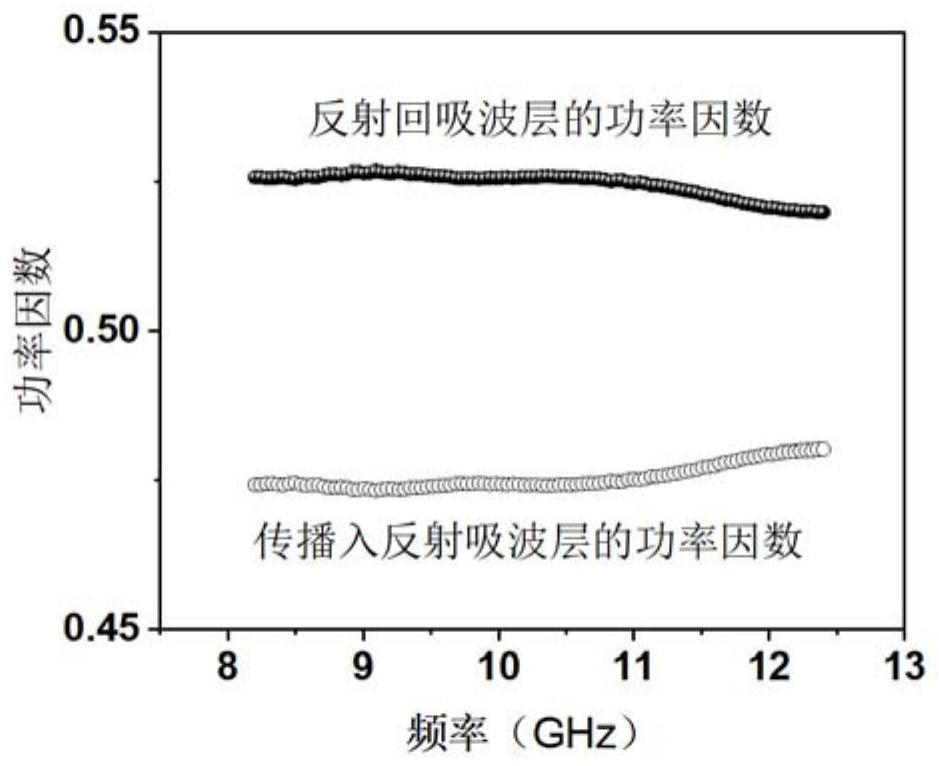

A technology of electromagnetic shielding and coating materials, applied in the direction of radiation-absorbing coatings, coatings, reflection/signal coatings, etc., can solve the problems of narrow absorption bandwidth of composite films, narrow absorption bandwidth of electromagnetic shielding materials, and inability to absorb electromagnetic waves, etc., to achieve Broaden the absorption bandwidth, thin thickness, and improve the effect of impedance matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation method of a water-based electromagnetic shielding coating material. The specific steps are as follows:

[0027] 1) Use the self-polymerization reaction of dopamine hydrochloride to modify graphene under weak alkaline conditions to obtain polydopamine-modified graphene GNS@PDA, blend 10-20wt% GNS@PDA with anionic polyacrylate latex, and coat on solid On the substrate, after drying, a polyacrylate / GNS@PDA composite coating with a thickness of 0.2mm-0.45mm is obtained;

[0028] 2) Treat graphene oxide (GO) in a vacuum oven with a vacuum degree of -1bar at 200°C for 4h to obtain reduced graphene oxide (RGO), and blend 8-20wt% of RGO with anionic polyacrylate latex, Directly coat the polyacrylate / RGO composite latex on the polyacrylate / GNS@PDA composite coating prepared in step (1) to obtain a polyacrylate / RGO coating with a thickness of 1.3mm-2.2mm, after drying A water-based absorbing electromagnetic shielding coating material is obta...

Embodiment 1

[0033] 1) Add 0.5 g of dopamine hydrochloride to 300 mL of Tris buffer and 100 mL of ethanol at room temperature, and use its self-polymerization reaction to modify 1 g of graphene under weak alkaline conditions (pH value=8.5). After 24 hours of reaction, Suction filtration and rinse with water to obtain GNS@PDA. Then take 1g of the above-prepared GNS@PDA and 10.81g of anionic polyacrylate latex Yanbang 141, disperse evenly under the action of ultrasonic waves in a water bath, spray on a square polytetrafluoroethylene substrate with a side length of 12.9cm, and obtain a thickness of 0.2mm after drying The polyacrylate / GNS@PDA coating, wherein the mass fraction of GNS@PDA in the solid mass of the coating is 20wt%.

[0034] 2) Take 11g of GO and heat it to 200°C for 4 hours in a vacuum oven with a vacuum degree of -1bar to prepare RGO. Take 6.5g of RGO and 70.3g of anionic polyacrylate latex Yanbang 141 and disperse them under the action of ultrasonic waves in a water bath Even...

Embodiment 2

[0037] 1) Add 0.5 g of dopamine hydrochloride to 300 mL of Tris buffer and 100 mL of ethanol at room temperature, and use its self-polymerization reaction to modify 1 g of graphene under weak alkaline conditions (pH value=8.5). After 24 hours of reaction, Suction filtration and rinse with water to obtain GNS@PDA. Then take 0.4g of the above-prepared GNS@PDA and 10.3g of anionic polyacrylate latex Mage AR-1053 and disperse evenly under the action of ultrasonic waves in a water bath, and brush on a square polyimide substrate with a side length of 10cm. After drying, 0.45 mm thick polyacrylate / GNS@PDA coating, where the mass fraction of GNS@PDA in the solid mass of the coating is 10 wt%.

[0038] 2) Take 2g of GO and heat it to 200°C for 4 hours in a vacuum oven with a vacuum degree of -1bar to prepare RGO. Take 1.15g of RGO and 37.7g of anionic polyacrylate latex Mage AR-1053 under the action of ultrasonic waves in a water bath Disperse evenly, brush on the polyacrylate / GNS@PDA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com