Phase-change heat-conducting silicone grease containing macromolecular modifier and preparation method of phase-change heat-conducting silicone grease

A technology of phase change heat conduction and modifier, applied in the direction of chemical instruments and methods, heat exchange materials, etc., can solve problems such as brittle processing difficulties in electrical conduction, overheating of electronic devices, application limitations, etc., to improve interface compatibility and construction sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0037] Example 1 Preparation of two-dimensional hexagonal boron nitride / graphene heterostructure material

[0038] Add graphene oxide and two-dimensional hexagonal boron nitride with OH groups (mass ratio is 1:2) into deionized water (the mass ratio of water to graphene oxide and the total amount of two-dimensional hexagonal boron nitride is 100:1) , ultrasonically (700W) for 1 hour, then add dopamine (1% of the total mass of graphene oxide and two-dimensional hexagonal boron nitride), stir (1000r / min) for 10 minutes, and then add Tris-HCl buffer solution to adjust pH to 8.5 (Tris is trishydroxymethylaminomethane), and heated to 60°C and stirred (1000r / min) for 3 hours, filtered, dried at 100°C, and finally transferred to a CVD furnace, heated to 1000°C under nitrogen protection ℃ and maintained for 2 hours, and finally cooled naturally to room temperature to obtain a two-dimensional hexagonal boron nitride / graphene heterostructure material.

Embodiment 2

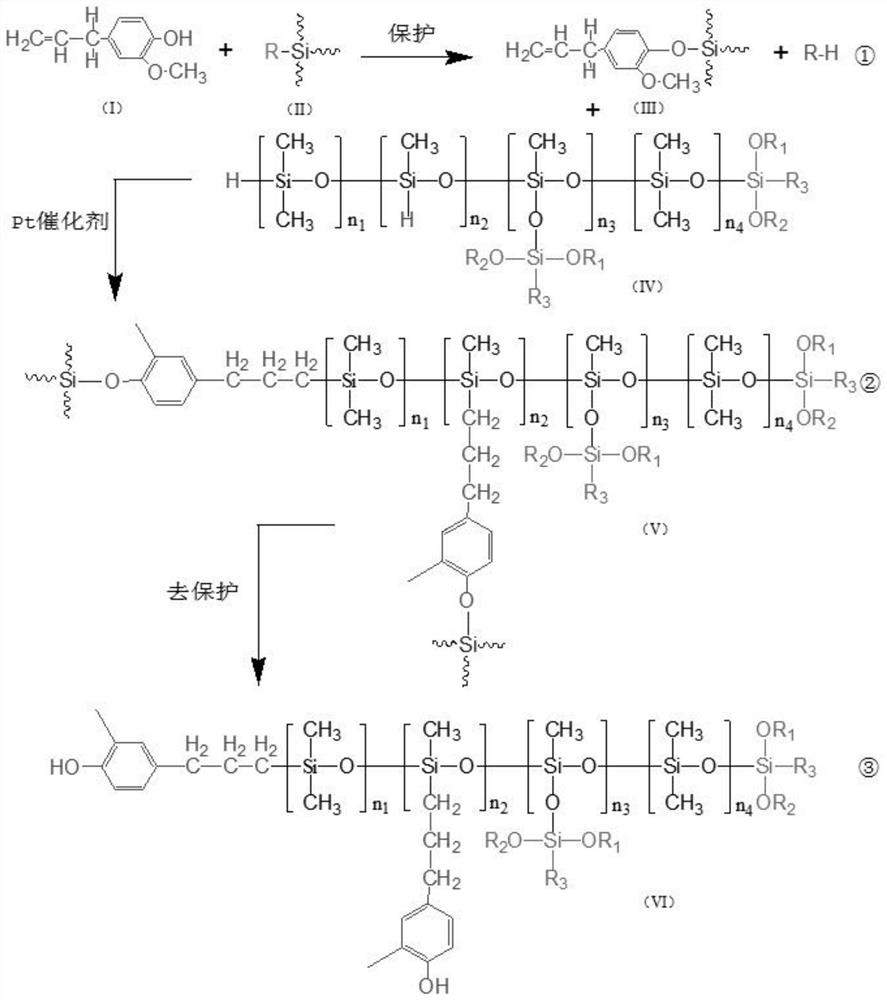

[0039] The preparation of embodiment 2 macromolecule modifiers

[0040] according to figure 1 As shown in the synthetic route map, with the eugenol shown in formula (I) and the hydrogen-containing siloxane shown in formula (IV) as main raw material, utilize the protection of phenolic hydroxyl group and deprotection method, under the effect of Pt catalyst , a novel macromolecular modifier containing both long-chain alkylsiloxane segments and phenolic hydroxyl functional groups was synthesized by hydrosilylation. Among them, R is a halo group, R 1 and R 2 C1-C2 alkyl, R 3 C8-C32 long-chain alkyl, n 1 , n 2 , n 3 , n 4 It is an integer of 20-100.

[0041] When R is Cl (chlorine), R 1 is C1 alkyl, R 2 is C2 alkyl, R 3 is C16 alkyl, n 1 , n 2 , n 3 , n 4 When being 20,40,40,20 respectively, the structural formula of this macromolecule modifier is as follows:

[0042]

[0043] The preparation method of the above-mentioned macromolecule modifier specifically includ...

Embodiment 3

[0047] Embodiment 3 A kind of phase-change heat-conducting silicone grease containing macromolecule modifier

[0048] The phase-change heat-conducting silicone grease is composed of the following raw materials in parts by weight:

[0049] 250 parts of 500cps methyl silicone oil, 1500 parts of aluminum oxide, 300 parts of the two-dimensional hexagonal boron nitride / graphene heterostructure material compound of Example 1, 40 parts of phase change material paraffin, and the macromolecular modifier of Example 2 10 servings.

[0050] The preparation method is: put 500cps methyl silicone oil and paraffin at 80-90°C for 10min under vacuum and stir at a stirring speed of 2000rpm; then add 10μm spherical alumina, two-dimensional hexagonal boron nitride / graphene heterostructure material and macromolecule Modifier, stirred in vacuum for 2 hours at a stirring speed of 2000rpm; then heated up to 110°C, vacuumed to remove water and low molecules, stirred for 20 minutes; finally cooled to r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com