Flavored syrup and preparation method thereof

A technology of syrup and flavor, applied in hydrazone preparation, confectionery, confectionary industry, etc., can solve the problems of easy crystallization and precipitation of preservatives, toxic and side effects, and difficulty in redissolving, and achieve safe and non-toxic antibacterial activity, exert antiseptic effect, The effect of high antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

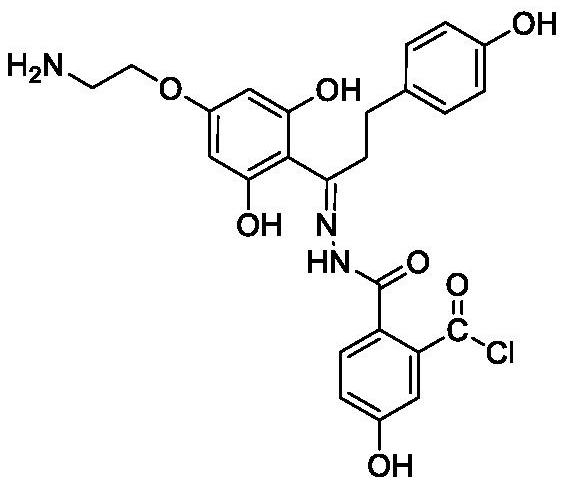

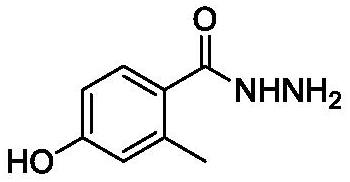

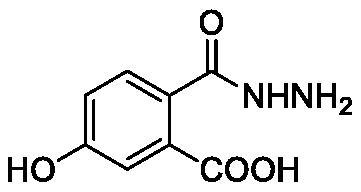

[0040] The present embodiment provides a chitosan oligosaccharide-based preservative, which is made by the following steps:

[0041] Step A1. Put 0.05 mol of phloretin derivatives in a three-necked flask, add 20 mL of thionyl chloride and 120 mL of DMF, and heat up to reflux for 3 hours. After the reaction, remove DMF and excess thionyl chloride by rotary evaporation to obtain acid chloride Derivatives of corticosteroids;

[0042] Step A2, put 10g of chitosan oligosaccharide in 120mL of acetic acid solution with a mass fraction of 1%, then add 100mL of methanol and stir evenly, transfer it to a three-necked flask, raise the temperature to 60°C, add 120mL of benzaldehyde methanol solution dropwise, and keep the temperature for 2h After the reaction, cool to room temperature, add 5% sodium hydroxide solution to adjust the pH value to 7.0, continue to stir until no flocculent precipitates are produced, filter with suction, collect the precipitate, and remove the precipitate with ...

Embodiment 2

[0051] The present embodiment provides a chitosan oligosaccharide-based preservative, which is made by the following steps:

[0052] Step A1. Put 0.05 mol of phloretin derivatives in a three-necked flask, add 22 mL of thionyl chloride and 140 mL of DMF, and heat up to reflux for 3 hours. After the reaction, remove DMF and excess thionyl chloride by rotary evaporation to obtain acid chloride Derivatives of corticosteroids;

[0053] Step A2, put 11g of chitosan oligosaccharide in 120mL of acetic acid solution with a mass fraction of 1%, then add 100mL of methanol and stir evenly, then transfer to a three-necked flask, raise the temperature to 60°C, add 120mL of benzaldehyde methanol solution dropwise, and keep the temperature for 2h After the reaction, cool to room temperature, add 5% sodium hydroxide solution to adjust the pH value to 7.0, continue to stir until no flocculent precipitates are produced, filter with suction, collect the precipitate, and remove the precipitate wit...

Embodiment 3

[0062] The present embodiment provides a chitosan oligosaccharide-based preservative, which is made by the following steps:

[0063] Step A1. Put 0.05mol of phloretin derivatives in a three-necked flask, add 25mL of thionyl chloride and 150mL of DMF, heat up to reflux for 3 hours, and after the reaction, remove DMF and excess thionyl chloride by rotary evaporation to obtain acid chloride Derivatives of corticosteroids;

[0064] Step A2, put 12g of chitosan oligosaccharide in 120mL of acetic acid solution with a mass fraction of 1%, then add 100mL of methanol and stir evenly, then transfer to a three-necked flask, raise the temperature to 60°C, add 120mL of benzaldehyde methanol solution dropwise, and keep the temperature for 2h After the reaction, cool to room temperature, add 5% sodium hydroxide solution to adjust the pH value to 7.0, continue to stir until no flocculent precipitates are produced, filter with suction, collect the precipitate, and remove the precipitate with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com