Cerebroprotein hydrolysate, preparation method thereof and composition containing cerebroprotein hydrolysate

A brain protein hydrolyzate and hydrolyzate technology, which is applied in the field of food processing, can solve the problems of decreased yield of active peptides, large amount of solvent usage, increased cost, etc., and achieve the effects of improving extraction rate, simplifying production process, and reducing use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

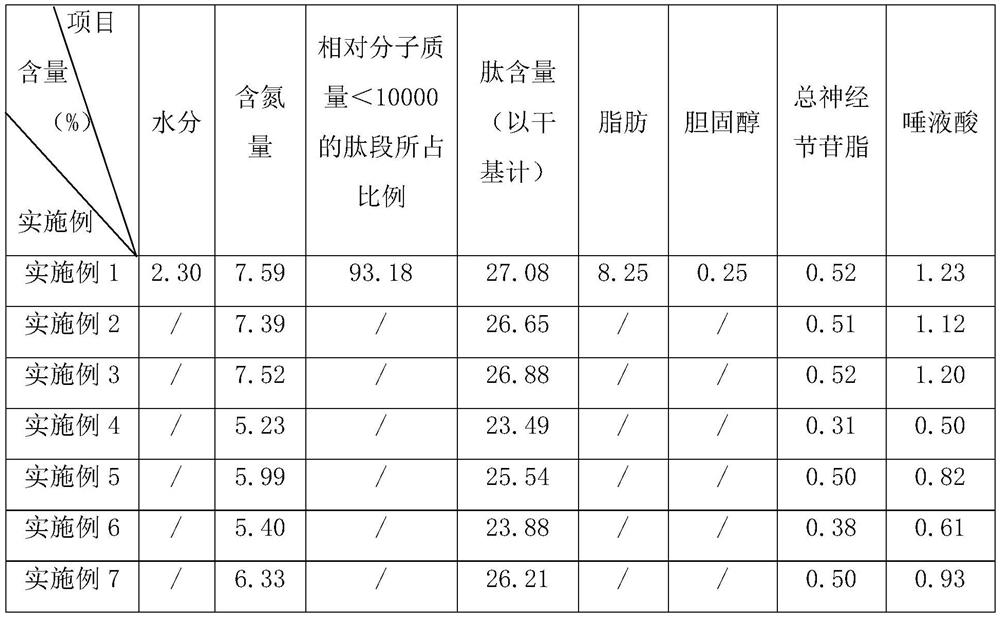

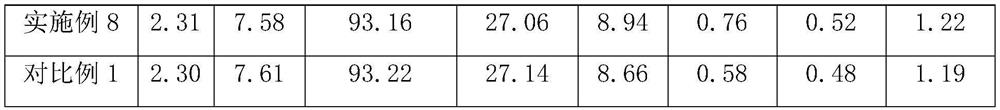

Examples

preparation example Construction

[0053] The present application provides a method of preparing an brain hydrolyzate, including the following steps:

[0054] S1, tissue homogenization: After cleaning the animal brain, remove the meningum and blood vessels, rinse the surface with deionized water, add 2-3 times of deionized water by weight of the animal brain, and then rubbed twice with colloidal grinding. Extremely spray;

[0055] S2, passivation enzyme activity: After boiling the homogenate, maintain 20-40 min, to passivate the enzyme activity and sterilize the animal brain tissue, and then cool the pretreative homogenate;

[0056] S3, enzymatic hydrolysis: The pretreatment homogenate is added to the protease, the adjustment system pH is 6.5-7.5, and the temperature is 55-60 ° C, and the temperature is stirred under temperature under this condition, hydrolyzing hydrolysis is 6-12 h, resulting in an enzymatic hydrolyzide; wherein the protease is papaya. The weight ratio of protease and trypsin and ponybain and anim...

Embodiment 1

[0067] Example 1: A method of preparing an brain hydrolyzate comprising the steps of:

[0068] S1, tissue homogenate: After cleaning fresh pig brain, remove the meningum and blood vessels, flush the surface with deionized water, add 2 times deionized water in the weight of the pig brain, and then rub it twice with colloidal grinding. Homogenate;

[0069] S2, passivation enzyme activity: After boiling the homogenate, maintained for 30 min to passivate the enzyme activity of the pork brain and sterilized, and then preprocessing homogenate after cooling;

[0070] S3, enzymatic solution: Add a protease in the pretreatment homogenate, the adjustment system pH is 7.0, the temperature is 58 ° C, and the temperature is stirred under temperature under this conditions, and the enzymatic hydrolyzate is obtained; wherein the protease is a papain protease and trypsin, papaya The weight ratio of protease and pig brain is 0.3: 100, the weight ratio of trypsin and the pig brain is 0.4: 100;

[00...

Embodiment 2

[0078] The difference from the first embodiment is that the protease in S3 is a papain protease and trypsin, the weight ratio of papain protease and the pig brain is 0.5: 100, the weight ratio of trypsin and the pig brain is 0.3: 100.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com