Electromagnetic shielding composite foam with oriented filler structure and preparation method thereof

A technology of electromagnetic shielding and composite foam, applied in the direction of magnetic/electric field shielding, electrical components, etc., can solve the problems of large amount of conductive filler, high preparation cost, and limited application, and achieve low cost, simple operation, and enhanced lap joints The effect of access

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method of making an electromagnetic shield oriented structured packing having a composite foam, comprising the steps of:

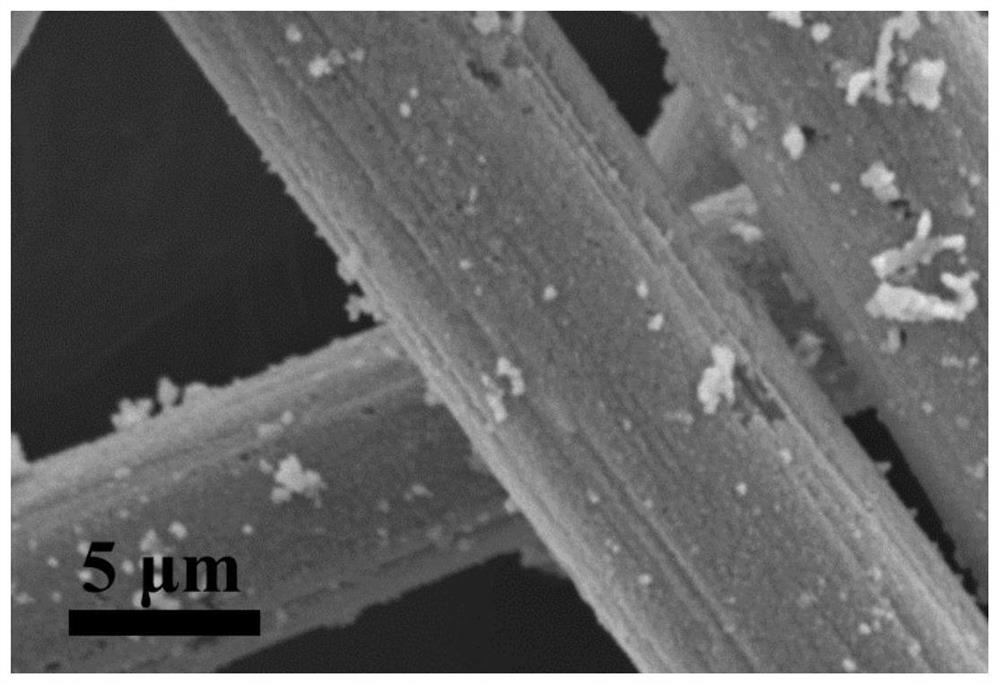

[0032] Preparation (1) of the magnetic conductive particles

[0033] The aramid fibers were added to 1g of dilute sulfuric acid 50mL, IH mechanically stirred, washed and filtered repeatedly with distilled water to neutral, then added to an aqueous solution of stannous chloride and subjected to mechanical stirring after sensitization aryl nylon fibers were added to 100mL of plating liquid iron (ferric sulfate 10g / L, gentiobiose 5g / L), sodium citrate solution was slowly added, the reaction stirred for 10h under magnetic force, by washing, filtration, and dried to obtain metallic iron aramid fiber load magnetic conductive particles.

[0034] (2) loading metallic iron aramid fiber - Preparation of polyethylene composites

[0035] 8g of polyethylene and an aramid fiber load 1g iron metal magnetic conductive particles is placed under 5min blend mixer at...

Embodiment 2

[0041] A method of making an electromagnetic shield oriented structured packing having a composite foam, comprising the steps of:

[0042] Preparation (1) of the magnetic conductive particles

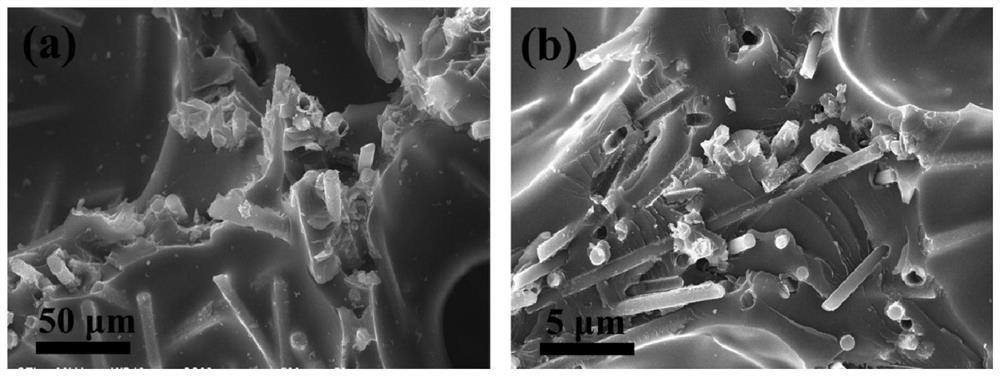

[0043] The dilute sulfuric acid was added to 1g 10mL carbon fibers, the mechanical stirring 2h, filtered and washed repeatedly with distilled water to neutral, then it was added to an aqueous solution of stannous chloride and subjected to mechanical stirring, after the carbon fibers are added to the sensitized 50mL of chemical nickel plating solution (nickel sulfate 40g / L, sodium pyrophosphate 10g / L, sodium hypophosphite 5g / L, thiourea 5g / L, ammonia 5 mL) was slowly added an aqueous solution of sodium citrate, under magnetic stirring the reaction 10min, by washing, filtration, and dried to give metallic nickel particles are supported magnetic conductive carbon fibers.

[0044] (2) supported metallic nickel - carbon fiber epoxy composite was prepared

[0045] 10g of epoxy resin and 0...

Embodiment 3

[0051] A method of preparing an electromagnetic shield composite foam having an alignment filler structure, comprising the steps of:

[0052] (1) Preparation of magnetic conductive particles

[0053] 1G basalt fibers were added to 20 mL of dilute sulfuric acid, mechanically stirred for 1 h, washed repeatedly with distilled water and filtered to neutral, and then added to aqueous solution of tin chloride and mechanically stirred, and the sensitized basalt fiber Add to 100 mL of chemical plating solution (40 g / L of sulfate, 5 g / L of tartaricate 20g / L, sodium phosphate 2 g / l, boric acid 10 g / L, ammonia water 5 mL), slowly add aqueous sodium citrate solution, in magnetic force The reaction was allowed to obtain a metal cobalt-loaded basalvan fiber magnetic conductive particles by washing, filtration, and dried to obtain metal cobalt loaded basalt fiber magnetic conductive particles.

[0054] (2) Preparation of metal cobalt load basalt fiber-polyurethane elastomer composites ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com