Preparation method of high-capacity single-crystal positive electrode battery material and product

A positive battery, high-capacity technology, applied in the growth of polycrystalline materials, positive electrodes, single crystal growth, etc., can solve the problems of difficult lithium ion diffusion, limit the development of single crystal materials, etc., to improve the diffusion rate, stability and cycle. Good performance and the effect of increasing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

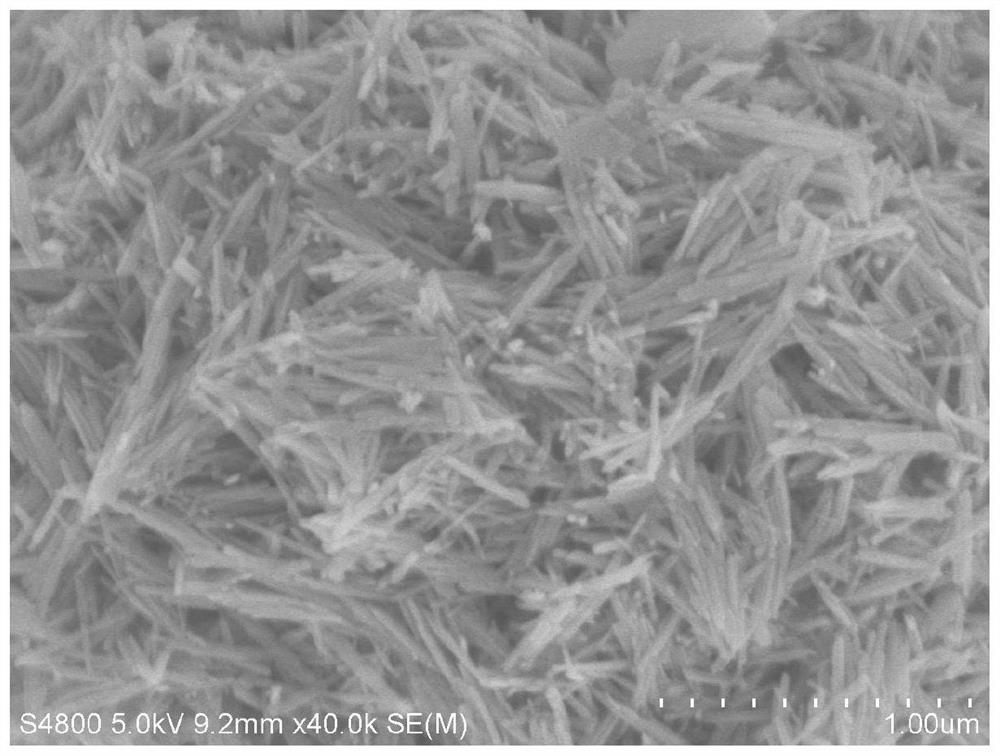

Image

Examples

preparation example Construction

[0027] The preparation method in the above-mentioned embodiment specifically includes the following steps:

[0028] (1) Prepare the solution of the iron source, nickel source, cobalt source, manganese source, ferrous source, and magnesium source in container a in proportion; then prepare the nickel source, cobalt source, and manganese source of battery level in proportion The solution is in container b;

[0029] Iron source in container a: nickel source: cobalt source: manganese source: ferrous source: magnesium source molar ratio should be 0.2~6:1:1:1:1:1; nickel source in container b: cobalt source: manganese source mole The ratio should be 6~9:0.5~2.5:0.5~2.5; the molar ratio of the total metal cations in container a to the total metal cations in container b should be 1:4~30;

[0030] The iron source can be battery-grade sulfate, nitrate or chloride corresponding to +3 valence; the nickel source, cobalt source, manganese source, ferrous source, and magnesium source can be ...

Embodiment 1

[0040] (1) Prepare battery grade 3mol ferric sulfate, 1mol nickel sulfate, 1mol cobalt sulfate, 1mol manganese sulfate, 1mol ferrous sulfate, 1mol magnesium sulfate solution in container a in proportion; prepare battery grade nickel sulfate 26.4mol, cobalt sulfate 8.8 mol, manganese sulfate 8.8mol solution in container b;

[0041] (2) Add all the solution in container a into reactor A and stir, then add 2L of 12mol / L sodium hydroxide solution to reaction vessel A, control the reaction pH at 12.5, and continue stirring for 10h after adding the sodium hydroxide solution; Finally, add the container b solution, 2.2L of 10mol / L ammonia water, and 6mol / L sodium hydroxide solution into reactor A, control the reaction pH at 11, wash the obtained slurry, filter and dry to obtain powder d;

[0042] (3) Fully mix the powder d obtained in step (2) and 60.5 mol of lithium source, put them into a tube furnace and heat at 4°C / min to 850°C, keep it warm for 8h, during which an oxygen atmosphe...

Embodiment 2

[0044] (1) Prepare battery grade 1.5mol ferric sulfate, 1mol nickel sulfate, 1mol cobalt sulfate, 1mol manganese sulfate, 1mol ferrous sulfate, 1mol magnesium sulfate solution in container a; prepare battery grade nickel sulfate 67.2mol, cobalt sulfate A solution of 19.2mol and 9.6mol of manganese sulfate is in container b;

[0045] (2) Add all the solution in container a to reactor A and stir, then add 2.94L of 6mol / L sodium hydroxide solution to reaction container A, control the reaction pH at 12, continue stirring for 18h after adding the sodium hydroxide solution ; Finally, add the container b solution, 6mol / L ammonia water 3.2L, and 12mol / L sodium hydroxide solution into the reactor A, control the reaction pH at 11.5, wash the obtained slurry, filter and dry to obtain powder d;

[0046] (3) Fully mix the powder d obtained in step (2) and 108.2 mol of lithium source, put them into a tube furnace and heat to 760°C at 1°C / min, keep warm for 2h, during which an oxygen atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial length | aaaaa | aaaaa |

| Radial width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com