Preparation method and application of novel water-soluble acne-removing composite material

A composite material and water-soluble technology, which is applied in the field of skin care products, can solve the problems of poor compounding ability of surfactants and drug leakage, etc., and achieve the effect of good acne removal effect, improved absorption speed, and easy absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

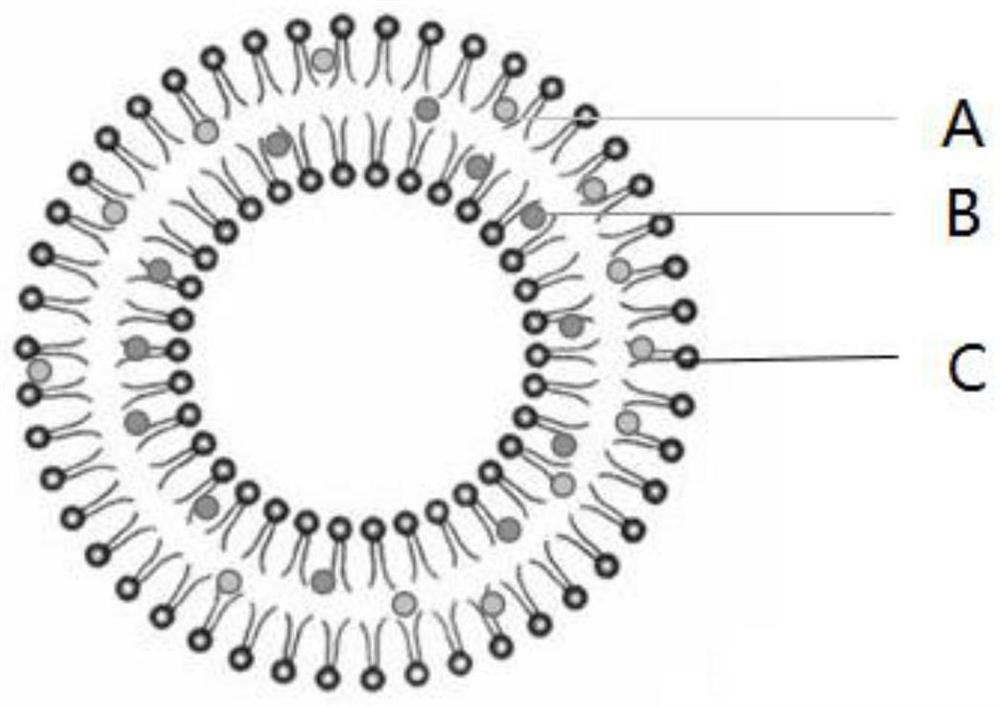

Method used

Image

Examples

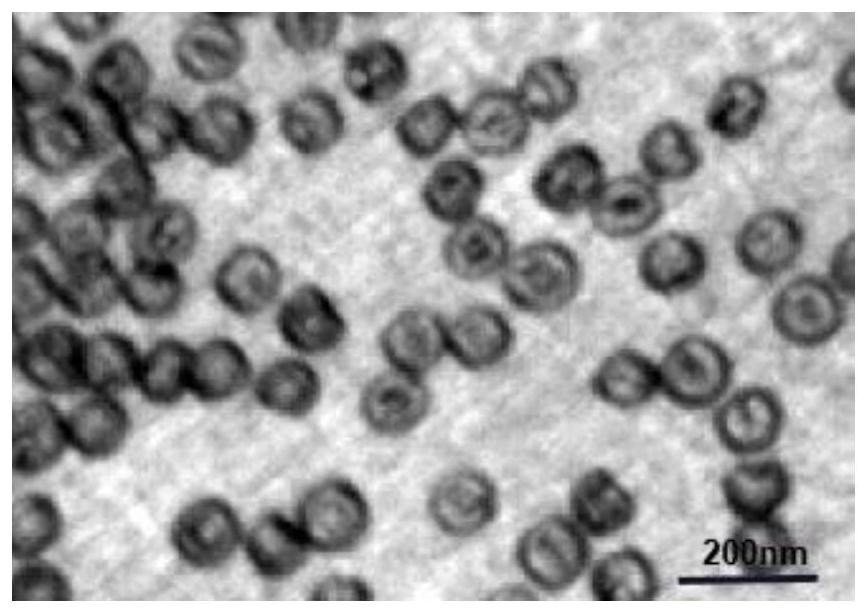

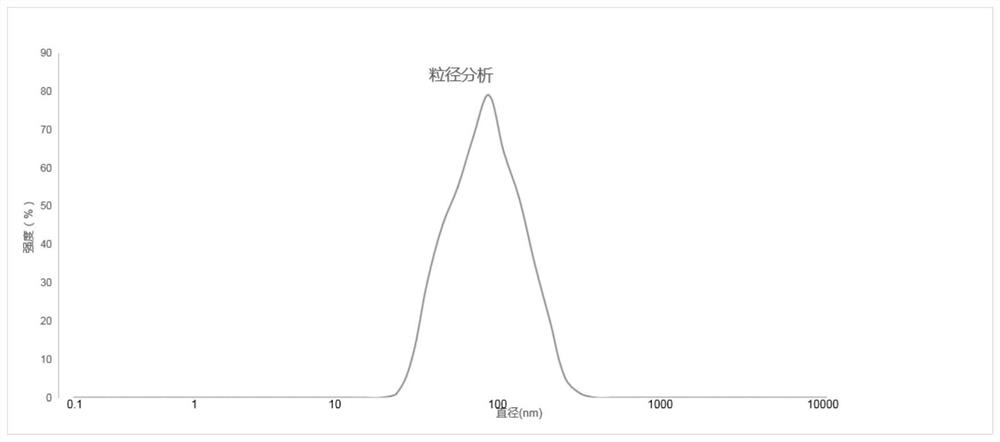

Embodiment 1

[0033] Weigh 20mg of poloxamer 407, 20mg of lecithin, 20mg of cholesterol, 10mg of PEG2000, 50mg of sodium hyaluronate, 100mg of white root extract, 100mg of salvia miltiorrhiza extract, 100mg of eucommia leaf extract, and 100mg of licorice extract in 50mL of two Methyl chloride was used as the organic phase, stirred and mixed at 3000rpm to form colostrum; then 200mg cymene was weighed and dissolved in 37mL phosphate buffered saline (PBS) as the water phase; the colostrum was quickly injected into the rapidly stirred water phase with a syringe , the speed of rapid stirring is 4000rpm, forms double emulsion, and the double emulsion that forms is concentrated under reduced pressure on rotary evaporator to remove residual dichloromethane, and the residue adjusts the solution volume to 100mL with PBS, promptly obtains primary liposome; After the liposomes were ultrasonically treated for 30 minutes and left to stand at room temperature for 12 hours, a single-chamber liposome with un...

Embodiment 2

[0036] Weigh 1 mg poloxamer 407, 1 mg lecithin, 1 mg cholesterol, 1 mg PEG2000, 1 mg sodium hyaluronate, 1 mg white root extract, 1 mg salvia miltiorrhiza extract, 1 mg Eucommia leaf extract, 1 mg licorice extract and dissolve in 50 mL distilled water Methyl chloride was used as the organic phase, stirred and mixed at 2800rpm to form colostrum; then 100mg cymene was weighed and dissolved in 37mL phosphate buffered saline (PBS) as the water phase; the colostrum was quickly injected into the rapidly stirred water phase with a syringe , the speed of rapid stirring is 1000rpm, forms double emulsion, and the double emulsion that forms forms is concentrated under reduced pressure on rotary evaporator to remove residual dichloromethane, and the residue is adjusted to 10mL with PBS solution volume, promptly obtains primary liposome; Primary liposome is obtained; After the liposomes were ultrasonically treated for 20 minutes and left to stand at room temperature for 10 hours, a single-c...

Embodiment 3

[0038] Weigh 100mg poloxamer 407, 100mg lecithin, 100mg cholesterol, 100mg PEG2000, 100mg sodium hyaluronate, 50mg white root extract, 50mg salvia miltiorrhiza extract, 50mg Eucommia leaf extract, 50mg licorice extract and dissolve in 50mL Methyl chloride was used as the organic phase, stirred and mixed at 3200rpm to form colostrum; then 150mg cymene was weighed and dissolved in 37mL phosphate buffered saline (PBS) as the water phase; the colostrum was quickly injected into the rapidly stirred water phase with a syringe , the speed of rapid stirring is 3000rpm, forms double emulsion, and the double emulsion that forms forms is concentrated under reduced pressure on the rotary evaporator to remove residual dichloromethane, and the residue is adjusted to 50mL with PBS solution volume, promptly obtains primary liposome; After the liposomes were ultrasonically treated for 40 minutes and left to stand at room temperature for 14 hours, a single-chamber liposome with uniform particle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com