Resin composition, prepreg, laminated board and printed wiring board

A technology of resin composition and prepreg, which is applied in the fields of printed circuit boards, prepregs, and resin compositions containing modified active ester compounds, to achieve the effect of increasing the cross-linked network structure, reducing the dielectric loss value and improving the brittleness problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

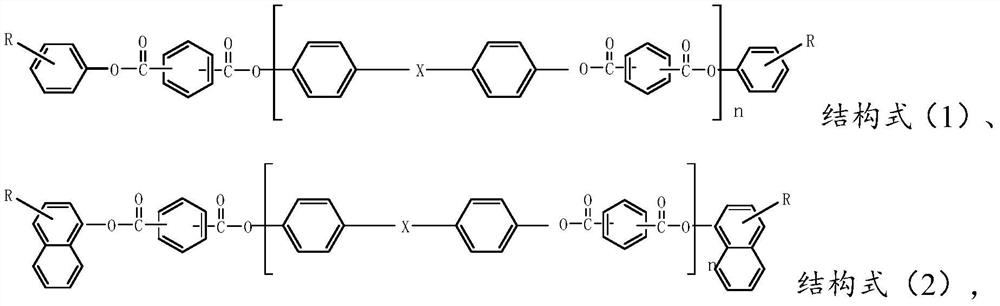

[0046] Take the preparation of the active ester compound containing butadiene group as an example below, and its reaction mechanism is as follows:

[0047]

[0048]Of course, it is not limited to this, other methods can also be used to prepare active ester compounds as shown in structural formula (1) and structural formula (2), that is, all can be prepared as shown in structural formula (1) and structural formula (2) The preparation methods of the active ester compounds shown are all within the protection scope of the present invention.

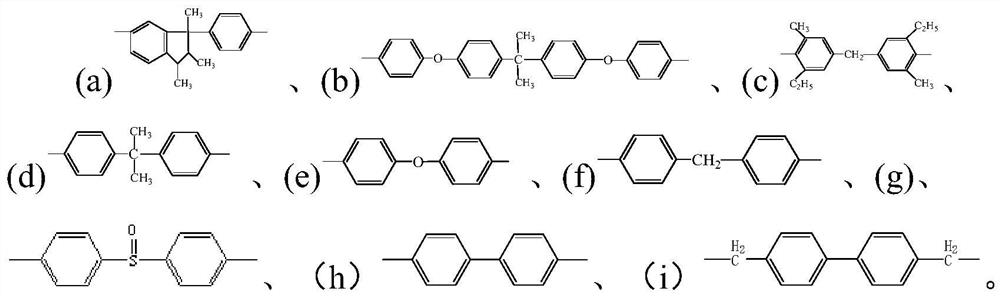

[0049] Further, the epoxy resin is selected from bisphenol A epoxy resin, bisphenol F epoxy resin, bisphenol S type epoxy resin, bisphenol E type epoxy resin, phosphorus-containing epoxy resin, nitrogen-containing epoxy resin Resin, o-cresol novolac epoxy resin, bisphenol A novolac epoxy resin, phenol novolac epoxy resin, cresol novolac epoxy resin, triphenylmethane epoxy resin, tetraphenylethane epoxy resin, biphenyl type Epoxy resin, na...

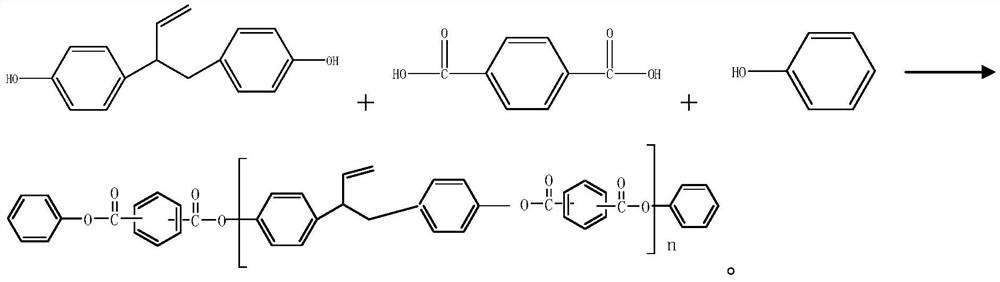

Synthetic example 1

[0116] Take butadiene-based bisphenol resin and benzenedicarboxylic acid, stir and dissolve in toluene solvent evenly. The concentration is 20% sodium hydroxide aqueous solution, react for 2.5 hours, then add phenol, continue to react for 1 hour, after the reaction is completed and after several times of washing, dry under vacuum conditions at 80°C for 3 hours to obtain the active ester compound A , its chemical structure is as follows:

[0117]

Synthetic example 2

[0119] Take pentadienyl phenol resin and benzenedicarboxylic acid, stir and dissolve in toluene solvent evenly. 20% aqueous sodium hydroxide solution, reacted for 2.5 hours, then added p-vinylphenol, continued to react for 0.5 hours, after the reaction was completed and washed several times, dried under vacuum conditions at 80°C for 3 hours to obtain the active ester compound B, its chemical structural formula is as follows:

[0120]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com