Process method for processing ZrAlO film system on cavity surface of semiconductor chip

A process method and semiconductor technology, applied in semiconductor lasers, metal material coating process, ion implantation plating, etc., can solve the problem of affecting the mechanical properties and adhesion of the film layer, affecting the service life and reliability, affecting the reliability of the laser, etc. problems, to achieve the effect of improving long-term aging ability and antistatic properties, improving product competitiveness and service life, good mechanical properties and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

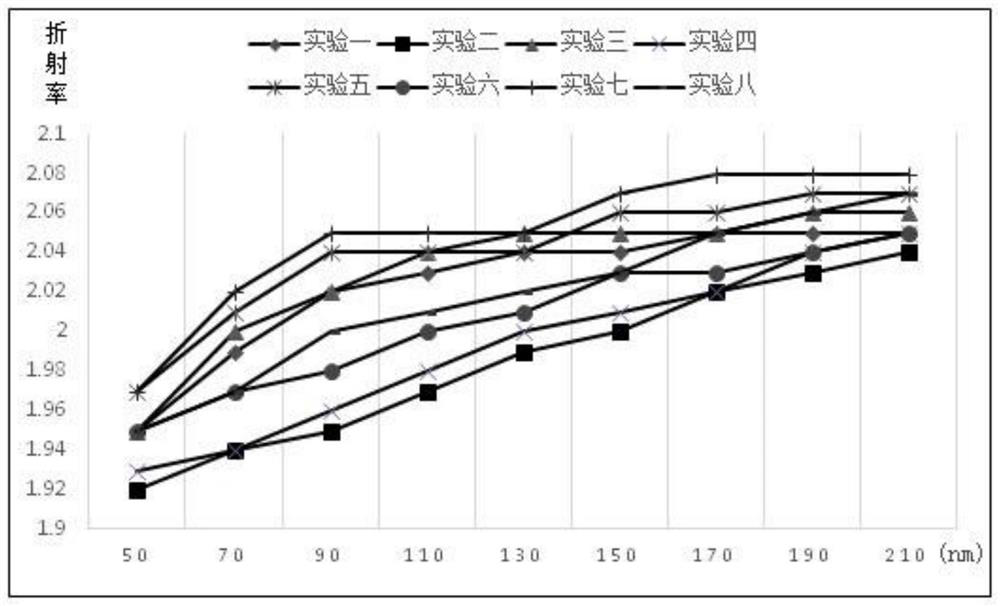

[0049] The following ZrAlO and ZrO 2 The above-mentioned process methods are used for coating under different temperature and film thickness conditions, that is, ZrAlO film coating is performed on the surface of the light cavity, and ZrO 2 The film is coated, and then the refractive index of the companion plate is tested using an ellipsometer.

[0050] Specifically, it is prepared in four groups:

[0051] 1) With the coating environment temperature as 160°C, the coating thickness (referring to ZrAlO film layer or ZrO 2 film thickness) are 50nm, 70nm, 90nm, 110nm, 130nm, 150nm, 170nm, 190nm, 210nm process conditions, using ZrAlO and ZrO 2 The film material is used for coating, and the accompanying sheet is placed with the furnace. Among them, ZrAlO is recorded as Experiment 1, and ZrO 2 Denoted as Experiment 2;

[0052] 2) The coating environment temperature is 180°C, and the coating thickness is 50nm, 70nm, 90nm, 110nm, 130nm, 150nm, 170nm, 190nm, 210nm process conditions,...

Embodiment 2

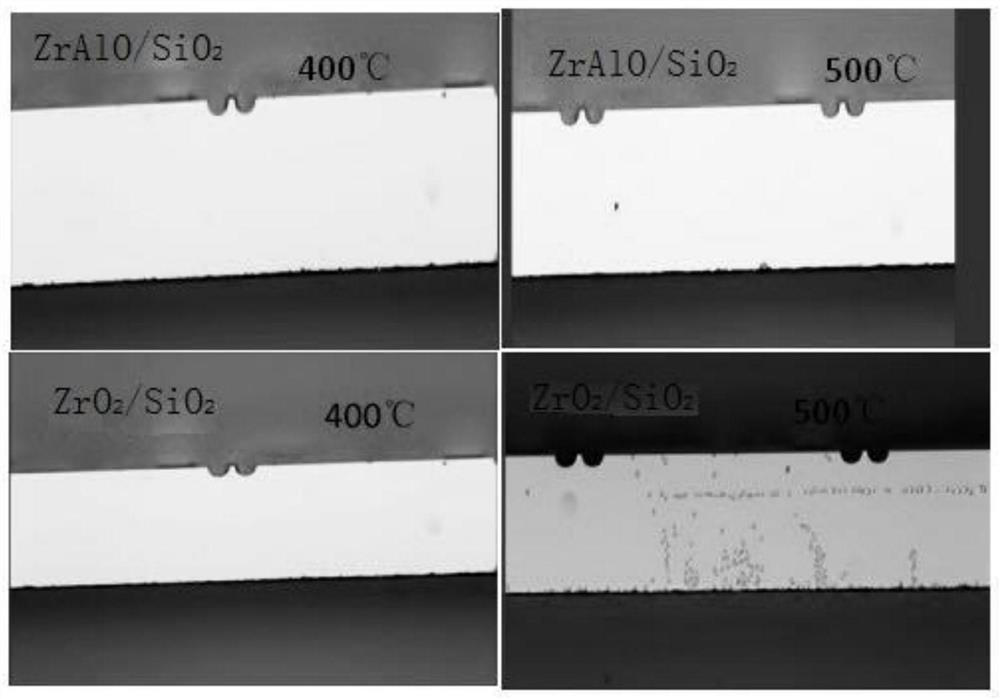

[0057] In this embodiment, the product is prepared according to the above-mentioned processing method, and the surface of the light exit cavity is coated with ZrAlO / SiO 2 Anti-reflection coating, coated with Al on the backlight 2 o 3 / Si / Al 2 o 3 The / Si film is a high-reflection film, and two Bar bars after the coating are randomly selected as the experimental group; the surface of the optical cavity is coated with ZrO 2 / SiO 2 Anti-reflection coating, coated with Al on the backlight 2 o 3 / Si / Al 2 o 3 The / Si film is a high-reflection film, and two Bar bars after coating are randomly selected as the control group. The experimental group and the control group are the same except for the anti-reflection film on the surface of the light cavity, and the other processes are the same.

[0058] Put the sampled bars of the experimental group and the control group into the alloy furnace to heat up the alloy furnace rapidly and keep the temperature constant for a certain perio...

Embodiment 3

[0062] In this example, the SEM morphology detection of the product is carried out, and the product is prepared according to the above-mentioned processing method, and the surface of the light exit cavity is coated with ZrAlO / SiO 2 Anti-reflection coating, coated with Al on the backlight 2 o 3 / Si / Al 2 o 3 / Si film is a high-reflection film, randomly select 10pcs chips as the experimental group; the surface of the light cavity is coated with ZrO 2 / SiO 2 Anti-reflection coating, coated with Al on the backlight 2 o 3 / Si / Al 2 o 3 / Si film system high-reflection film, randomly select 10pcs chips as the control group; among them, the chips selected are tested and have normal appearance. The process methods are the same.

[0063] SEM morphology analysis was carried out on the light-emitting end and backlight end of the chips of the experimental group and the control group, as shown in the attached instructions. Figure 4 It can be seen from the appearance that the film s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com