Quasi-periodic large-area high-temperature-resistant infrared heat radiator and preparation method thereof

A heat radiator and high-temperature-resistant technology, applied in the direction of incandescent lamps, electrical components, incandescent lamp parts, etc., can solve the problems of radiation peak deviation, easy peeling, thick thickness, etc., and achieve the effect of fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

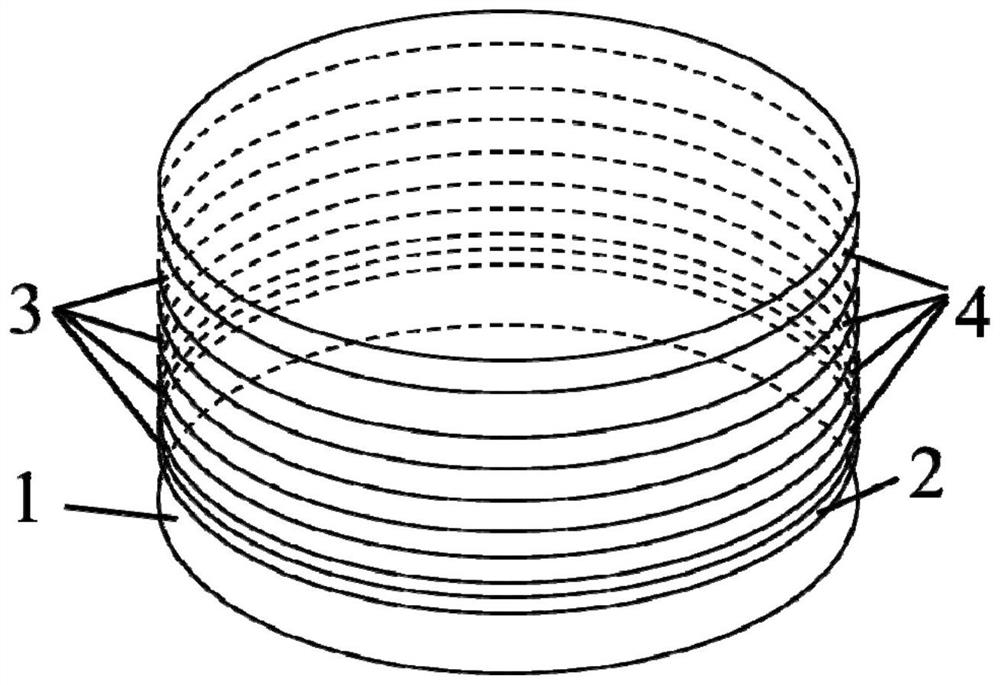

[0037] Such as figure 1 As shown, a structure diagram of a quasi-periodic large-area high-temperature-resistant infrared heat radiator: including a substrate 1, a metal layer (such as: chromium Cr) 2, a medium a (such as SiO 2 ) 3, medium b (such as Nb 2 o 5 )4, wherein, a) the thermal expansion coefficient of the substrate is small; b) the metal chromium Cr is resistant to high temperature and has strong adhesion; c) the dielectric material SiO 2 with Nb 2 o 5 High temperature resistance, its absorption coefficient in the mid-infrared band is close to 0, and the refractive index changes little with temperature, and the thermal expansion coefficient is small.

[0038] Infrared heat radiator preparation and radiation spectrum testing include the following steps:

[0039] Step 1: Grow a metal layer on the substrate by electron beam evapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com