Post-treatment method for improving stability of reverse osmosis membrane and reverse osmosis membrane product

A reverse osmosis membrane and stability technology, applied in the direction of osmosis/dialysis water/sewage treatment, reverse osmosis, semi-permeable membrane separation, etc., can solve the problems of decreased desalination rate, unqualified performance, high molecular viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

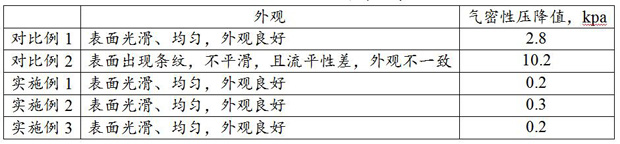

Examples

Embodiment 1

[0111] 1. PVA solution formula:

[0112] 3.0 parts of PVA particles;

[0113] 0.5 parts of sodium dodecylsulfonate;

[0114] 3.0 parts of simethicone oil;

[0115] 93.5 parts of RO water.

[0116] The PVA particles, surfactants, additives and water are stirred and heated to dissolve at 80° C. and 1200 rpm stirring speed to obtain a uniform and transparent PVA solution. Cool to 25°C and set aside.

[0117] 2. Post-processing process:

[0118] S1. Rinse the nascent reverse osmosis membrane through a rinsing tank. The rinsing solution is RO water at a temperature of 50° C. for 5 minutes.

[0119] S2. At an ambient humidity of 80% RH, pour the PVA solution on the surface of the reverse osmosis membrane, and use a roller to remove excess solution on the surface.

[0120] S3. Place in an oven and dry at 60° C. for 2 minutes to obtain a reverse osmosis membrane product with a smooth and uniform surface.

Embodiment 2

[0122] 1. PVA solution formula:

[0123] 3.0 parts of PVA particles;

[0124] 0.5 parts of sodium dodecylsulfonate;

[0125] 5.0 parts of polyacrylic acid;

[0126] 91.5 parts of RO water.

[0127] The PVA particles, surfactants, additives and water are stirred and heated to dissolve at 80° C. and 1200 rpm stirring speed to obtain a uniform and transparent PVA solution. Cool to 25°C and set aside.

[0128] 2, post-treatment process: with embodiment 1.

Embodiment 3

[0130] 1. PVA solution formula:

[0131] 3.0 parts of PVA particles;

[0132] 0.5 parts of sodium dodecylsulfonate;

[0133] 2.0 parts of sodium carboxymethylcellulose;

[0134] 94.5 parts of RO water.

[0135] The PVA particles, surfactants, additives and water are stirred and heated to dissolve at 80° C. and 1200 rpm stirring speed to obtain a uniform and transparent PVA solution. Cool to 25°C and set aside.

[0136] 2, post-treatment process: with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com