Chemical modification method for surface of dental implant combined with alveolar bone and application

A technology of dental implants and surface chemistry, applied in the field of biomedicine, can solve the problems of not fundamentally solving the problem of the combination of implants and alveolar bone, the performance of osseointegration is not improved, and the bonding force of the coating is not strong, etc. To achieve the effect of improving osseointegration performance, improving hydrophilicity, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The method for chemical modification of the surface of the dental implant combined with the alveolar bone provided in this embodiment, the steps are as follows:

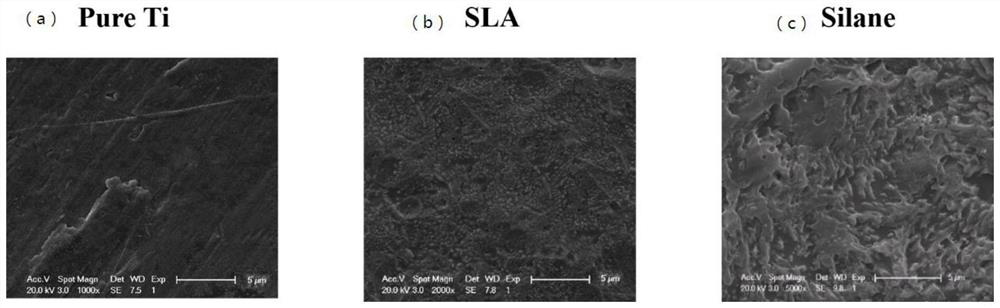

[0030] (1) Material preparation: Polish a cylindrical pure titanium sheet (PureTi) with a diameter of 6 mm and a thickness of 3 mm with a gradient rough sandpaper from coarse to fine to mirror brightness (60#, 200#, 600#, 1000#, 2000#), followed by ultrasonic cleaning in an ultrasonic cleaner for 10 minutes with deionized water, absolute ethanol, and deionized water.

[0031] (2) Preparation of hydrofluoric acid / nitric acid mixed etching solution: pipette 2ml of 40% hydrofluoric acid and 4ml of concentrated nitric acid into 40ml of deionized water, place on a magnetic stirrer and mix evenly.

[0032] (3) Preparation of hydrochloric acid / sulfuric acid mixed acid etching solution: pipette 1ml of concentrated hydrochloric acid and 1ml of concentrated sulfuric acid into 40ml of deionized water, place on a magnetic...

Embodiment 2

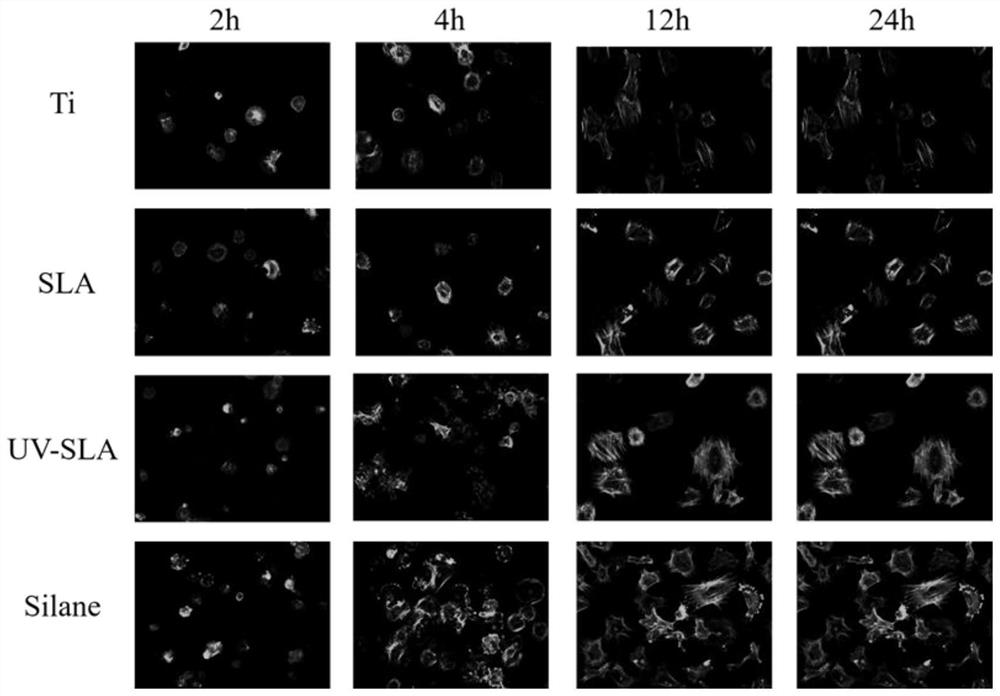

[0042] Cell Adhesion Test

[0043] (1) Silane in Example 1 that had been sterilized was used as the experimental group, PureTi, SLA and UV were used as the control group, and 3 slices were taken from each group as parallel samples, and put into a 48-well plate, 1 slice per hole.

[0044] (2) The 2nd-4th generation rat bone marrow mesenchymal stem cells (BMSCs) were mixed with 5×10 4 / ml cell density seeded on the surface of the titanium sheet, placed at 37 ° C, 5% CO 2 cultured in an incubator.

[0045] (3) 2h, 4h, 12h and 24h after cell inoculation, take out the 48-well plate, remove the original culture medium, and wash with phosphate buffer saline (PBS).

[0046] (4) Add 4% paraformaldehyde to each well and fix at room temperature for 10 min.

[0047] (5) Remove paraformaldehyde in the wells, wash with PBS, and wash 2-4 times with PBS containing 0.1% Triton X-100 at room temperature, about 5 minutes each time.

[0048] (6) Dilute Actin-Tracker Green with PBS containing ...

Embodiment 3

[0054] Cell Viability and Proliferation Assays

[0055] (1) CCK-8 detection:

[0056] (1) The sterilized Silane in Example 1 was used as the experimental group, and PureTi, SLA, and UV were used as the control group. Each group took 3 slices as parallel samples and put them into a 48-well plate, with 1 slice per hole.

[0057] (2) The 2nd-4th generation rat bone marrow mesenchymal stem cells (BMSCs) were mixed with 5×10 4 / ml cell density seeded on the surface of the titanium sheet, placed at 37 ° C, 5% CO 2 cultured in an incubator.

[0058] (3) Prepare CCK-8 solution according to the ratio of CCK-8: complete medium = 1:10.

[0059] (4) Take out the 48-well plate on, 3, 5, and 7 days respectively, remove the original culture medium, and wash with PBS.

[0060] (5) 500 μL of the prepared CCK-8 solution was added to each well, and placed in an incubator for further incubation for 2 hours.

[0061] (6) Take out the well plate, pipette 100 μL per well, transfer to a 96-well ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com