Oxygen adsorbent, preparation method and method for reducing oxygen content in nitrous oxide feed gas

A nitrous oxide and adsorbent technology, applied in the field of gas purification, can solve the problems of low quality of nitrous oxide, and achieve the effects of good activity, improved purity and simple conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Preparation of borosiloxane containing silicon hydrogen structure:

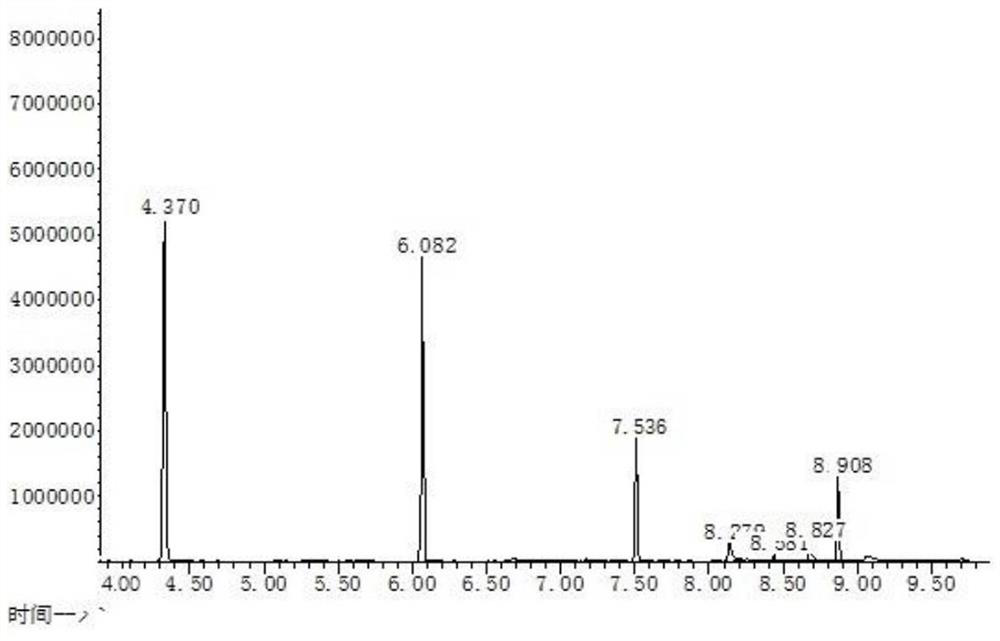

[0047] Under the protection of nitrogen, 1.22g (10mmol) of phenylboronic acid was dissolved in 50ml of tetrahydrofuran, and then a mixture of 5.56g (50mmol) of methyldichlorosilane and 20ml of tetrahydrofuran was added dropwise, and the reaction solution was obtained after 3 hours at room temperature. Then the reaction solution was added dropwise to a suspension containing 5g of zinc oxide and 500ml of ethyl acetate, and after reacting at room temperature for 12 hours, the zinc salt was removed by filtration, and the filtrate was washed with water and evaporated to remove tetrahydrofuran to obtain a mixed borosiloxane 2.53 g (yield 78.8%), its gaseous analysis GC diagram is shown in figure 2 shown.

[0048] Preparation of borosiloxane containing vinyl structure:

[0049] Under the protection of nitrogen, 1.22g (10mmol) of phenylboronic acid was dissolved in 50ml of tetrahydrofuran, and then a mixtur...

Embodiment 1

[0051] A kind of preparation method of oxygen adsorbent, the preparation method of described oxygen adsorbent is as follows:

[0052] (1) Disperse 1.5g of manganese oxide powder into 100ml of toluene to form a dispersion;

[0053] (2) Dissolve 10g of borosiloxane containing silicon hydrogen structure and 8g of borosiloxane with vinyl structure in the above dispersion liquid respectively, add 5mg of chloroplatinic acid to it, stir and react at 85°C for 4h to obtain Polyborosiloxane gel coated with manganese oxide;

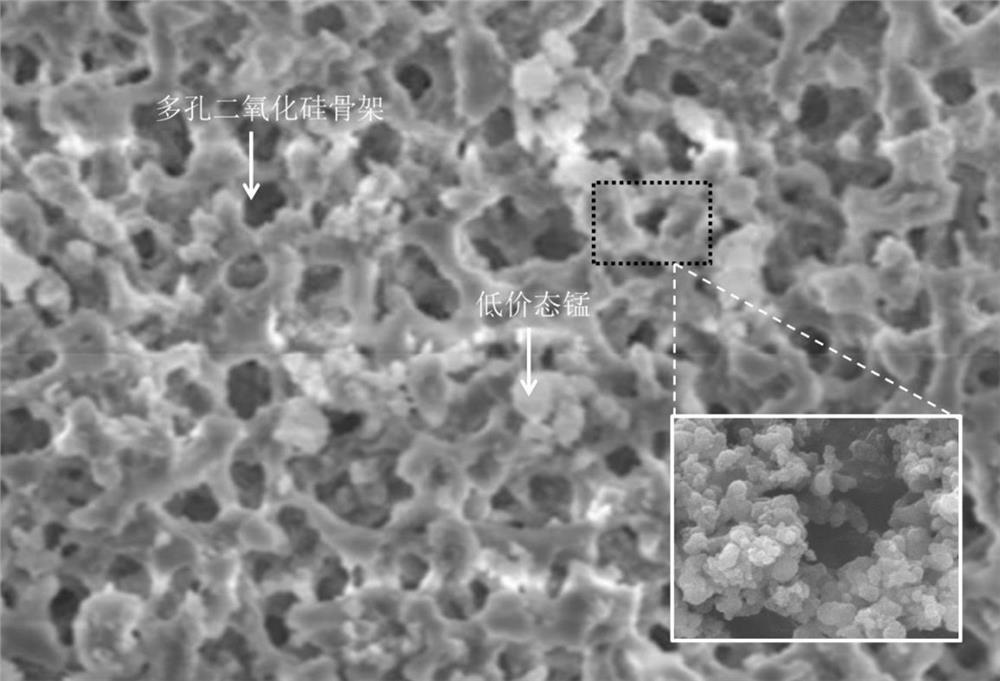

[0054] (3) Remove toluene in polyborosiloxane gel by means of supercritical drying. The medium of supercritical drying is carbon dioxide, the supercritical temperature is 32°C, and the supercritical pressure is 7.5MPa. Polyborosiloxane was heat-treated at 700°C for 6 hours under the protection of nitrogen, and the oxygen adsorbent was obtained by cooling down. The electron microscope photos are as follows: figure 1 shown.

Embodiment 2

[0056] A kind of preparation method of oxygen adsorbent, the preparation method of described oxygen adsorbent is as follows:

[0057] (1) Disperse 4.05g of manganese oxide powder into 100ml of toluene to form a dispersion;

[0058] (2) Dissolve 15g of borosiloxane containing silicon hydrogen structure and 12g of borosiloxane with vinyl structure in the above dispersion liquid respectively, add 13.5mg of chloroplatinic acid to it, stir and react at 85°C for 3h, Obtain polyborosiloxane gel coated with manganese oxide;

[0059] (3) Remove toluene in polyborosiloxane gel by means of supercritical drying. The medium of supercritical drying is carbon dioxide, the supercritical temperature is 32°C, and the supercritical pressure is 7.5MPa. The polyborosiloxane was heat-treated at 800° C. for 3 hours under the protection of nitrogen, and the temperature was lowered to obtain an oxygen adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com