Current collector, lithium ion battery and preparation method thereof

A lithium-ion battery and current collector technology, applied in the field of lithium-ion batteries, can solve problems such as difficulty in resisting deformation of battery pole pieces, inability to apply lithium-ion batteries, and difficulty in resisting electrolyte erosion, etc., to achieve enhanced adhesion and enhanced stability , the effect of ensuring integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

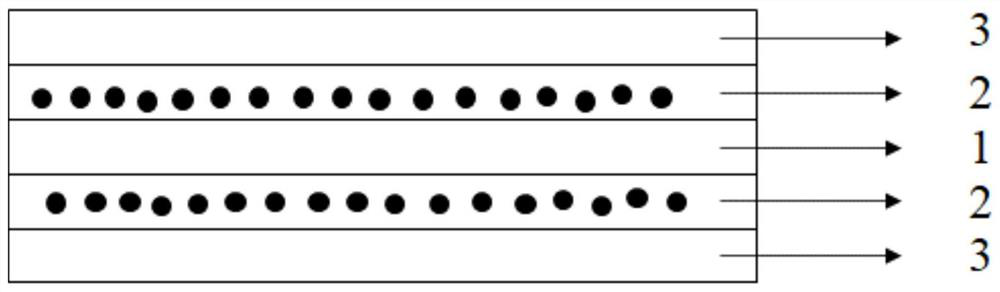

[0044] The preparation method of the current collector provided in Example 1 of the present invention comprises the following steps:

[0045] (1) First, the surface of the commercial polymer membrane is cleaned to remove impurities on the surface.

[0046] (2) Plasma treatment is performed on the dried film substrate to activate both the upper and lower surfaces, which is beneficial to increase its binding force with the reinforcing layer.

[0047] (3) The film substrate layer is placed in a primer coating machine to prepare an adhesive reinforcement layer, and the adhesive used is a composite coating of CMC and silicon oxide. Wherein, the content of silicon oxide is 10%, and the solid content of silicon oxide and CMC is 50%.

[0048] (4) Place the thin film reinforced by the binder on the substrate of magnetron sputtering to prepare 800nm metal aluminum to obtain the required current collector.

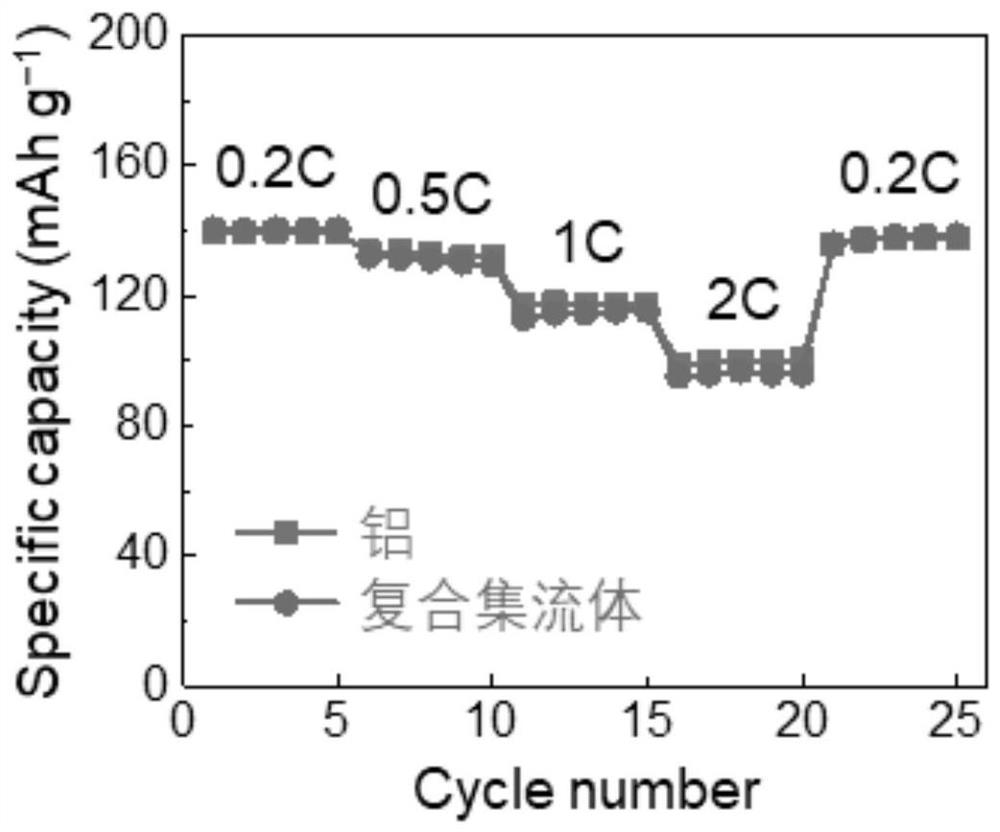

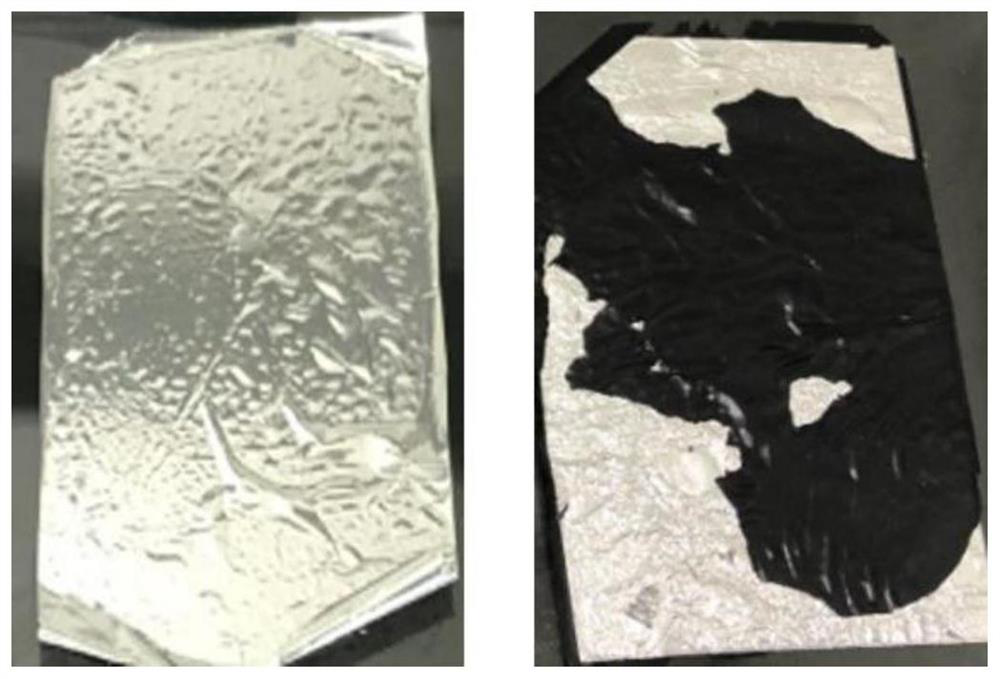

[0049] (5) The commercialized NCM523 is used as an active material, a binder...

Embodiment 2

[0052] The preparation method of the current collector provided in Example 2 of the present invention comprises the following steps:

[0053] (1) First, the surface of the commercial polymer membrane is cleaned to remove impurities on the surface.

[0054] (2) Plasma treatment is performed on the dried film substrate for use, so that both the upper and lower surfaces are activated, which is beneficial to increase its binding force with the reinforcing layer.

[0055] (3) Place the film substrate layer in a primer coater to prepare an adhesive reinforcement layer, and the adhesive used is a composite coating of SBR and silicon oxide. Among them, the content of alumina is 10%, and the solid content of alumina and SBR is 50%.

[0056] (4) Place the thin film base material strengthened by the binder on the magnetron sputtering substrate to prepare 800nm metal aluminum to obtain the required current collector.

[0057] (5) The commercialized NCM523 is used as an active material...

Embodiment 3

[0059] The preparation method of the current collector provided in Example 3 of the present invention comprises the following steps:

[0060] (1) First, the surface of the commercial polymer membrane is cleaned to remove impurities on the surface.

[0061] (2) Plasma treatment is performed on the dried film substrate for use, so that both the upper and lower surfaces are activated, which is beneficial to increase its binding force with the reinforcing layer.

[0062] (3) The film substrate layer is placed in a primer coater to prepare an adhesive reinforcement layer, and the adhesive used is a composite coating of PAA and silicon oxide. Wherein, the content of titanium oxide is 10%, and the solid content of titanium oxide and PAA is 50%.

[0063] (4) Place the thin film base material strengthened by the binder on the magnetron sputtering substrate to prepare 800nm metal aluminum to obtain the required current collector.

[0064] (5) The commercialized NCM523 is used as an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com