Polyamide composite membrane high-flux modification method based on small molecular alcohol free radicals

A technology of small molecular alcohol and polyamide, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. The effect of improving adsorption and dissolution rate, increasing membrane water flux, and uniform hydrophilic type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

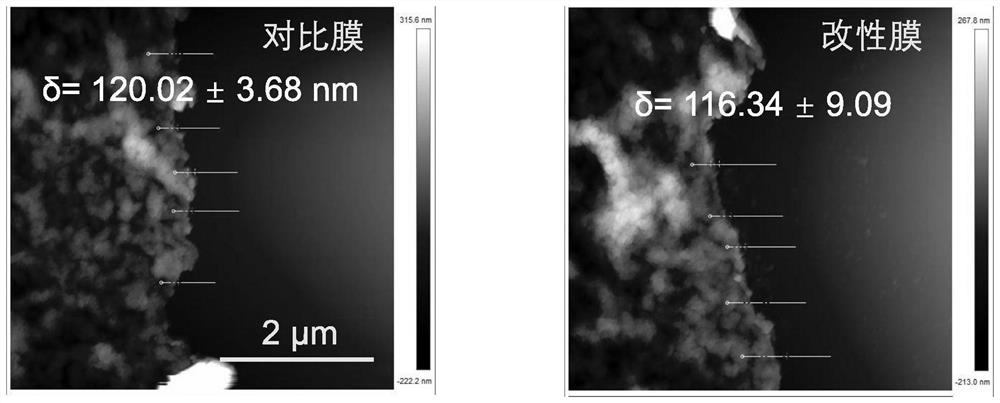

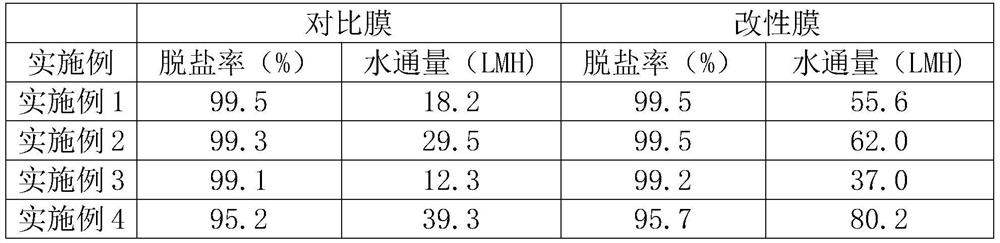

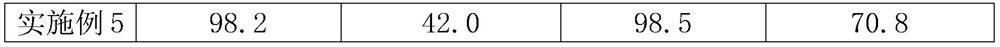

[0025] Select the polyamide composite reverse osmosis membrane from Dow Filmtech Company in the United States, immerse it in the modification solution, and modify it at 40°C for 1h. The modification solution includes: 200 mg / L ammonium persulfate, 50% (v / v) ethanol, 50% (v / v) water. After the modified solution was preheated to 40°C, the polyamide composite membrane was added, and the membrane was taken out after 1 hour of modification, and the modified membrane was fully cleaned with water before testing.

[0026] The membrane that was not treated with the modifying solution was the comparative membrane.

[0027] The test conditions are: the operating pressure is 14bar, the flow rate is 3LPM, the modified membrane and the comparison membrane are pre-pressed with ultra-pure water for 6 hours at 25°C to stabilize the membrane performance, and the operating pressure is adjusted to 10bar to measure the water flow of the modified membrane and the comparison membrane. quantity. Pr...

Embodiment 2

[0029] Select the polyamide composite reverse osmosis membrane from Zhongke Ruiyang Membrane Technology (Beijing) Co., Ltd., immerse it in the modification solution, and modify it at 50°C for 0.5h. The modification solution includes: 500 mg / L potassium hydrogen persulfate compound salt, 20% (v / v) n-propanol, and 80% (v / v) water. After the modified solution was preheated to 50°C, the polyamide composite membrane was added, and the membrane was taken out after 0.5h of modification, and the modified membrane was fully cleaned with water before testing.

[0030] The membrane that was not treated with the modifying solution was the comparative membrane.

[0031] The test conditions are: the operating pressure is 14bar, the flow rate is 3LPM, the modified membrane and the comparison membrane are pre-pressed with ultra-pure water for 6 hours at 25°C to stabilize the membrane performance, and the operating pressure is adjusted to 10bar to measure the water flow of the modified membran...

Embodiment 3

[0033] The polyamide composite reverse osmosis membrane independently developed by the inventor was selected, immersed in the modification solution, and modified at 60° C. for 2 hours. The modification solution includes: 200 mg / L sodium persulfate, 200 mg / L potassium hydrogen persulfate compound salt, 40% (v / v) n-butanol, 60% (v / v) water. After the modified solution was preheated to 60°C, the polyamide composite membrane was added, the membrane was taken out after 2 hours of modification, and the modified membrane was fully cleaned with water before testing.

[0034] The membrane that was not treated with the modifying solution was the comparative membrane.

[0035] The test conditions are: the operating pressure is 14bar, the flow rate is 3LPM, the modified membrane and the comparison membrane are pre-pressed with ultra-pure water for 6 hours at 25°C to stabilize the membrane performance, and the operating pressure is adjusted to 10bar to measure the water flow of the modifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com