High-thermal-conductivity graphene heat dissipation film and preparation method thereof

A high thermal conductivity graphite and ene heat dissipation film technology, applied in graphene, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high viscosity of dispersion liquid or slurry, poor product appearance, small solid content, etc., and achieve easy dispersion And, enhance the effect of solid content, high solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

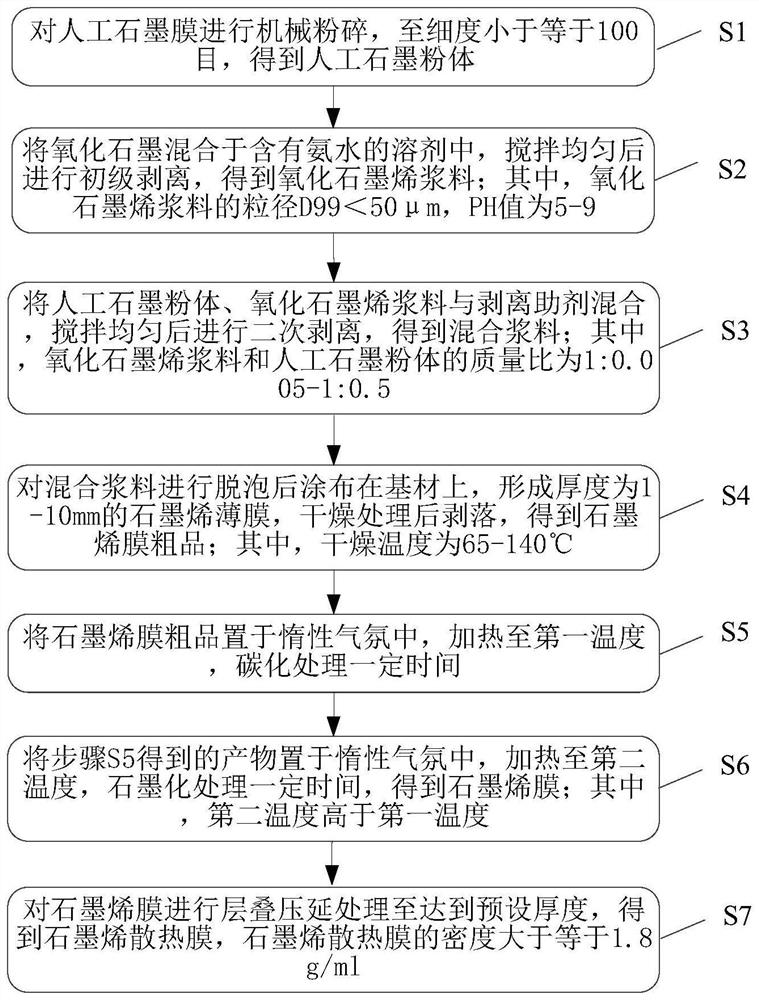

Method used

Image

Examples

Embodiment 1

[0067] This embodiment discloses a method for preparing a high thermal conductivity graphene heat dissipation film. The preparation method includes the following steps:

[0068] (1) Mechanically pulverize the leftovers of the artificial graphite film until the fineness is less than or equal to 100 mesh, and obtain the artificial graphite powder.

[0069] (2) Mix graphite oxide with an aqueous solution containing ammonia water, stir evenly, and then add it to a peeling machine for primary peeling until the particle size of the slurry is D99<50 μm to obtain a graphene oxide slurry. Wherein, the pH value of the slurry is 5-9, the mass percentage of graphite oxide is 5 wt%, the mass percentage of ammonia water is 0.2 wt%, and the concentration of ammonia water is 25%.

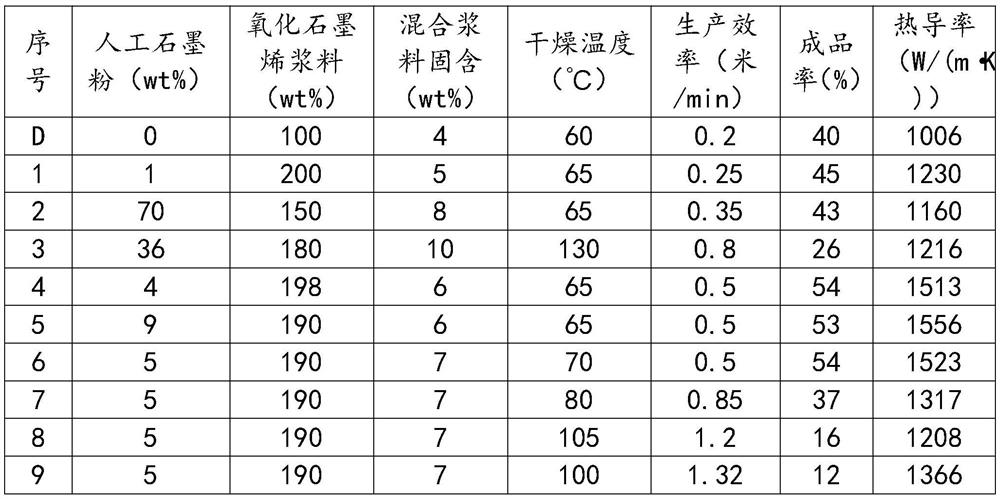

[0070] (3) Take by weighing 200 parts by weight of graphene oxide slurry, 1 part by weight of artificial graphite powder and sodium dodecylbenzene sulfonate, mix and stir and then join in the peeling machine for se...

Embodiment 2

[0076] This embodiment discloses a method for preparing a high thermal conductivity graphene heat dissipation film. The preparation method includes the following steps:

[0077] (1) Mechanically pulverize the leftovers of the artificial graphite film until the particle size of the slurry is less than or equal to 200 mesh, and obtain the artificial graphite powder.

[0078] (2) Mix graphite oxide with an ethanol solution containing ammonia water, stir evenly, and then add it to a peeling machine for primary peeling until the particle size of the slurry is D99<40 μm, and until the particle size of the slurry is D99<35 μm, the graphene oxide slurry is obtained . Wherein, the pH value is 5-9, the mass percentage of graphite oxide is 4 wt%, the mass percentage of ammonia water is 0.4 wt%, and the concentration of ammonia water is 25%.

[0079] (3) Weighing 150 parts by weight of graphene oxide slurry, 70 parts by weight of artificial graphite powder and glucose, mixed and stirred ...

Embodiment 3

[0085] This embodiment discloses a method for preparing a high thermal conductivity graphene heat dissipation film. The preparation method includes the following steps:

[0086] (1) Mechanically pulverize the leftovers of the artificial graphite film until the particle size of the slurry is less than or equal to 400 mesh, and obtain the artificial graphite powder.

[0087] (2) Mix graphite oxide with an ethanol solution containing ammonia water, stir evenly, and then add it to a peeling machine for primary peeling until the particle size of the slurry is D99<40 μm to obtain a graphene oxide slurry. Wherein, the pH value of the slurry is 5-9, the mass percentage of graphite oxide is 5 wt%, the mass percentage of ammonia water is 0.6 wt%, and the concentration of ammonia water is 30%.

[0088] (3) Weigh 180 parts by weight of graphene oxide slurry, 36 parts by weight of artificial graphite powder and tannic acid, mix and stir evenly, then add to the peeling machine for secondary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com