Bacteriostatic water-based paint for furniture and production equipment thereof

A technology for water-based coatings and production equipment, applied in the direction of anti-fouling/underwater coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems affecting the service life of water-based coatings, aging and discoloration of water-based coatings, affecting application and sensory perception, etc. , to achieve the effect of improving anti-aging performance, good decoration and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An antibacterial water-based coating for furniture, which is composed of the following raw materials in parts by weight: 50 parts of water-based polyurethane resin, 8 parts of compound antibacterial agent, 14 parts of ECO-3378 wetting and dispersing agent, 7 parts of nano-sized titanium dioxide, 11 parts of nano-sized Silica, 3 parts of synergistic antibacterial agent, 0.8 part of DM-638 thickener, 0.5 part of KMT-700 leveling agent, 0.12 part of butanediol isooctyl ether film-forming aid, 1.4 parts of cellulose hydroxyethyl ether and 35 parts water.

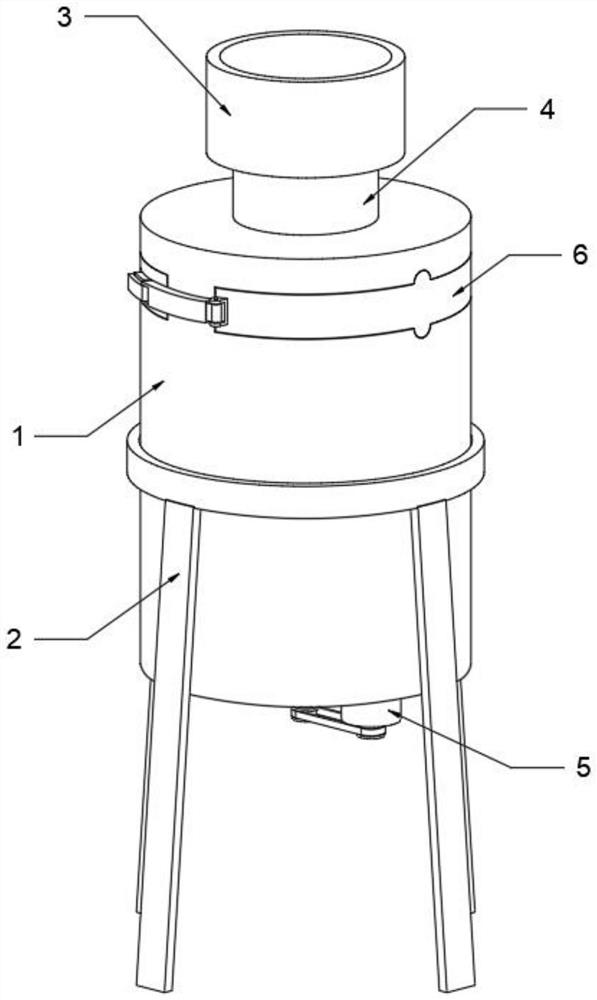

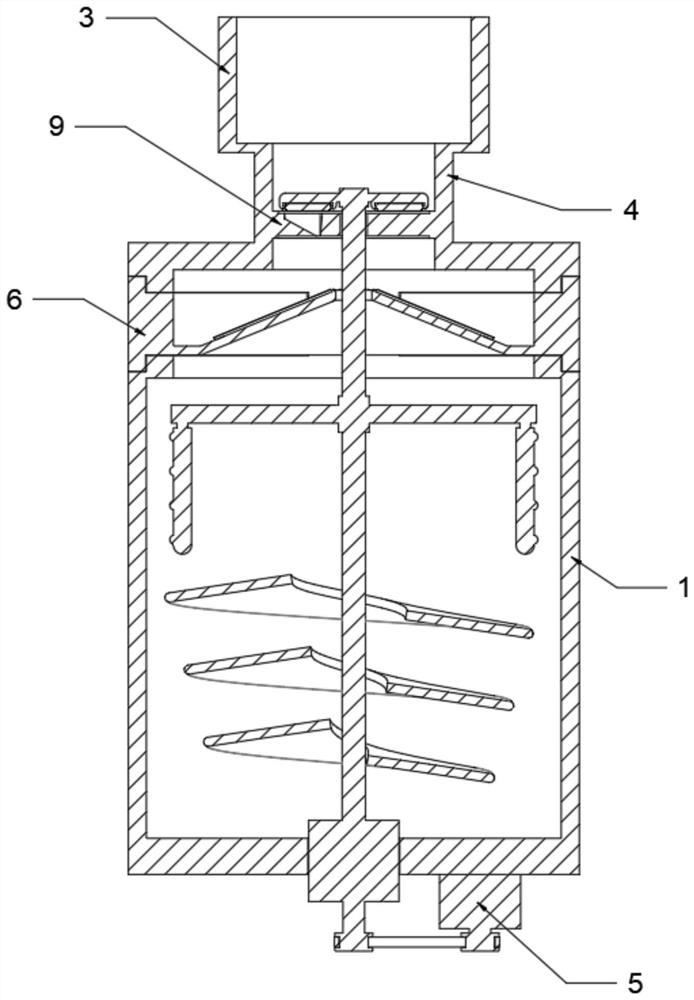

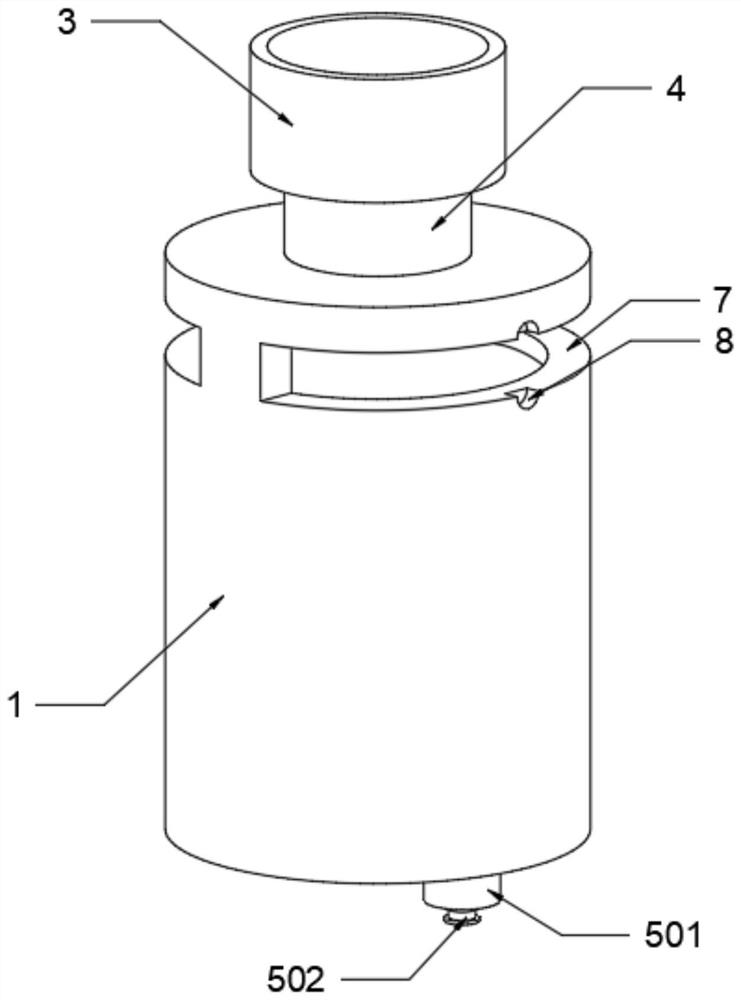

[0048] The using method of the antibacterial water-based coating production equipment for furniture provided by the present invention is:

[0049] Put the above raw materials into the feeding hopper one by one, start the power supply of the servo motor, which drives the stirring assembly through the outer driving wheel and the transmission belt, and the cleaning brush in the upper bracket is located above the combing disc...

Embodiment 2

[0059] Compared with Example 1, the specific proportioning of the antibacterial water-based paint raw materials provided by the two is different, wherein the specific proportioning of each raw material in the present embodiment is:

[0060] 45 parts of water-based polyurethane resin, 6 parts of compound antibacterial agent, 5 parts of ECO-2100 wetting and dispersing agent, 5 parts of nano-scale titanium dioxide, 10 parts of nano-scale silicon dioxide, 2.5 parts of synergistic antibacterial agent, 0.6 part of DM- SD1084 thickener, 0.4 part of KMT-310 leveling agent, 0.8 part of tetraethylene glycol film-forming aid, 0.7 part of cellulose hydroxyethyl ether and 30 parts of water.

Embodiment 3

[0062] Compared with Example 1, the specific proportioning of the antibacterial water-based paint raw materials provided by the two is different, wherein the specific proportioning of each raw material in the present embodiment is:

[0063] 43 parts of water-based polyurethane resin, 5 parts of compound antibacterial agent, 0.5 part of EV-635 wetting and dispersing agent, 2 parts of nano-scale titanium dioxide, 6 parts of nano-scale silicon dioxide, 2 parts of synergistic antibacterial agent, 0.5 part of DM- 121 thickener, 0.2 part of KMT-5514 leveling agent, 0.5 part of ethylene glycol film-forming aid, 0.5 part of cellulose hydroxyethyl ether and 25 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com