2-2 type piezoelectric composite material and preparation method and application thereof

A piezoelectric composite material and piezoelectric material technology, applied in the field of 2-2 piezoelectric composite materials and its preparation, can solve the problem of small piezoelectric coefficient and electromechanical coupling coefficient, unsuitable for transmitting transducers, density and acoustic impedance Advanced problems, to achieve high voltage coefficient, reduce crystal fracture rate, improve the effect of working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

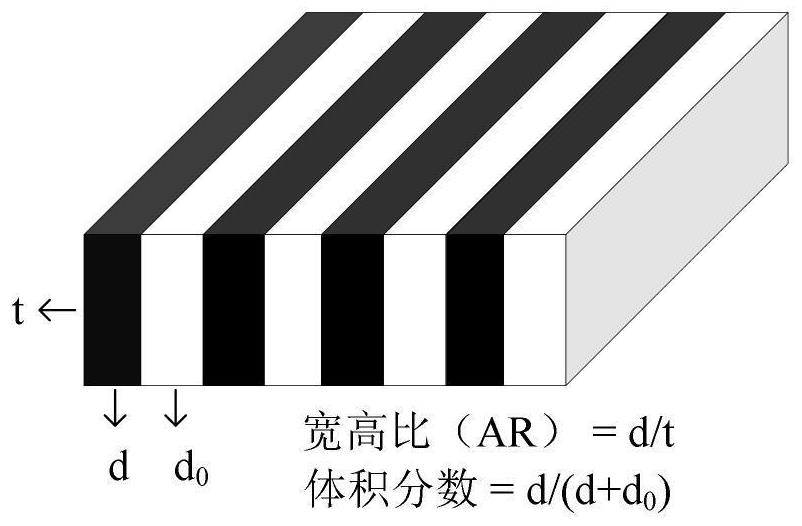

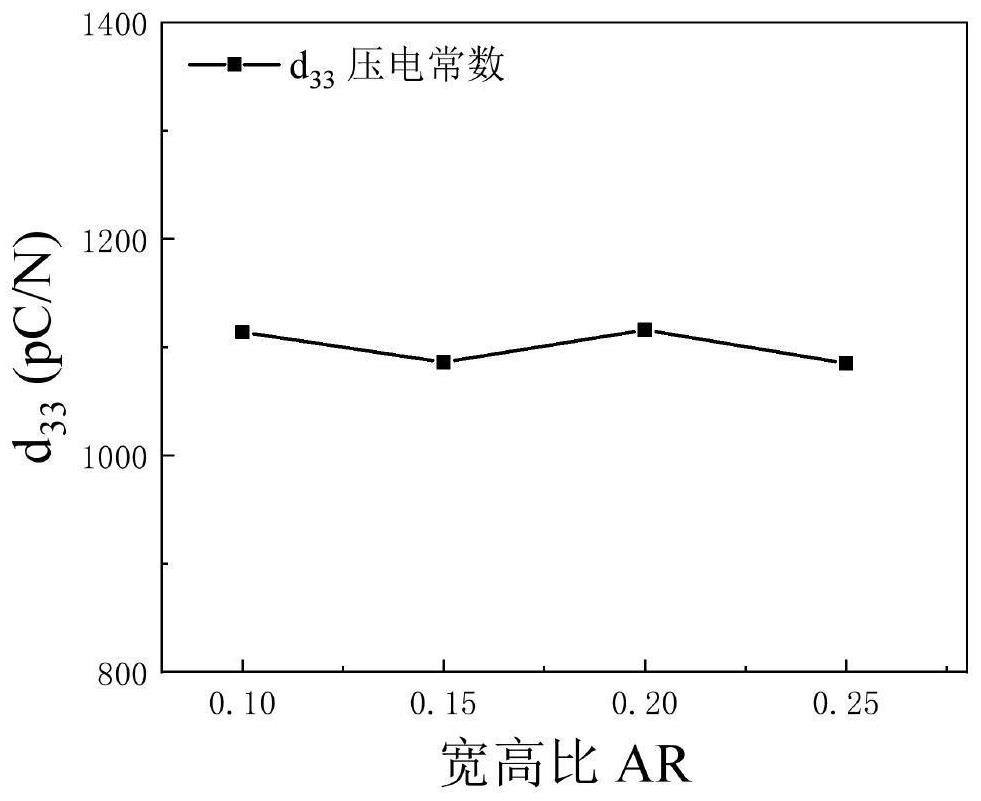

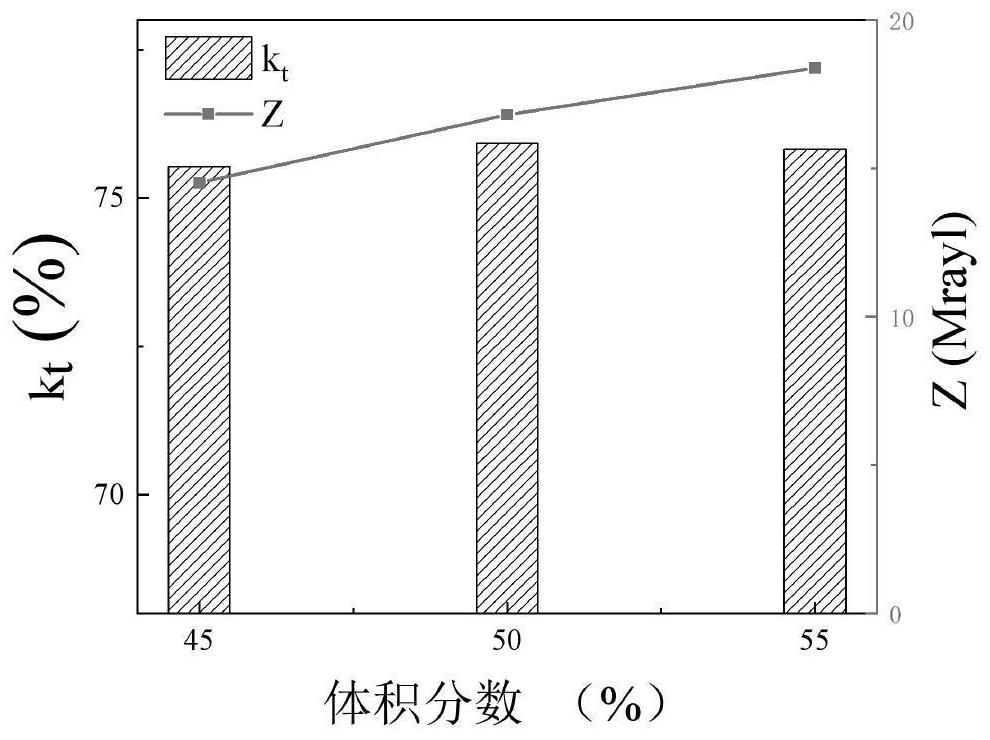

[0037] Such as figure 1 As shown, a 2-2 type piezoelectric composite material is a piezoelectric single crystal and epoxy resin composite material, which is composed of PIMNT (ie PIN-PMN-PT, lead indium niobate-lead magnesium niobate-lead titanate ) Piezoelectric single crystal is cut and poured with epoxy resin, cured, polished and shaped. Among them, the PIMNT piezoelectric single crystal is polarized in the [001] direction, and its volume fraction is one of 45%, 50%, and 55%, and preferably 50%; its aspect ratio is 0.15, 0.17, 0.2, and 0.21. One of, and preferably 0.2. The epoxy resin is EPO-TEK 301, which has high flexibility, low density, curing at room temperature, and good acoustic matching performance.

[0038] The preparation method of this composite material is as follows:

[0039] (1) Cutting PIMNT piezoelectric single crystal: using a precision dicing machine, after sample fixing, microscopic knife setting, determination of cutting parameters, cleaning and dryin...

Embodiment 2

[0046] The difference between this embodiment and embodiment 1 is:

[0047] The aspect ratio of the piezoelectric single crystal in the composite material obtained in step (6) is 0.15, and the volume fraction is 45%.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is:

[0050] The aspect ratio of the piezoelectric single crystal in the composite material obtained in step (6) is 0.15, and the volume fraction is 45%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Piezoelectric constant | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com