Synthesis method of M (at) SSZ-13 (at) NanoBeta with core-shell structure

A core-shell structure, in-situ synthesis technology, applied in chemical instruments and methods, carbon compound catalysts, catalysts including molecular sieves, etc., can solve problems such as inability to prevent precious metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

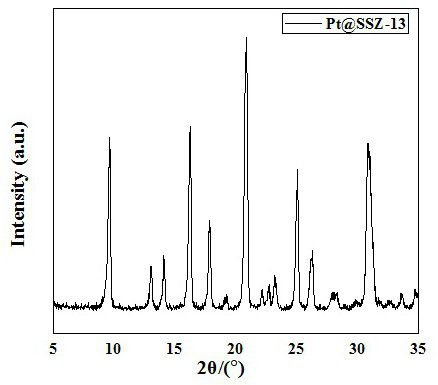

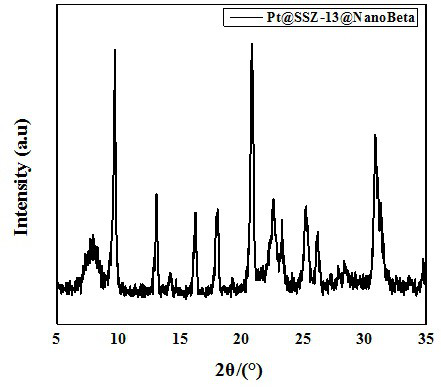

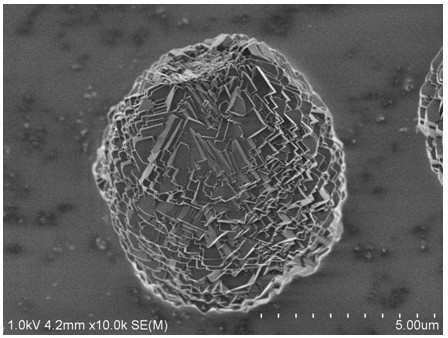

[0049] A preparation method of Pt@SSZ-13@NanoBeta core-shell structure, the specific operation is as follows: Weigh 0.66g sodium hydroxide (NaOH), dissolve it in 7mL distilled water, add dropwise 660µl 0.02g / mL chloroplatinic acid solution (H2PtCl6 •6H2O (Pt≥37.5%)), add 75µl 3-mercaptopropyltrimethoxysilane (TMSH) dropwise, stir for 0.5h, add 6.5g N,N,N-trimethyl-1-adamantyl hydrogen dropwise Ammonium oxide ((TMAdaOH≥25%), stir evenly, add 0.62g sodium aluminate (NaAlO2), stir for 0.5h, then add dropwise 7.5g silica sol (SiO2=40%), stir for 2h, form initial gel, mol The proportioning ratio is SiO2:Al2O3:Pt:TMSH:TMAdaOH:Na2O:H2O=20:1:0.01:0.15:3:4.7:364.

[0050] The above initial gel was put into a hydrothermal reaction kettle, heated to 160°C for hydrothermal crystallization reaction for 96 hours, the product was filtered, washed, dried, and calcined at 550°C for 6 hours to obtain the product Pt@SSZ-13 molecular sieve.

Embodiment 2

[0058] A preparation method of Pt@SSZ-13@NanoBeta core-shell structure, the specific operation is as follows: Weigh 0.8g sodium hydroxide, dissolve it in 7mL distilled water, add dropwise 1255µl 0.02g / mLH2PtCl6•6H2O (Pt≥37.5%), Add 141µl 3-mercaptopropyltrimethoxysilane dropwise, stir for 0.5h, add dropwise 5g N,N,N-trimethyl-1-adamantyl ammonium hydroxide ((TMAdaOH≥25%), stir well, add 0.3 g sodium aluminate, stirred for 0.5h, then added dropwise 7.5g of 40% silica sol, stirred for 2h to form an initial gel, and the molar ratio was SiO2: Al2O3: Pt: TMSH: TMAdaOH: Na2O: H2O=40:1: 0.04: 0.6: 5: 10: 706. Put the above initial gel into a hydrothermal reaction kettle, heat up to 160°C for hydrothermal crystallization reaction for 96 hours, filter the product, wash, dry, and roast at 550°C for 6 hours to obtain the product Pt@ SSZ-13 molecular sieve. Figure 21 is the EDSmapping layered diagram of Pt@SSZ-13 molecular sieve, Figure 22 It is the EDS mapping Pt distribution diagram...

Embodiment 3

[0063] A preparation method of Pd@SSZ-13@NanoBeta core-shell structure, the specific operation is as follows: Weigh 0.66g sodium hydroxide, dissolve it in 12mL distilled water, add 21 µl 0.1g / mL PdCl2 (Pd≥59%) dropwise, Add 40µl 3-mercaptopropyltrimethoxysilane dropwise, stir for 0.5h, add dropwise 6.5g N,N,N-trimethyl-1-adamantyl ammonium hydroxide ((TMAdaOH≥25%), stir evenly, Add 0.6g of sodium aluminate, stir for 0.5h, then add 7.5g of 40% silica sol dropwise, stir for 2h to form an initial gel. The molar ratio is SiO2: Al2O3: Pd: TMSH: TMAdaOH: Na2O: H2O=20: 1: 0.004: 0.08: 3: 4.7: 364. Put the above initial gel into a hydrothermal reaction kettle, heat up to 160°C for hydrothermal crystallization reaction for 96 hours, filter, wash and dry the product, and roast at 550°C for 6 hours to obtain the product Pd@SSZ-13 molecular sieve.

[0064] Weigh 0.26g of sodium hydroxide, dissolve it in 4.3mL of distilled water, add dropwise 25.8g of tetraethylammonium hydroxide, stir ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com