Efficient electro-deposition preparation method and application of metal organic framework film

A metal-organic framework, electrodeposition technology, applied in the direction of electrolytic organic material coating, hybrid capacitor electrodes, etc., can solve problems such as substrate limitation, and achieve the effect of improving poor conductivity, high area specific capacitance, preventing agglomeration and structural collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

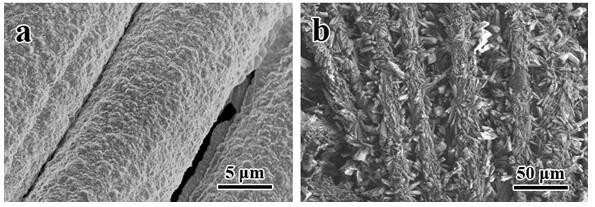

[0042] A method for preparing a Co metal layer modified carbon cloth substrate electrodeposited Co-MOF film, comprising the following steps:

[0043] (1) Substrate pretreatment: Soak the carbon cloth substrate (1 cm × 2 cm) in acetone, deionized water and ethanol for 15 min and ultrasonically clean it, then H 2 SO 4 / HNO 3 (volume ratio 3:1) activated at 70 °C for 3 h, washed and dried for later use.

[0044] (2) Highly active metal layer modification: a two-electrode system was adopted, with treated carbon cloth as the working electrode (working area 1 cm×1 cm), platinum sheet as the counter electrode, cobalt sulfate (0.1 mol / L), The aqueous solution of sodium sulfate (0.2 mol / L) and boric acid (0.2 mol / L) is the electrolyte, the volume of the electrolyte is 50 mL, and the pH is 2.4. at −0.1 A / cm 2 Electrodeposition was performed at a constant current with a reaction time of 500 s, and a Co metal modification layer was formed on the surface of the carbon cloth. After the ...

Embodiment 2

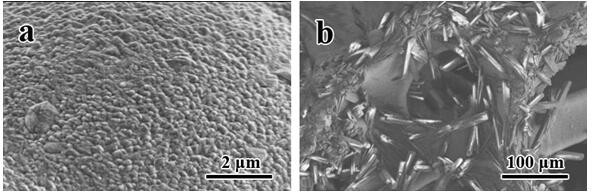

[0047] A method for preparing a Co metal layer modified nickel foam substrate electrodeposited MOF film, wherein the highly active metal layer modification and the cathodic electrodeposition steps of the MOF film are the same as in Example 1, the difference lies in the selection and pretreatment of the substrate: this The example uses nickel foam as the substrate, and before use, it is ultrasonically cleaned in acetone, 1 mol / L hydrochloric acid, deionized water and ethanol for 15 minutes, and dried for use.

Embodiment 3

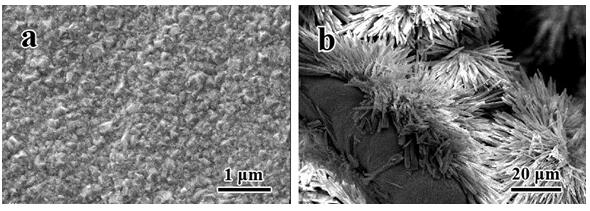

[0049] A kind of preparation method of Ni metal layer modification nickel foam substrate electrodeposited MOF film, comprises the following steps:

[0050] (1) Substrate pretreatment: the same as the substrate pretreatment steps in Example 2.

[0051] (2) Highly active metal layer modification: a two-electrode system was adopted, with the treated nickel foam as the working electrode (working area 1 cm×1 cm), platinum sheet as the counter electrode, and 50 mL of nickel chloride (0.1 mol / L ), an aqueous solution of potassium chloride (0.2 mol / L) and boric acid (0.2 mol / L) is the electrolyte. at −0.1 A / cm 2 Electrodeposition was performed at a constant current with a reaction time of 600s, and a metal Ni modification layer was deposited on the nickel foam substrate. After the deposition, it was cleaned with deionized water and ethanol.

[0052] (3) Cathodic electrodeposition of MOF film: The Ni metal layer modified nickel foam obtained in step (2) was used as the working electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com