Preparation method of antibacterial and deodorant regenerated cellulose fiber

A technology of regenerated cellulose and cellulose, applied in the field of fiber, can solve the problem of no antibacterial and deodorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

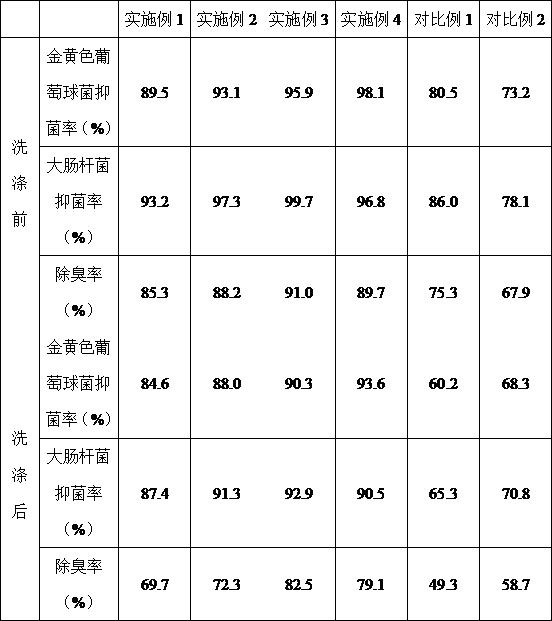

Examples

Embodiment 1

[0026] (1) Grind mugwort, extract it ultrasonically at 60°C, the power of ultrasonic extraction is 720W, the frequency is 40KHz, after extraction for 1 hour, perform purification, after purification, dry to obtain plant functional components;

[0027] (2) Stir and mix bamboo cellulose, sodium periodate, and sodium acetate buffer solution with a mass ratio of 5:8:25, and react at 20°C for 4 hours to obtain a dialdehyde cellulose suspension;

[0028] (3) Mix the plant functional components with a mass ratio of 5:80 and the dialdehyde cellulose suspension, and react at 40°C for 2 hours. After the reaction, a polyphenol-cellulose composite material is obtained;

[0029] (4) Mix the polyphenol-cellulose composite material with a mass ratio of 3:97 and a mixed solvent to obtain a functional cellulose solution, and add a thickener bentonite and a coagulation bath to the functional cellulose solution, in which the polyphenol-cellulose The mass ratio of the composite material, bentonit...

Embodiment 2

[0031] (1) Grind the green tea and extract it ultrasonically at 150°C. The power of the ultrasonic extraction is 720W and the frequency is 40KHz. After extraction for 2 hours, it is purified. After purification, it is dried to obtain plant functional components;

[0032] (2) Stir and mix cotton cellulose, sodium periodate, and sodium acetate buffer solution with a mass ratio of 5:9:30, and undergo a modification reaction at 30°C for 5 hours to obtain a dialdehyde cellulose suspension;

[0033] (3) Mix the plant functional components with a mass ratio of 5:85 and the dialdehyde cellulose suspension, and react at 40°C for 2 hours. After the reaction, a polyphenol-cellulose composite material is obtained;

[0034] (4) Mix the polyphenol-cellulose composite material with a mass ratio of 3:97 and a mixed solvent to obtain a functional cellulose solution, add a thickener lauryl alcohol and a coagulation bath to the functional cellulose solution, in which the polyphenol-cellulose The...

Embodiment 3

[0036] (1) Grind the kiwi fruit, extract it ultrasonically at 250°C, the power of the ultrasonic extraction is 720W, and the frequency is 40KHz. After extraction for 3 hours, it is purified and dried after purification to obtain plant functional components;

[0037] (2) Stir and mix cotton cellulose, sodium periodate, and sodium acetate buffer solution with a mass ratio of 5:10:32, and undergo a modification reaction at 35°C for 6 hours to obtain a dialdehyde cellulose suspension;

[0038] (3) Mix the plant functional components with a mass ratio of 5:90 and the dialdehyde cellulose suspension, and react at 80°C for 8 hours. After the reaction, a polyphenol-cellulose composite material is obtained;

[0039] (4) Mix the polyphenol-cellulose composite material with a mass ratio of 3:97 and a mixed solvent to obtain a functional cellulose solution, and add a thickener polyacrylate and a coagulation bath to the functional cellulose solution, in which the polyphenol- The mass ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com