Chemical anti-sagging exposed single-component polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and anti-sagging technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve problems such as flow, delay in construction period, waste of manpower and material resources, etc., and achieve dense coating, high strength, and increased storage time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Example 1 A chemical anti-sagging exposed type one-component polyurethane waterproof coating and its preparation method

[0061] The components and dosage (unit: parts by weight) of the chemical anti-sagging exposed type one-component polyurethane waterproof coating are shown in the following table.

[0062] Polyether diol 2000D 6 Polyether Triol 330N 24 Chlorinated paraffin 10 Chloromethyl hexadecanoate 2 carbon black 0.3 talcum powder 18 Heavy calcium 800 mesh 20 Antioxidant 1010 0.3 Light stabilizer tinuvin626 0.3 UV absorber tinuvin770 0.3 Phosphoric acid aqueous solution (85% mass fraction) 0.1 Calcium Oxide 2 Water remover TI 1 HMDI 6 Zinc isooctanoate 0.5 D80 alkane oil 8 4,4'-Diaminodiphenylmethane 0.3 Butyl acetate 0.9

[0063] Its preparation method is:

[0064] a. Add formula amount of polyether diol 2000D, polyether triol 330N, chlorinated para...

Embodiment 2

[0073] Example 2 A chemical anti-sagging exposed type one-component polyurethane waterproof coating and its preparation method

[0074] The components and dosage (unit: parts by weight) of the chemical anti-sagging exposed type one-component polyurethane waterproof coating are shown in the following table.

[0075] Polyether diol 2000D 6.4 Polyether Triol 330N 27.6 Tri-n-butyl citrate 3 Chloromethyl hexadecanoate 10 carbon black 0.3 Kaolin 800 mesh 15 Heavy calcium 800 mesh 18 Antioxidant T501 0.4 Light stabilizer tinuvin765 0.5 UV absorber tinuvin327 0.5 Phosphoric acid aqueous solution (85% mass fraction) 0.1 Calcium Oxide 2 Water remover TI 1 HMDI 6.8 bismuth organic acid 0.6 D80 alkane oil 6 4,4'-Diaminodiphenylmethane 0.34 Propylene glycol methyl ether acetate 1.46

[0076] Its preparation method is:

[0077] a. Add formula amount of polyether diol 2000D, po...

Embodiment 3

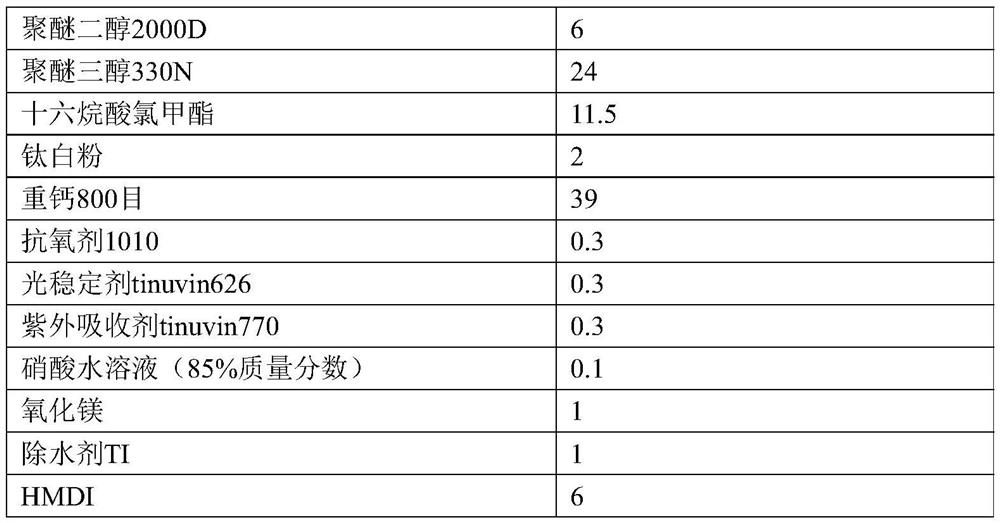

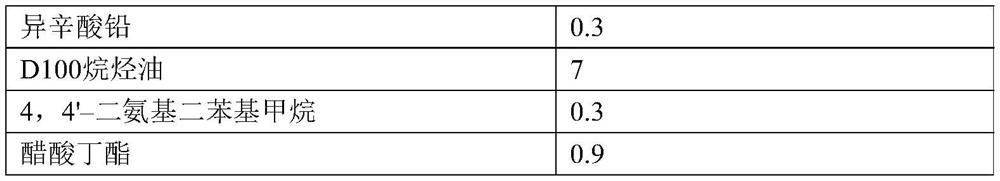

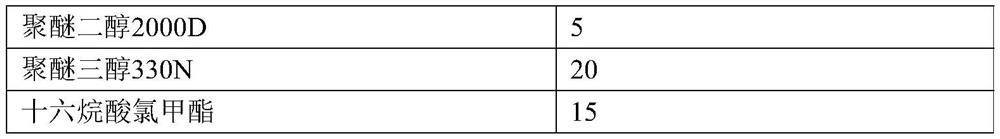

[0086] Example 3 A chemical anti-sagging exposed type one-component polyurethane waterproof coating and its preparation method

[0087] The components and dosage (unit: parts by weight) of the chemical anti-sagging exposed type one-component polyurethane waterproof coating are shown in the following table.

[0088]

[0089]

[0090] Its preparation method is:

[0091] a. Add the formula amount of polyether diol 2000D, polyether triol 330N, and chloromethyl hexadecanoate to the reaction vessel and raise the temperature to 80°C, add the formula amount of titanium dioxide, heavy calcium 800 mesh, and antioxidant 1010 , Light stabilizer tinuvin626, UV absorber tinuvin770, heat up to 100°C-120°C, dehydrate with nitrogen for 4 hours under the condition of vacuum below -0.095MPa;

[0092] B. add the nitric acid aqueous solution of formula quantity;

[0093] c. Lower the temperature to 70°C, add the prescribed amount of magnesium oxide under high-speed stirring, and remove wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com