Preparation method and application of environment-friendly tilapia mossambica feed

A tilapia and feed technology, which is applied in the field of feed, can solve the problems of affecting the feeding effect of tilapia feed, the decline of tilapia resistance, and the increase of water body nutrition, so as to meet the needs of environmental protection breeding, improve feed intake, The effect of reducing the content of nitrogen and phosphorus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

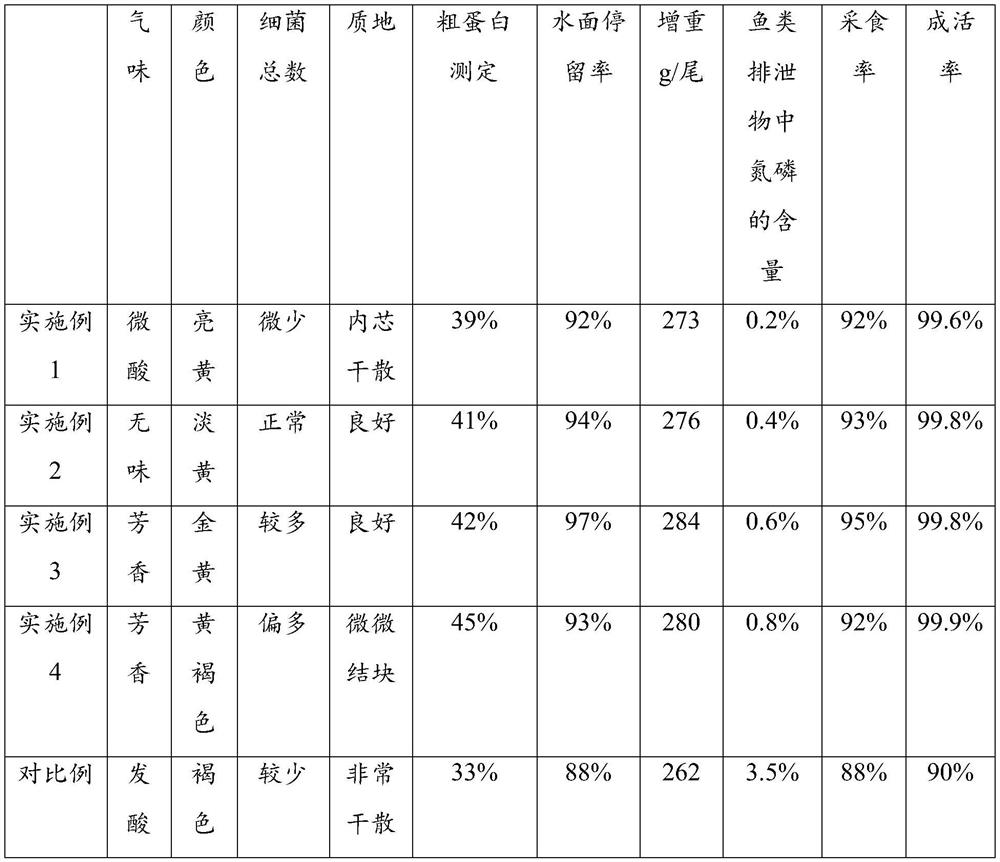

Examples

Embodiment 1

[0035] The method for the production of environment-friendly tilapia feed of the present embodiment may further comprise the steps:

[0036] S1. Lactobacillus, bacillus, saccharomycete and photosynthetic bacteria are inoculated (inoculum size is 3%) to the slant medium (0.5g beef extract, 0.5g peptone, 0.2g agar, 0.3g yeast powder and 1.2 ml distilled water) to obtain activated slant bacterial liquid, and then inoculated into liquid medium (0.5g glucose, 0.5g peptone and 1.2ml distilled water), and carried out anaerobic culture at 25-30°C for 15-20h to obtain source bacterial liquid;

[0037] S2. Plant the source bacteria solution into the fermentation medium (0.5g molasses, 0.5g glucose, 0.5g peptone and 1.2ml distilled water), and cultivate and co-exist at 27°C for 18h to obtain the strain infiltration solution;

[0038] S3. Add 1.5g of yellow corn, 0.5g of bran, 0.5g of wheat flour, 0.3g of rapeseed meal, 1.5g of distiller's grains, 0.5g of soybean meal and 0.7g of shrimp ...

Embodiment 2

[0041] The method for the production of environment-friendly tilapia feed of the present embodiment may further comprise the steps:

[0042] S1. Lactobacillus, bacillus, saccharomycete and photosynthetic bacteria are inoculated (inoculum size is 4%) to the slant medium (0.5g beef extract, 0.5g peptone, 0.2g agar, 0.3g yeast powder and 1.2 ml distilled water) to obtain activated slant bacteria liquid, then inoculated into liquid culture medium (0.5g glucose, 0.5g peptone and 1.2ml distilled water), and carried out anaerobic culture at 27°C for 18h to obtain the source bacteria with a pH of 3.7 liquid;

[0043] S2. Plant the source bacteria solution into the fermentation medium (0.5g molasses, 0.5g glucose, 0.5g peptone and 1.2ml distilled water), and cultivate and co-exist at 27°C for 18h to obtain the strain infiltration solution;

[0044]S3. Add 1.5g of yellow corn, 0.5g of bran, 0.5g of wheat flour, 0.3g of rapeseed meal, 1.5g of distiller's grains, 0.5g of soybean meal and...

Embodiment 3

[0047] The method for the production of environment-friendly tilapia feed of the present embodiment may further comprise the steps:

[0048] S1. Lactobacillus, bacillus, saccharomycete and photosynthetic bacteria are inoculated (inoculum size is 5%) to the slant medium (0.5g beef extract, 0.5g peptone, 0.2g agar, 0.3g yeast powder and 1.2 ml distilled water) to obtain activated slant bacteria liquid, then inoculated into liquid medium (0.5g glucose, 0.5g peptone and 1.2ml distilled water), and carried out anaerobic culture at 25-30°C for 15-20h to obtain pH It is the source bacterial liquid of 3.9;

[0049] S2. Plant the source bacteria solution into the fermentation medium (0.5g molasses, 0.5g glucose, 0.5g peptone and 1.2ml distilled water), and cultivate and co-exist at 27°C for 18h to obtain the strain infiltration solution;

[0050] S3. Add 1.5g of yellow corn, 0.5g of bran, 0.5g of wheat flour, 0.3g of rapeseed meal, 1.5g of distiller's grains, 0.5g of soybean meal and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com