Method for preparing aluminum alloy super-hydrophobic surface through laser peening

A super-hydrophobic surface, laser shot peening technology, applied in the fields of laser processing and material science, can solve the problems of reduced mechanical properties, low mechanical strength and poor stability of aviation aluminum alloy matrix materials, and achieves fine structure and grain refinement and efficient strengthening. , the effect of improving fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] S01: The 2024-T351 aluminum alloy plate is made into a 15mm×15mm×2mm square workpiece by wire cutting. Then use 400#, 800#, 1000#, 1500# and 2000# sandpaper to smooth the surface of the workpiece to be treated and polish it to a mirror surface, and finally put the surface polished workpiece into an alcohol solution for ultrasonic cleaning, so that there is no excess impurities on the surface of the material .

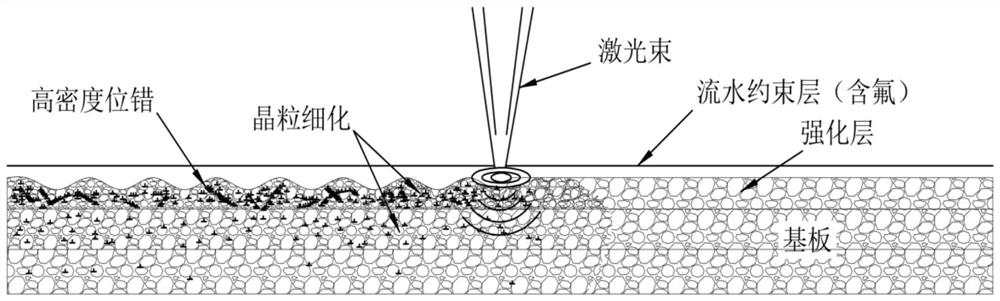

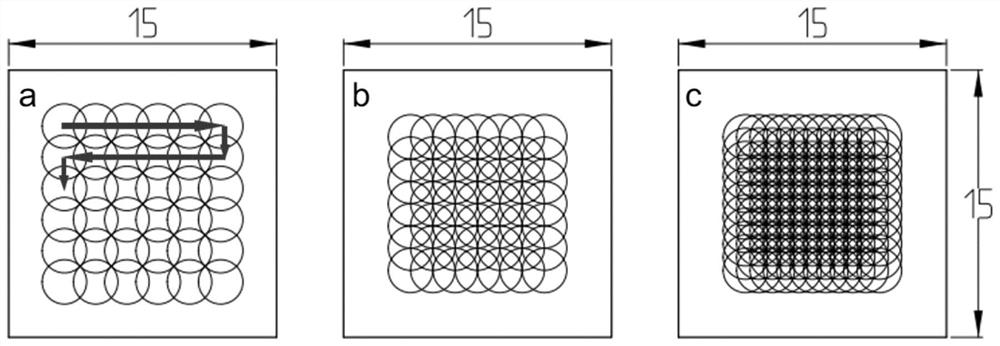

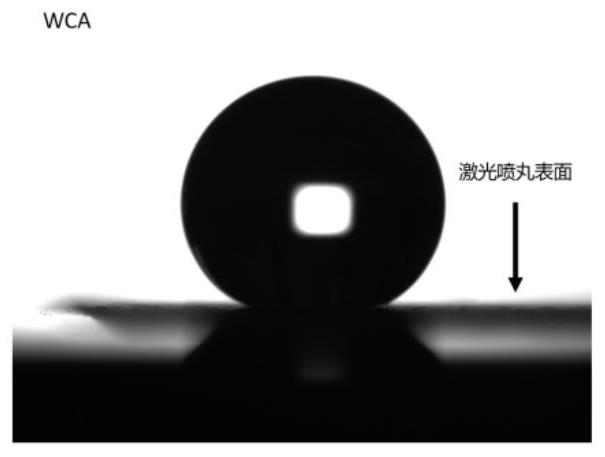

[0029] S02: Install the processed workpiece on the fixture of the laser peening process, use the surface of the aluminum alloy material as the absorption layer, and contain a mixed organic solution composed of 5ml perfluorooctyltriethoxysilane, 100ml ethanol solution and 50ml distilled water Prepare a 2mm-thick organic solution confinement layer; the output parameters of Nd:YAG solid-state laser are: wavelength 1064nm, repetition frequency 10Hz, pulse width 8ns, single pulse energy 1.5J, set the overlap rate of spots between rows and columns to 20 %, the laser s...

Embodiment 2

[0033] S01: The surface of the 2024-T351 aluminum alloy workpiece prepared by wire cutting was smoothed and polished with sandpaper of different particle sizes, and then the surface of the polished workpiece was ultrasonically cleaned with acetone solution for 5 minutes.

[0034] S02: When preparing the superhydrophobic surface of aluminum alloy by laser peening, use the surface of the material as the absorption layer, and prepare a 2mm thick organic solution with a mixed organic solution consisting of 7ml perfluorooctyltriethoxysilane, 150ml ethanol solution and 40ml distilled water As a confinement layer; the output parameters of Nd:YAG solid-state laser are: wavelength 1064nm, repetition frequency 10Hz, pulse width 8ns, single pulse energy 2J, set the spot overlap rate between rows and columns to be 50%, and the laser spot diameter is 500μm; laser peening scanning path such as figure 2 As shown in b, the starting point of shot peening is in the upper left corner of the wor...

Embodiment 3

[0038] S01: The surface of the 2024-T351 aluminum alloy material is polished with sandpaper of different particle sizes in sequence, and then the scratches and cracks on the polished surface are observed with a metallographic microscope. After meeting the requirements, the surface is polished on a metallographic grinding and polishing machine to make the surface rough. Degree ≤ 0.05mm, and finally ultrasonically clean the polished surface in absolute ethanol solution;

[0039] S02: When using a high-energy short-pulse laser to perform shot peening on the surface of an aluminum alloy workpiece, use the surface of the material as the absorbing layer, and prepare a mixed organic solution containing 10ml of perfluorooctyltriethoxysilane, 200ml of ethanol solution and 50ml of distilled water A 2mm thick organic solution is used as the confinement layer; the output parameters of the Nd:YAG solid-state laser are: wavelength 1064nm, repetition frequency 10Hz, pulse width 8ns, single pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Static contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com