Bacteriostatic regenerated cellulose fiber

A technology of regenerated cellulose and fiber, applied in the direction of carbon fiber, single-component cellulose rayon, fiber treatment, etc., can solve the problems of poor elasticity, softness, and limited antibacterial ability of bamboo fiber, and achieve the purpose of supplementing antibacterial components Effects of loss, loss mitigation, and toughness reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

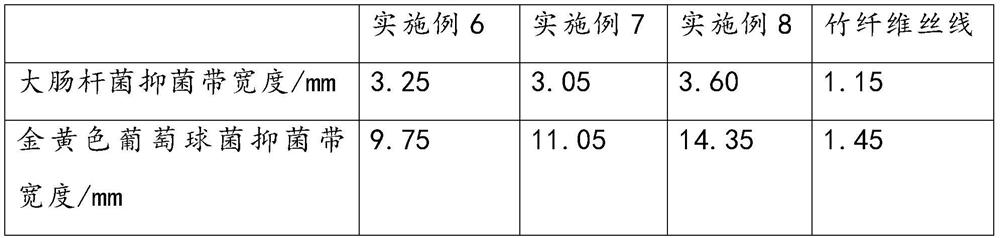

Examples

Embodiment 1

[0037] This embodiment prepares a kind of modified fiber, and specific implementation process is as follows:

[0038] Step B1: Mix 100g of carbon nanofibers and 280mL of concentrated nitric acid with a mass fraction of 68% to make a suspension, then add 350mL of 20% hydrogen peroxide dropwise to the suspension under stirring, and after the addition is completed Continue to stir and react for 3 hours, then alternately wash and filter with ethanol and water until the pH value of the washing liquid reaches 6, dry the filter cake in vacuum, then grind it in a dry grinder, pass through a 800-mesh sieve after grinding, and obtain the pretreatment fiber;

[0039] Step B2: Mix 100g of pretreated fibers with 32mL of propylene oxide, add 300mL of deionized water and ultrasonically disperse at 28kHz for 20min, then add 45g of ultrafine chitosan powder, stir and react in an ice-water bath for 8h, then heat up to 60°C Continue to stir and react to remove propylene oxide, and finally filte...

Embodiment 2

[0041] The present embodiment prepares a kind of antibacterial protein fiber, and specific implementation process is as follows:

[0042] Step A1: Dissolve sodium carbonate in water and adjust the pH value to 8 to make lye, then take 1kg of uncocooned raw silk and put it into the lye for soaking, stir once every 20 minutes during the soaking process, soak for 2 hours, take out the kneaded silk and use Wash and rinse once, repeat 3 times to remove the colloid on the surface of raw silk, expose the inner silk protein, and obtain degummed silk;

[0043] Step A2: Dissolve 1-butyl-3-methylimidazolium chloride salt in water to form a solution with a mass fraction of 17%, take a small amount of solution and degummed silk and add it to the mixer, heat up to 50±5°C and stir , slowly add the dissolving solution while stirring until the degummed silk is completely dissolved, then pour the dissolving solution dissolved with the degummed silk into the dialysis column, pressurize to 6bar fo...

Embodiment 3

[0046] The present embodiment prepares a kind of antibacterial protein fiber, and specific implementation process is as follows:

[0047]Step A1: Dissolve sodium hydroxide in water and adjust the pH value to 9 to make lye, then take 1 kg of uncocooned raw silk and put it into the lye for soaking, stir once every 20 minutes during soaking, soak for 2 hours, take out and knead Silk and wash once, repeat twice to remove the colloid on the surface of raw silk, expose the inner silk protein, and obtain degummed silk;

[0048] Step A2: Dissolve 1-butyl-3-methylimidazolium chloride salt in water to form a solution with a mass fraction of 22%, take a small amount of solution and degummed silk and add it to the mixer, heat up to 50±5°C and stir , slowly add the solution while stirring until the degummed silk is completely dissolved, then pour the solution dissolved with the degummed silk into the dialysis column, pressurize to 6bar for dialysis, wherein the molecular weight cut-off of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com