Preparation method of sulfur and phosphorus doped carbon material and product and application of sulfur and phosphorus doped carbon material

A carbon material, sulfur doping technology, applied in chemical instruments and methods, nano-carbon, carbon compounds, etc., can solve the problems of uneven dispersion of platinum nanoparticles, difficult platinum loading, low catalytic activity, etc., and achieve excellent mass ratio. Activity, the effect of improving catalytic activity and its stability, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0086] The invention provides a method for preparing a sulfur-phosphorus-doped carbon material, comprising: contacting the sulfur-doped carbon material with a phosphorus source, and treating (preferably constant temperature treatment) at 300°C to 800°C for 0.5h to 10h in an inert gas, The sulfur-phosphorus-doped carbon material is obtained.

[0087] According to the preparation method of the sulfur-phosphorus-doped carbon material of the present invention, the sulfur-doped carbon material is preferably mixed with a phosphorus source, and then treated (preferably constant temperature treatment) at 300°C to 800°C for 0.5h to 10h in an inert gas. One mixing method is to mix the sulfur-doped carbon material with the phosphorus source solution, impregnate and then dry; the phosphorus source solution is preferably an aqueous phosphorus source solution.

[0088] According to the preparation method of sulfur and phosphorus doped carbon materials of the present invention, the phosphorus ...

Embodiment 1

[0179] This example is used to illustrate the sulfur and phosphorus doped carbon material of the present invention.

[0180] Mix Vulcan XC72 and elemental sulfur evenly, the mass ratio of the two is 10:1, put it in a tube furnace, raise the temperature of the tube furnace to 1400 °C at a rate of 8 °C / min, and then treat it at a constant temperature for 2 hours. After cooling down naturally A sulfur-doped carbon material is obtained.

[0181] Immerse 1g of the aforementioned sulfur-doped carbon material in 15mL of 3wt% phosphoric acid aqueous solution for 24h; dry it in an oven at 100°C; then put it into a tube furnace, and raise the temperature of the tube furnace at a rate of 10°C / min to 500°C, constant temperature treatment for 3 hours; after natural cooling, a sulfur-phosphorus-doped carbon material was obtained, numbered as carbon carrier A.

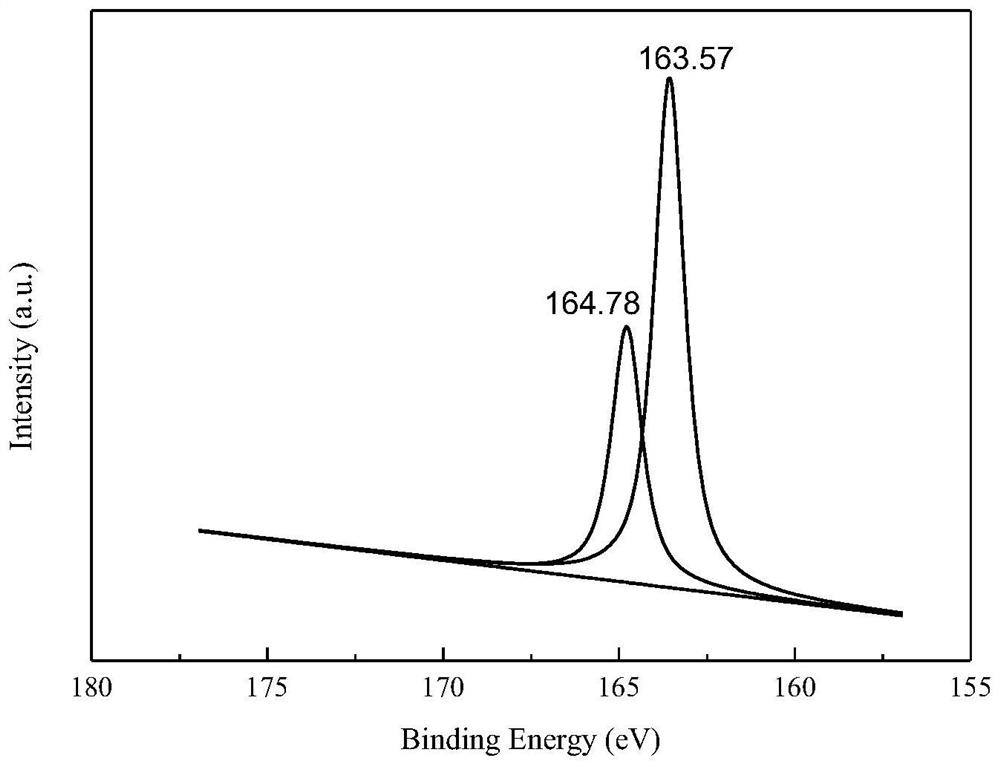

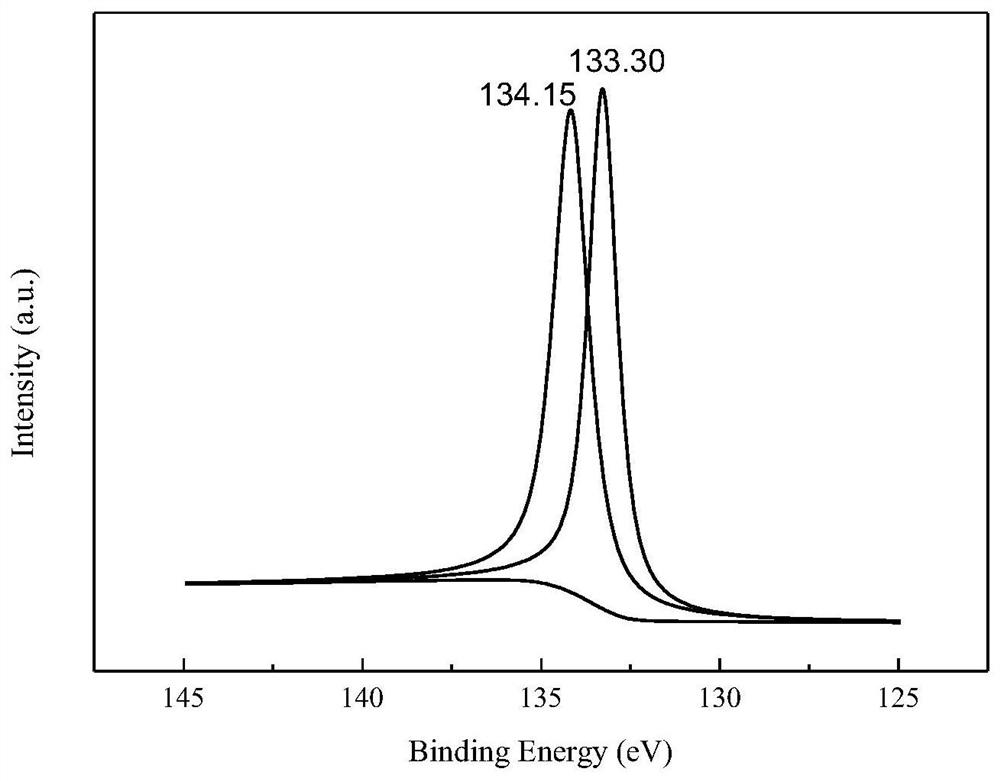

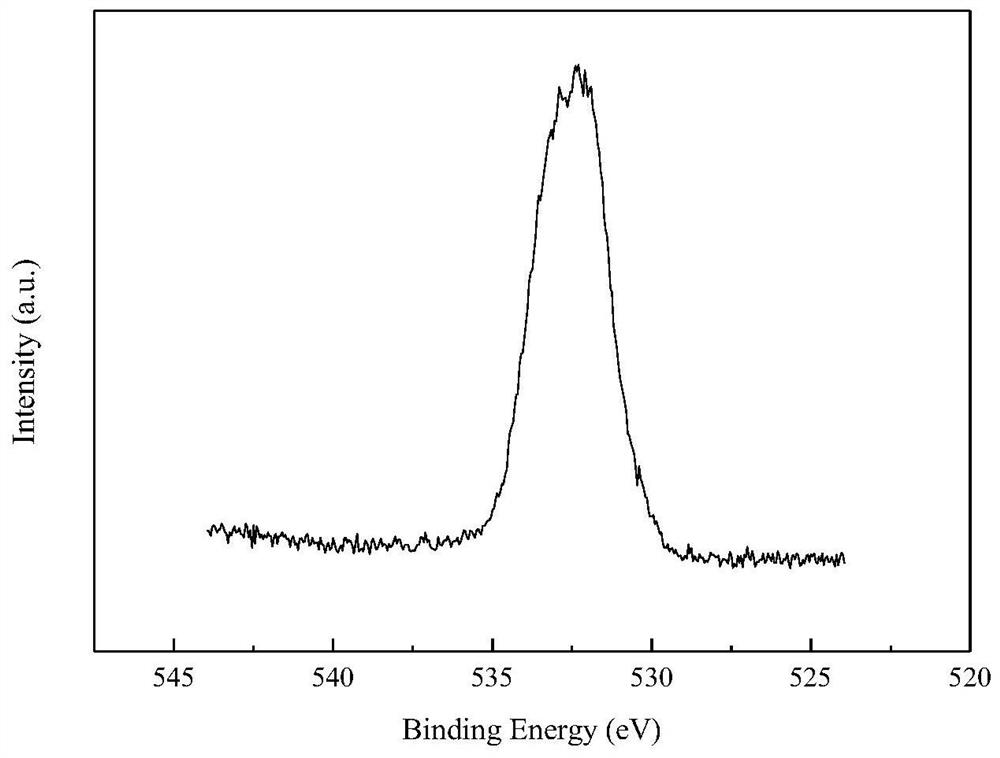

[0182] Sample Characterization and Testing

[0183] For the sulfur-phosphorus-doped carbon material in this example, the mass fra...

Embodiment 2

[0188] This example is used to illustrate the sulfur and phosphorus doped carbon material of the present invention.

[0189] Mix Ketjenblack ECP600JD and elemental sulfur evenly, the mass ratio of the two is 4:1, put it in a tube furnace, raise the temperature of the tube furnace to 1200 °C at a rate of 5 °C / min, and then treat it at a constant temperature for 2 hours. After cooling down naturally A sulfur-doped carbon material is obtained.

[0190] Add 1g of the aforementioned sulfur-doped carbon material to 35mL of 0.1wt% phosphoric acid aqueous solution and impregnate for 24h; dry it in an oven at 100°C; then place it in a tube furnace, and raise the temperature of the tube furnace at a rate of 9°C / min to 400° C., and then treated at a constant temperature for 3 hours. After natural cooling, a sulfur-phosphorus-doped carbon material was obtained, which was designated as carbon support B.

[0191] Sample Characterization and Testing

[0192] For the sulfur-phosphorus-doped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com