Preparation method of MnO2-coated Ni (OH) 2/NF capacitor electrode

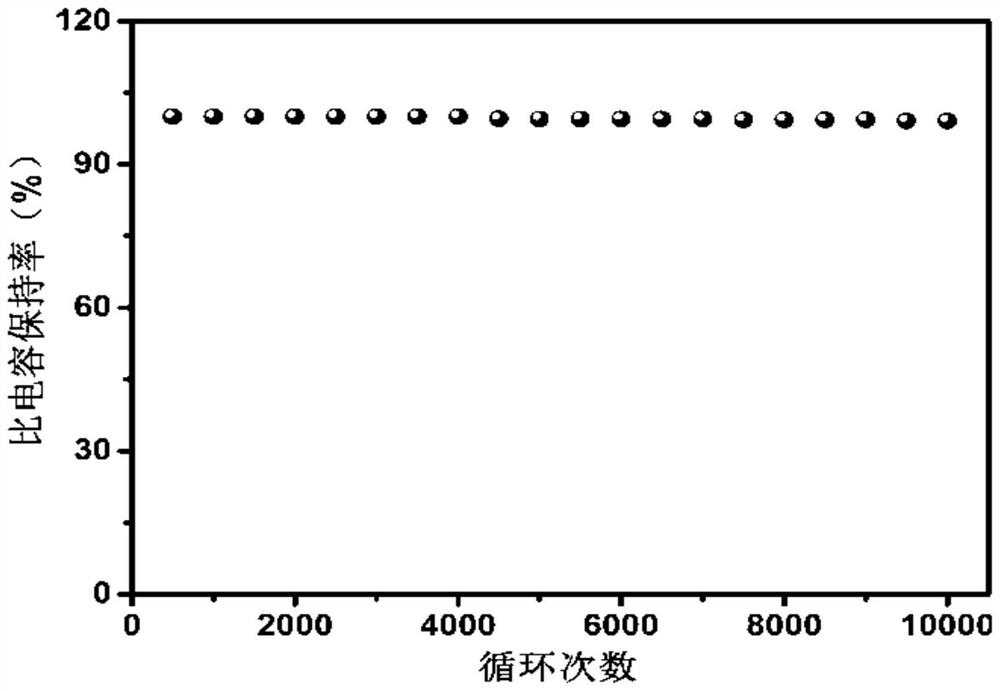

A capacitor electrode and electrode technology, which is applied in the field of preparation of MnO2@Ni2/NF capacitor electrodes, can solve the problems of decreased energy storage performance, electrode structure damage, damaged structure, etc., and achieves excellent electrochemical energy storage, no attenuation of specific capacitance, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

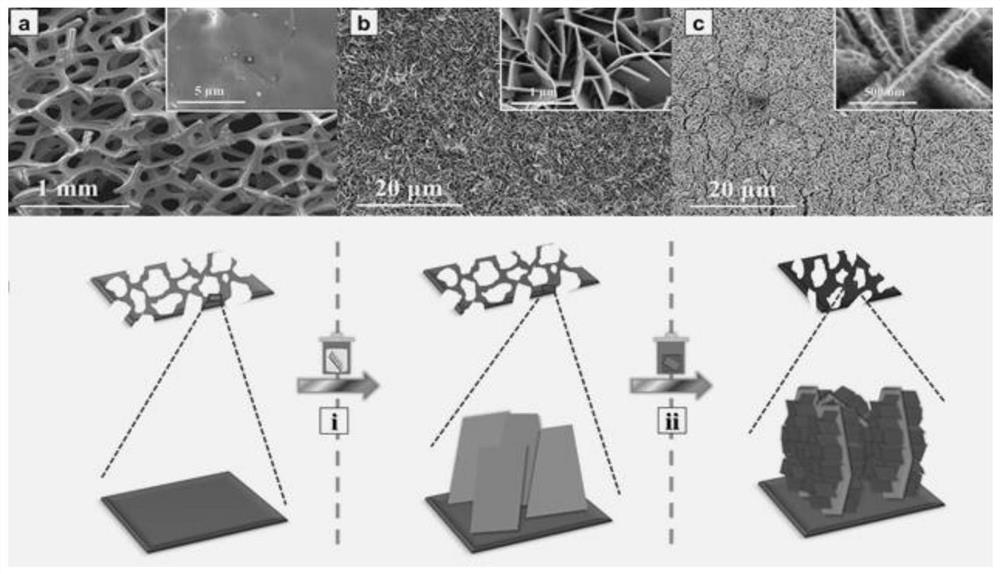

[0035] A kind of MnO 2 @Ni(OH) 2 / NF capacitor electrode, made according to the following steps:

[0036] 1. MnO 2 @Ni(OH) 2 Preparation of / NF electrode:

[0037] (1) Raw material pretreatment:

[0038] Cut foam nickel (NF) into 3.5 × 1.5 cm rectangular pieces, then immerse in 25ml of hydrochloric acid solution with a volume fraction of 18%~25% for ultrasonic treatment for 25min, take it out, then place it in 50~80ml deionized water, and ultrasonicate for 45 minutes , and then place the treated NF in a blast drying oven, set the temperature at 55°C, dry for 22 hours, take it out, and set it aside;

[0039] (2) Ni(OH) 2 Preparation of / NF:

[0040] Put the NF treated in step (1) in a high-temperature hydrothermal kettle, add 45ml of deionized water, seal it and place it in an electric blast drying oven at 145°C, and react for 20 hours. After the reaction is completed, cool it down to room temperature naturally. Take out the reactant, put it in a constant temperature dr...

Embodiment 2

[0099] A kind of MnO 2 @Ni(OH) 2 / NF capacitor electrode, made according to the following steps:

[0100] 1. MnO 2 @Ni(OH) 2 Preparation of / NF electrode:

[0101] (1) Raw material pretreatment:

[0102] Cut the nickel foam (NF) into 3.5 × 1.5 cm rectangular pieces, then immerse in 20ml of hydrochloric acid solution with a volume fraction of 18% for ultrasonic treatment for 30 minutes, take it out, put it in 50ml of deionized water, ultrasonic for 30 minutes, and then process it The NF is placed in a blast drying oven, set at a temperature of 50°C, dried for 20 hours, taken out, and set aside;

[0103] (2) Ni(OH) 2 Preparation of / NF:

[0104] Put the NF treated in step (1) in a high-temperature hydrothermal kettle, add 40ml of deionized water, seal it and place it in an electric blast drying oven at 140°C, react for 18 hours, and when the reaction is complete, cool it down to room temperature naturally. Take out the reactant, place it in a constant temperature drying ...

Embodiment 3

[0115] A kind of MnO 2 @Ni(OH) 2 / NF capacitor electrode, made according to the following steps:

[0116] 1. MnO 2 @Ni(OH) 2 Preparation of / NF electrode:

[0117] (1) Raw material pretreatment:

[0118] Cut foam nickel (NF) into 3.5 × 1.5 cm rectangular pieces, then immerse in 30ml of hydrochloric acid solution with a volume fraction of 25% for ultrasonic treatment for 20 minutes, take it out, put it in 80ml deionized water, ultrasonic for 30 minutes, and then process it The NF is placed in a blast drying oven, set the temperature at 60°C, dried for 25 hours, taken out, and set aside;

[0119] (2) Ni(OH) 2 Preparation of / NF:

[0120] Put the NF treated in step (1) in a high-temperature hydrothermal kettle, add 42ml of deionized water, seal it and place it in an electric blast drying oven at 150°C, and react for 24 hours. After the reaction is completed, cool naturally to room temperature. Take out the reactant, put it in a constant temperature drying oven at 55°C, dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com