Acetic acid hydrogenation catalyst, preparation method and application

A hydrogenation catalyst and catalyst technology, applied in the direction of molecular sieve catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of poor catalyst stability, short service life, catalyst corrosion, etc., achieve high conversion rate, improve catalytic activity, Improve the effect of acid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

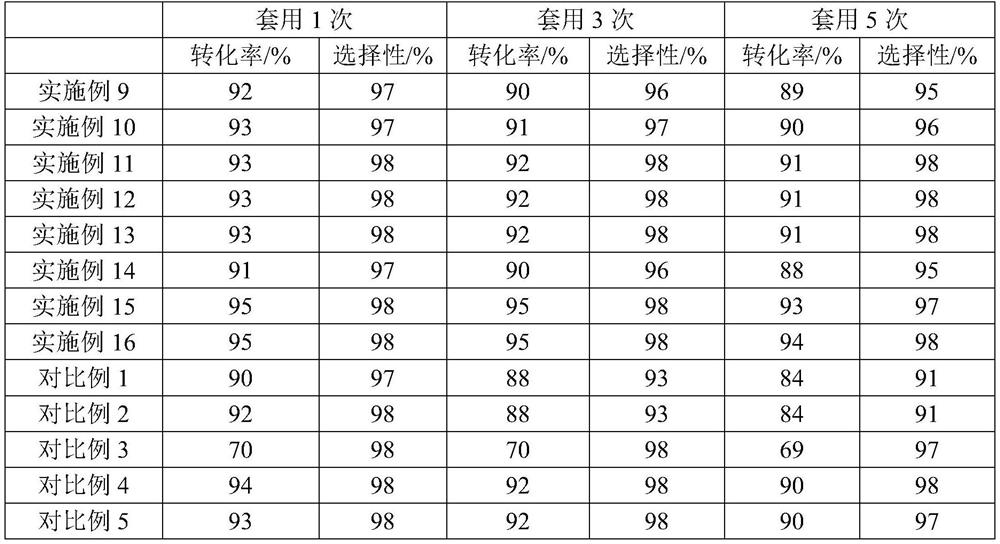

Examples

Embodiment 1

[0033] Add 90.38g of sodium silicate to 500mL deionized water, stir and dissolve at room temperature to obtain solution A; 23.63gCTAB, 14.87g Ni(NO 3 ) 2 ·6H 2 O was added to 500mL deionized water, heated and stirred until dissolved to obtain solution B. After the solution is cooled, add solution A to solution B, and use 1mol / L H 2 SO 4 Adjust the pH to 10 to obtain solution C. After the solution C was continuously stirred for 0.5 h, it was transferred to a stainless steel autoclave for a hydrothermal reaction at 120° C. for 24 h. After the reaction, the hydrothermal reaction solution was lowered to normal temperature, the solid was filtered out, washed with water until neutral, and dried; then the solid was ground into powder (particle size 5-10 μm), and placed in an open muffle furnace at 600°C for 3 hours. The metal Ni-modified MCM-41 molecular sieve (Ni modification amount 3%) was obtained, which was designated as Ni-MCM-1.

[0034] According to the above method and ...

Embodiment 2

[0038] Dissolve 100 mL of polyethylene glycol in 400 mL of distilled water, adjust the pH to 5 with 1 mol / L nitric acid, and then add 0.026 g of EuCl 3 and 0.17g AuCl 3 (molar ratio Au:Eu=5.4:1), 25% ammonia water was added dropwise to adjust the pH value to 10. The supernatant liquid was removed by centrifugation at 10,000 rpm, and the remaining solid was dried overnight at 180°C, and then roasted in a muffle furnace at 600°C for 5h. Finally got Au 2 o 3 -Eu 2 o 3 Composite metal oxides are denoted as AE-1.

[0039] The composite metal oxides AE-2, AE-3, AE-4, and AE-5 were prepared respectively by adjusting the material ratio according to the above method and the amount of raw materials in Table 2.

[0040] Table 2

[0041] EuCl 3 (g)

AuCl 3 (g)

Au:Eu AE-1 0.026 0.17 5.4:1 AE-2 0.026 0.27 8.9:1 AE-3 0.026 0.41 13.5:1 AE-4 0.026 0.52 17.1:1 AE-5 0.026 0.58 19.1:1

[0042] 【Example 1】

[0043] Take 0.5...

Embodiment 3

[0047] According to the method and the amount of raw materials in Example 1, AE-3 and Ni-MCM-2 were mixed to prepare a hydrogenation catalyst, which was designated as NMAE-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com