Preparation method and microscopic examination method of chitosan embedded calcium alginate microcapsule

A technology of calcium alginate and microcapsules, which is applied in the field of microcapsules, can solve the problems that there is no simple way to observe microcapsules, calcium alginate microcapsules require high sample preparation, and take a long time to achieve low cost of microscope inspection equipment, The microscopic inspection process is fast and convenient, and the effect of low shape requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

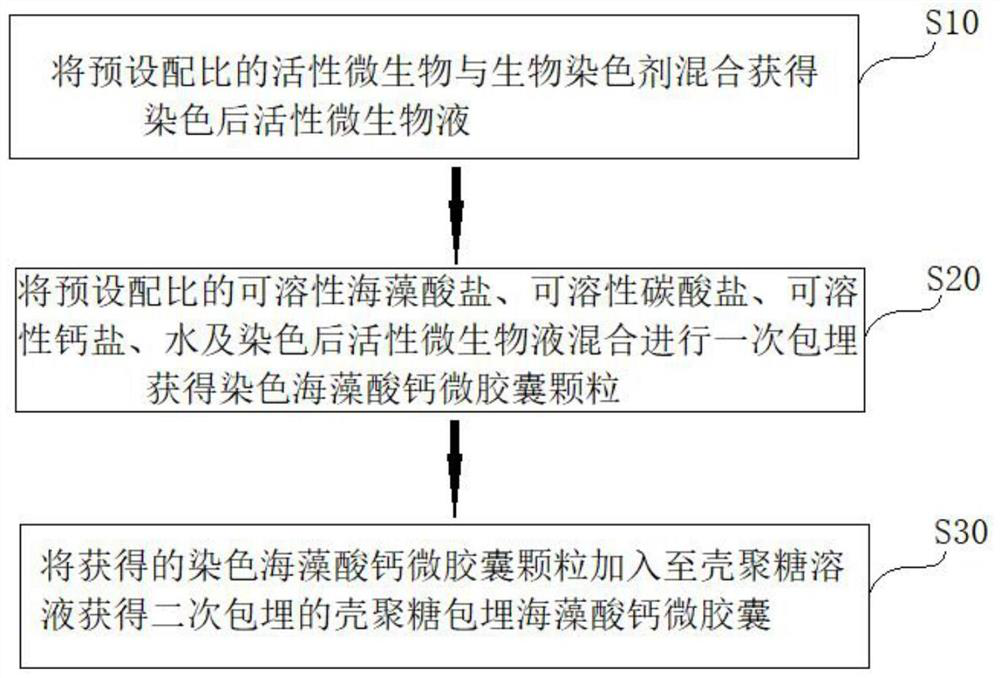

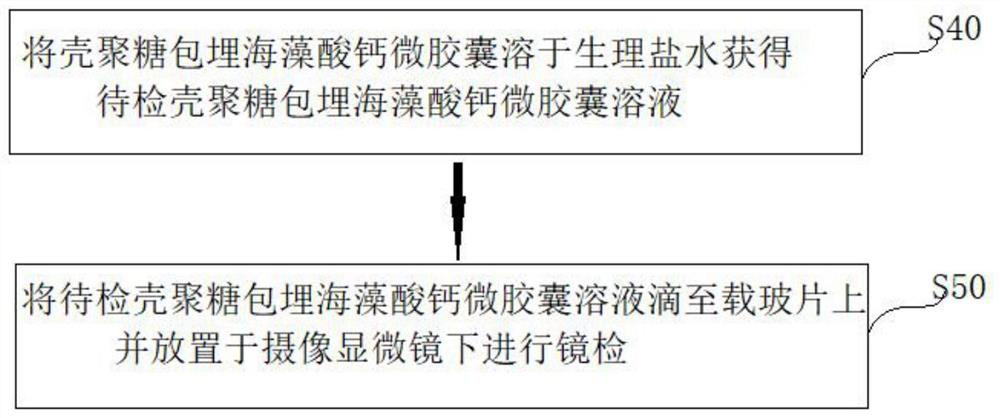

[0048] like figure 1 As shown, the preparation method of chitosan-embedded calcium alginate microcapsules in this embodiment includes the following steps:

[0049] S10. Mix the active microorganisms in the preset ratio with the biological dye to obtain the dyed active microorganism liquid.

[0050] In a preferred embodiment, the active microorganisms are concentrated edible fungi, preferably concentrated lactic acid bacteria, and the concentration of lactic acid bacteria is 2.0-4.0×10 11 CFU / mL.

[0051]The biological stain is a Gram stain, preferably a safranine stain and a crystal violet stain. Safranin is a basic dye that is soluble in water and can bind to nucleic acid in the nucleus and dye the nucleus red; crystal violet is also a basic dye that is soluble in water and can bind to nucleic acid in the nucleus and dye the nucleus. Dyed blue. In this example, safranin / crystal violet staining solution was used to dye the lactic acid bacteria sclerotia into red or blue. ...

Embodiment 1

[0091] First, 87.5ml concentration is 2.4 × 10 11 The lactic acid bacteria solution of CFU / ml was mixed with 87.5ml 25% safranine dye solution for 20min to obtain the lactic acid bacteria solution after staining. The concentration of the lactic acid bacteria solution after staining was 1.2×10 11 CFU / ml

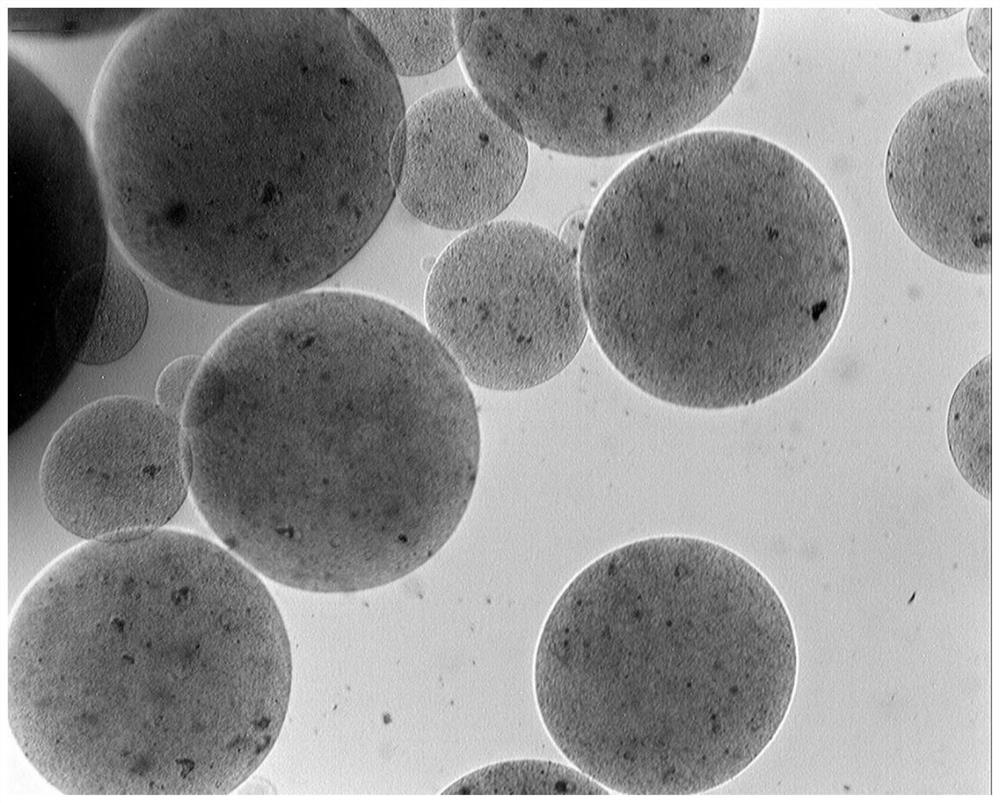

[0092] Then, the dyed lactic acid bacteria solution, 4% sodium alginate solution, 5% sodium carbonate solution, and 10% calcium chloride solution were stirred and mixed evenly according to the volume ratio of 175ml: 225ml: 36ml: 19ml, and then allowed to stand at 4°C for 1 hour. After degassing, a staining suspension was obtained. Then, according to the water-oil volume ratio of 30:100, the above dyeing suspension was added to soybean oil (containing 1.0% span80), and stirred for 30min at a rotating speed of 300r / min to form a water-in-oil (w / o) dyeing emulsion. In the obtained dyed emulsion, soybean oil containing 25% glacial acetic acid was added dropwise, and HAC and CaCO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com