Comprehensive utilization method of mixed C4-C5 material

A technology for mixing C4 and materials, which is applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problem of low comprehensive utilization rate of mixed C4 and C5 materials, and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

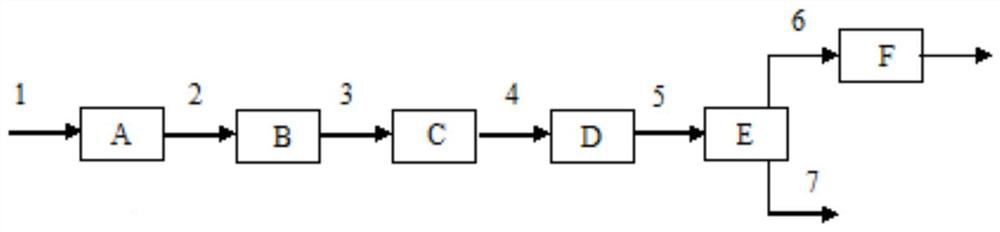

Image

Examples

Embodiment 1

[0049] The mixed C4C5 material composition (volume fraction %) of the steam cracking unit after extracting the olefin fraction is: isobutane: 27.0, n-butane: 25.8, butadiene: 1.2, isobutene: 1.8, butene-1: 42.4, butene-2: 1.8, isopentane: 12., n-pentane: 16, 1-pentene: 4.0, 2-pentene: 4.8, isopentene: 3.2.

[0050] Among them, in the selective hydrogenation unit, the selective hydrogenation catalyst is alumina-supported metal nickel, using a tubular fixed-bed reactor, the reaction temperature is 60 ° C, the reaction pressure is 2.5 MPa, and the reaction obtains stream I;

[0051] The stream I was transported to the dehydrogenation unit, and the dehydrogenation of alkanes was carried out in a fluidized bed reactor. The catalyst was metal platinum and tin supported on alumina, the reaction temperature was 560°C, and the reaction pressure was 0.3 MPa. After 1 hour of reaction, stream II was obtained. The composition of stream II is tested;

[0052] The stream II is transported t...

Embodiment 2

[0057] The mixed C4C5 material composition (volume fraction %) of the steam cracking unit after extracting the olefin fraction is: isobutane: 30, n-butane: 50, butadiene: 4, isobutene: 6, butene-1: 7. Butene-2:3.

[0058] Among them, in the selective hydrogenation unit, the selected hydrogenation catalyst is palladium supported on alumina, using a tubular fixed bed reactor, the reaction temperature is 50°C, and the reaction pressure is 3.0MPa to obtain stream I, and the composition of stream I is tested ;

[0059] The stream Ⅰ is transported to the dehydrogenation unit, and the alkane dehydrogenation adopts a tubular fixed-bed reactor, the catalyst is aluminum oxide supported metal platinum and tin, the reaction temperature is 560°C, and the reaction pressure is 0.2MPa, and the stream Ⅱ is obtained, and the stream Ⅱ The composition of the test;

[0060] The stream II is sent to the isomerization unit, and the isomerization of normal olefins adopts a single-stage fixed-bed re...

Embodiment 3

[0065] The mixed C4C5 material composition (volume fraction %) of the steam cracking unit after extracting the olefin fraction is: isobutane: 34, n-butane: 50, butadiene: 1, isobutene: 10, butene-1: 3. Butene-2:2.

[0066] Among them, in the selective hydrogenation unit, the selective hydrogenation catalyst is aluminum oxide supported metal nickel, using a tubular fixed bed reactor, the reaction temperature is 65°C, and the reaction pressure is 2.8MPa to obtain stream I, and the composition of stream I is analyzed. test;

[0067] The stream I is transported to the dehydrogenation unit, and the alkane dehydrogenation adopts a tubular fixed-bed reactor, the catalyst is aluminum oxide supported metal platinum and tin, the reaction temperature is 550°C, and the reaction pressure is 0.2MPa, and the stream II is obtained. Composition for testing;

[0068] The stream II is transported to the isomerization unit. The isomerization of normal olefins adopts a single-stage fixed-bed rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com