Preparation method and application of non-dry colored clay for children

A kind of color clay and children's technology, applied in the field of plasticine, can solve the problems of poor repeated use effect, poor plasticity of plasticine, no plasticity, etc., achieve good self-healing ability, not easy to decolorize, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The raw material composition of a kind of children's color mud is as shown in table 1:

[0041] Table 1 Raw material composition

[0042] Element content(%) Dimethyl hydroxy silicone oil 20 boric acid 0.2 Ferric chloride 0.1 Lauric acid 1 liquid paraffin 10 vaseline 10 flour 50 pigment 8.1 sodium benzoate 0.2 Ethylparaben 0.4 total 100

[0043] Preparation of the above-mentioned children's color mud:

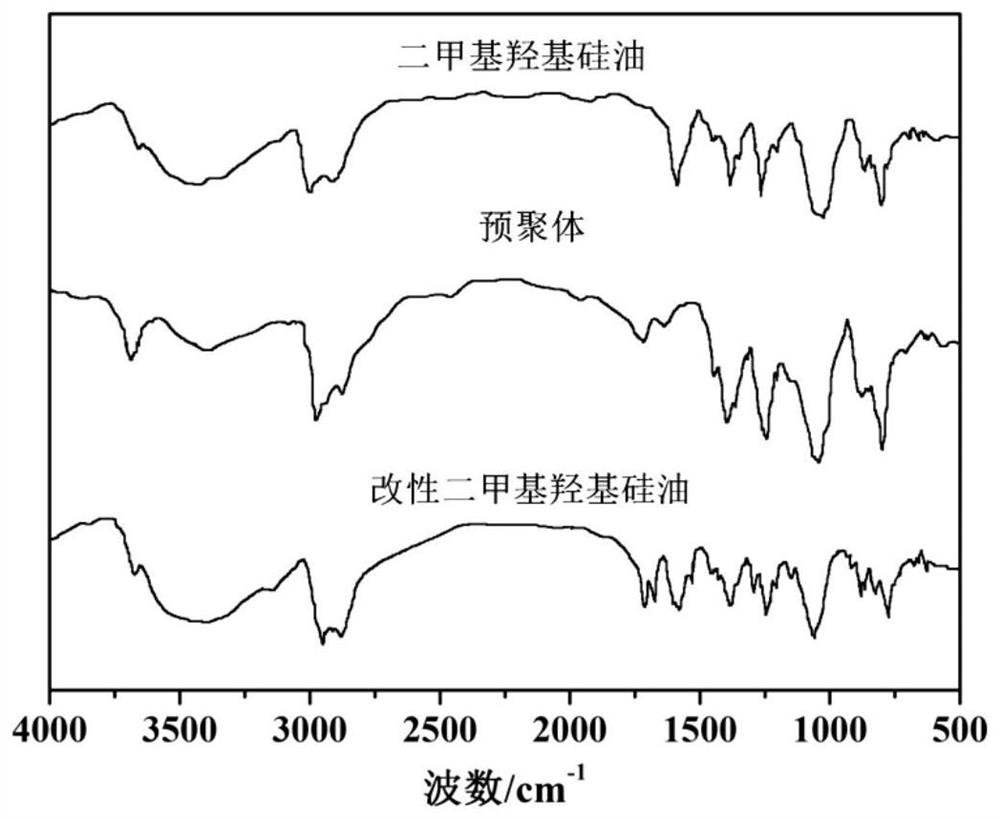

[0044] S1: Add dimethyl hydroxy silicone oil, boric acid, and ferric chloride into a kneader, and react at 156°C for 6 hours to obtain an oily colloid;

[0045] S2: add liquid paraffin and vaseline, stir evenly;

[0046] S3: Then add lauric acid and stir to form a soft gel;

[0047] S4: Finally, add sodium benzoate, ethylparaben, starch and pigment, and stir to shape.

Embodiment 2

[0049] A kind of raw material composition of children's color mud is as shown in table 2:

[0050] Table 2 Raw material composition

[0051] Element content(%) Dimethyl hydroxy silicone oil 18 boric acid 0.44 Ferric chloride 0.06 Lauric acid 0.7 liquid paraffin 8 vaseline 9 corn starch 56 pigment 7 sodium benzoate 0.25 Ethylparaben 0.55 total 100

[0052] The preparation of above-mentioned children's color mud is identical with embodiment 1.

Embodiment 3

[0054] The raw material composition of a kind of children's color mud is as shown in table 3:

[0055] Table 3 raw material composition

[0056] Element content(%) Dimethyl hydroxy silicone oil 27 boric acid 0.8 Ferric chloride 0.08 Lauric acid 0.9 liquid paraffin 6 vaseline 8 tapioca flour 48 pigment 8.71 sodium benzoate 0.15 Ethylparaben 0.36 total 100

[0057] The preparation of above-mentioned children's color mud is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com