Recombinant engineering bacterium and application thereof in efficient conversion of L-pantoic acid lactone

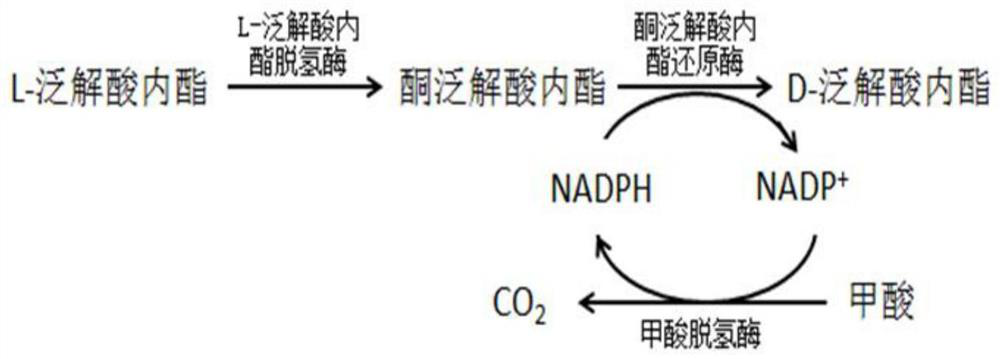

一种泛解酸内酯、重组工程菌的技术,应用在基因工程领域,能够解决D-泛解酸内酯分离困难、大废料、增加处理困难等问题,达到缩短生产周期、降低生产成本、避免繁琐步骤的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

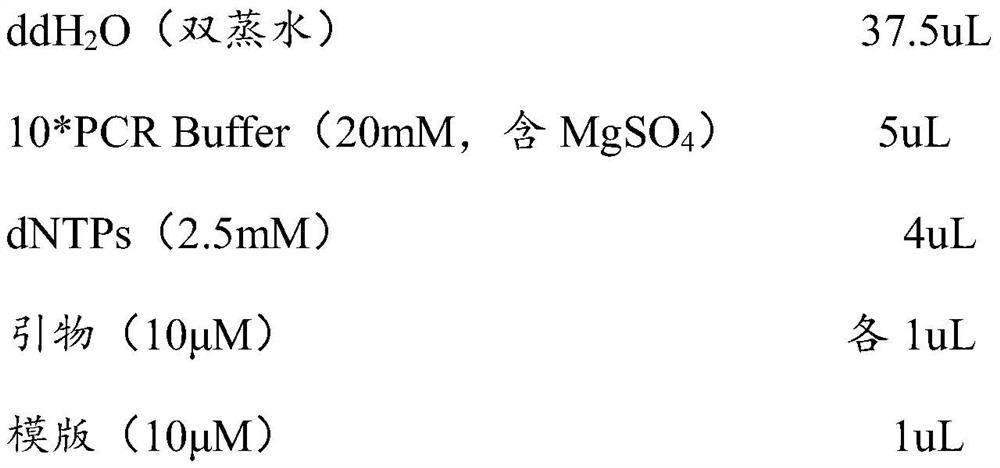

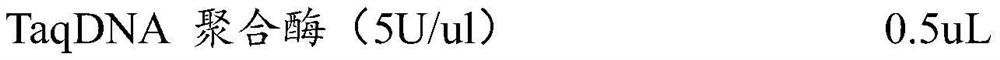

[0114] Example 1 Construction of Recombinant Engineering Bacteria

[0115] 1. Design and synthesis of target genes 1-3

[0116] Step 1, the nucleotide sequence of the L-pantolactone dehydrogenase coding gene derived from Humibacter sp.BT305 (actinomycetes) is codon-optimized according to the codon preference of Escherichia coli (E.coli) , obtain the modified gene sequence of L-pantolactone dehydrogenase, the nucleotide sequence of which is shown in SEQ ID NO.1;

[0117] Step 2, the nucleotide sequence of the ketopantolide reductase gene encoding gene derived from Candida magnolia was codon-optimized according to the codon preference of Escherichia coli (E.coli) to obtain D-ketopantolide Acid lactone modified gene sequence, the nucleotide sequence of which is shown in SEQ ID NO.2;

[0118] Step 3, the nucleotide sequence of the formate dehydrogenase encoding gene derived from Burkholderia is optimized according to the codon preference of Escherichia coli (E.coli), and the m...

Embodiment 2

[0156] Example 2 Induced Expression of Recombinant Engineering Bacteria

[0157] Inoculate the recombinant engineered bacteria prepared in Example 1 into 5mL LB medium according to the inoculum size of 2%, culture it at 37°C and 200rpm for 10-15h, and obtain the first-grade seed liquid;

[0158] The primary seed liquid was inoculated in 100 mL LB medium according to the inoculum amount of 2%, and it was placed at 37°C and 200 rpm for 8 hours to obtain the secondary seed liquid;

[0159] Secondary seed liquid is inoculated in the fermentor that contains 6L fermentation medium according to 0.2% inoculation amount, and described fermentation medium comprises magnesium sulfate heptahydrate 2g / L, potassium dihydrogen phosphate 7g / L, citric acid monohydrate 2g / L. L, ammonium sulfate 3g / L, yeast powder 1g / L and glucose 6g / L. Add glucose solution to keep the glucose concentration in the fermentation broth less than 5g / L, ferment and cultivate at pH 7, 37°C, and aerobic conditions f...

Embodiment 3

[0160] Example 3 Conversion of L-pantolactone

[0161] Add 130 g of L-pantolactone and 31.5 g of ammonium formate into the reaction vessel, add water to make the total volume 1 L, stir and dissolve, adjust the pH of the solution to 6.2 with 20-25% ammonia water, add the recombined solution collected in Example 2 After the engineered bacteria (OD=2), the mixed solution was stirred and reacted at a constant temperature of 37°C for 32 hours to obtain a reaction solution, in which the final concentration of D-pantolactone was 91g / L, and the final concentration of L-pantoate was 91g / L. The final concentration of the ester was 39 g / L, and the conversion rate of L-pantolactone was 70%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com