Preparation method of functionalized magnetic nanocomposite ferroferric oxide/silicon dioxide-APTMS

A magnetic nano and composite material technology, applied in the directions of alkali metal oxides/hydroxides, chemical instruments and methods, nanotechnology, etc. Simple equipment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

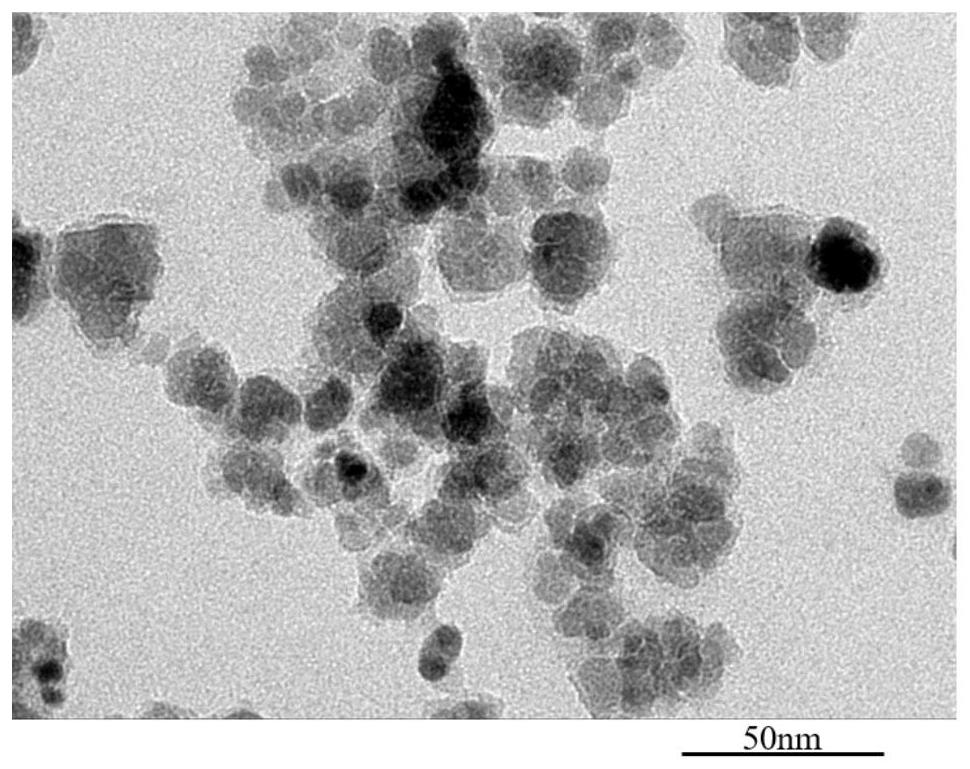

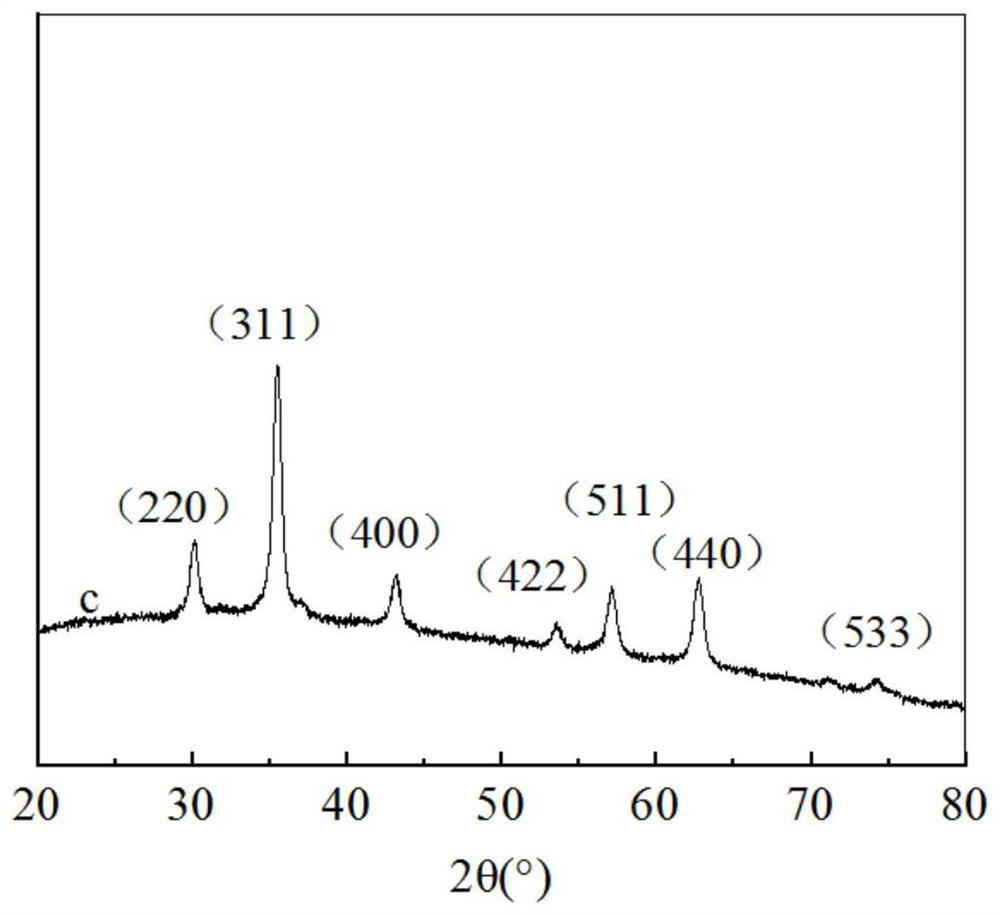

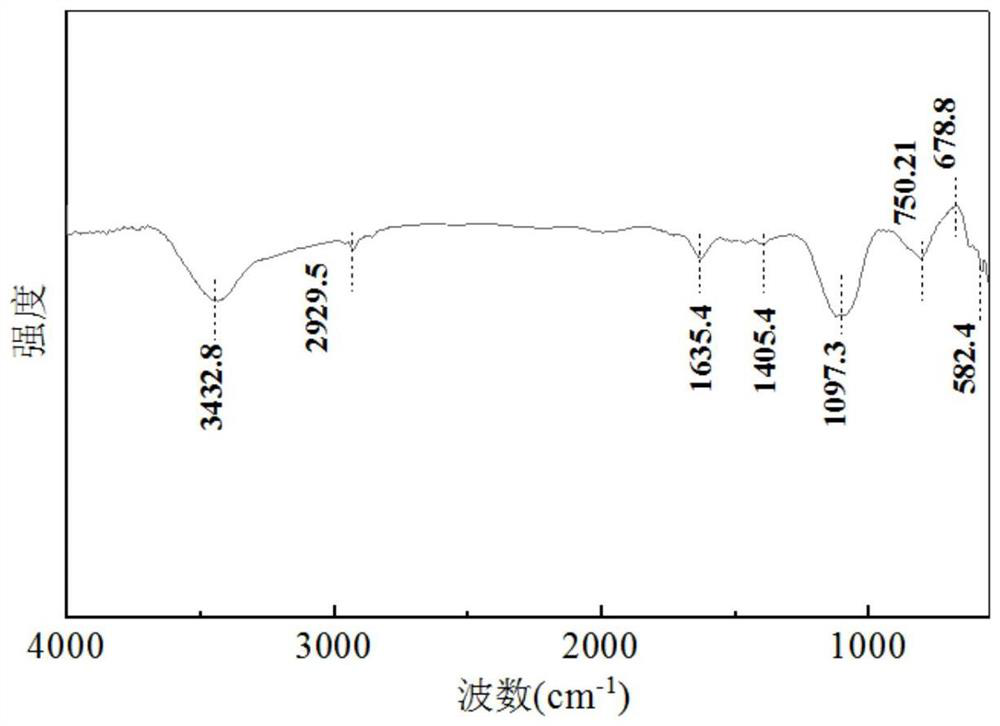

[0049] Under ultrasonic (40KHz, 150W) irradiation and nitrogen protection conditions, ferrous sulfate heptahydrate (2.78g, 0.01mol) and ferric chloride hexahydrate (4.05g, 0.015mol) were added to a three-necked flask, and 50mL was added to Ionized anaerobic water was mixed evenly, and ultrasonically stirred for 20min; a constant pressure dropping funnel was added dropwise a mixed solution of 14mL ammonia water and 100mL deionized anaerobic water into the flask at a dropping speed of 2s / drop; after the addition was completed, 1mL poly Ethylene glycol 400 (PEG-400) was used as a surfactant, and then 2 mL TEOS and 1.75 mL APTMS were added to introduce SiO 2 and -NH 2 group, stirred and reacted for 4 hours under ultrasonic irradiation at 40°C; after the reaction, magnetically separated, rinsed with oxygen-free deionized water (50mL×3) to prepare nanoparticles, dried in a vacuum oven at 50°C for 12h, and the functional Fe Fe 3 o 4 @SiO 2 - APTMS magnetic nanocomposites.

[005...

Embodiment 2

[0058] Under ultrasonic (40KHz, 150W) irradiation and nitrogen protection conditions, ferrous sulfate heptahydrate (2.78g, 0.01mol) and ferric chloride hexahydrate (4.05g, 0.015mol) were added to a three-necked flask, and 50mL was added to Ionized anaerobic water was mixed evenly, and ultrasonically stirred for 20 minutes; a constant pressure dropping funnel was added dropwise a mixed solution of 14mL ammonia water and deionized anaerobic water (100mL) into the flask at a rate of 2 s / drop; after the addition was completed, add 1mL polyethylene glycol 400 (PEG-400) as a surfactant, then add 2mL TEOS and 2mL APTMS to introduce SiO 2 and -NH 2 group, stirred and reacted for 4 hours under ultrasonic irradiation at 40°C; after the reaction, magnetically separated, and rinsed with oxygen-free deionized water (50mL×3) to prepare nanoparticles. Dry in a vacuum oven at 50°C for 12 hours to obtain functionalized Fe 3 o 4 @SiO 2 - APTMS magnetic nanocomposites.

[0059] TEM test res...

Embodiment 3

[0066] Under ultrasonic (40KHz, 150W) irradiation and nitrogen protection conditions, ferrous sulfate heptahydrate (2.78g, 0.01mol) and ferric chloride hexahydrate (4.05g, 0.015mol) were added to a three-necked flask, and 50mL was added to Ionized anaerobic water was mixed evenly, and ultrasonically stirred for 20 minutes; a constant pressure dropping funnel was added dropwise a mixed solution of 14mL ammonia water and deionized anaerobic water (100mL) into the flask at a rate of 2 s / drop; after the addition was completed, add 1mL polyethylene glycol 400 (PEG-400) was used as surfactant, then 2mL TEOS and 2.25mL APTMS were added to introduce SiO 2 and -NH 2 group, stirred and reacted for 4 hours under ultrasonic irradiation at 40°C; after the reaction, magnetically separated, and rinsed with oxygen-free deionized water (50mL×3) to prepare nanoparticles. Dry in a vacuum oven at 50°C for 12 hours to obtain functionalized Fe 3 o 4 @SiO 2 - APTMS magnetic nanocomposites.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com