Preparation method of ferrocene-porphyrin metal complex, ferrocene-porphyrin metal complex and bimetal-containing fuel oil additive

A metal complex, ferrocene technology, applied in the field of fuel additives, can solve the problems of insolubility, time-consuming and labor-intensive, DPF filtration efficiency reduction, etc., to reduce maintenance times and costs, save fuel maintenance times and costs, and solve passive regeneration. the effect of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

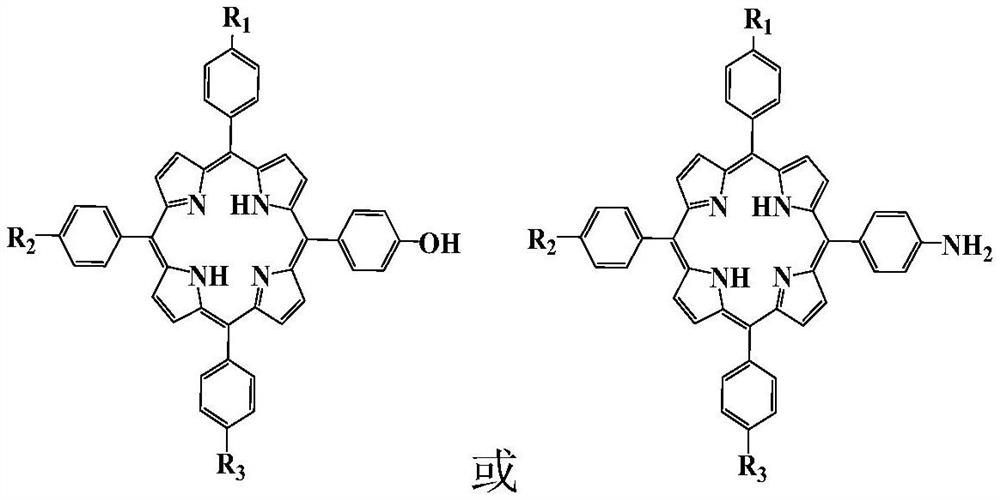

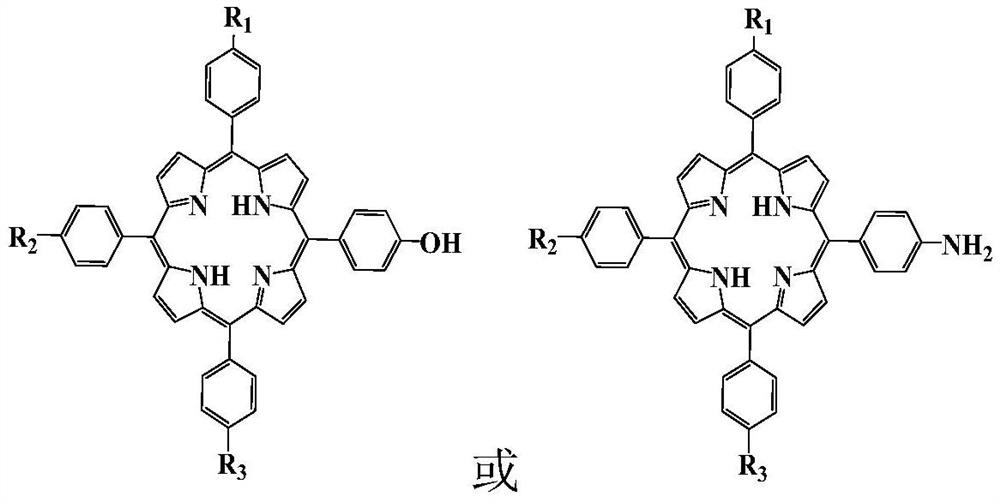

[0065] Preparation of porphyrin metal complex (cerium porphyrin): 5,10,15,20-tetrakis(4-hydroxyphenyl)porphyrin (50mmol) and cerium acetate (150mmol) were dissolved in N'N-dimethyl In formamide (50 mL), the reaction system was heated up to 150 °C for 8 h under magnetic stirring, and the reaction mixture was poured into ice water to precipitate cerium porphyrin, filtered with suction, washed with deionized water, and dried in vacuo to obtain Active hydroxyl porphyrin-cerium complexes.

[0066] Preparation of ferrocene-porphyrin cerium complex: Take 20mmol of porphyrin cerium metal complex with active hydroxyl group and 15mmol of ferrocenedicarboxylic acid dissolved in 50mL of dichloromethane, then add 1mL of triethylamine, under reflux condition The reaction was carried out for 6 hours. After the reaction was completed, the solvent was evaporated to obtain the ferrocene-porphyrin metal complex.

[0067] Preparation of fuel additives containing ferrocene-porphyrin cerium comple...

Embodiment 2

[0073] Preparation of porphyrin metal complex (platinum porphyrin): Monoaminotetraphenylporphyrin (400mmol) and platinum chloride (200mmol) were dissolved in N'N-dimethylformamide (50mL) and stirred under magnetic force The reaction system was heated to 120° C. for 2 h, and the reaction mixture was poured into ice water to precipitate the product, filtered with suction, washed with deionized water, and dried in vacuum to obtain a monoaminotetraphenylporphyrin-platinum complex.

[0074] Preparation of ferrocene-porphyrin platinum complex: Dissolve 200mmol of monoaminotetraphenylporphyrin-platinum metal complex and 400mmol of ferrocenedicarboxylic acid in 50mL of dichloroethane, then add 2mL of triethylamine, React under reflux conditions for 16h, evaporate the solvent after the completion of the reaction, and obtain the ferrocene-porphyrin platinum complex.

[0075] Preparation of bimetallic fuel additive containing ferrocene-porphyrin platinum complex: 2.3 parts by weight of f...

Embodiment 3

[0081] Preparation of porphyrin metal complex (cerium porphyrin): 5,10,15,20-tetrakis(4-hydroxyphenyl)porphyrin (50mmol) and cerium acetate (150mmol) were dissolved in N'N-dimethyl In formamide (50 mL), the reaction system was heated up to 150 °C for 8 h under magnetic stirring, and the reaction mixture was poured into ice water to precipitate cerium porphyrin, filtered with suction, washed with deionized water, and dried in vacuo to obtain Active hydroxyl porphyrin-cerium complexes.

[0082] Preparation of ferrocene-porphyrin cerium complex: Take 20mmol of porphyrin cerium metal complex with active hydroxyl group and 15mmol of ferrocenedicarboxylic acid dissolved in 50mL of dichloromethane, then add 1mL of triethylamine, under reflux condition The reaction was carried out for 6 hours. After the reaction was completed, the solvent was evaporated to obtain the ferrocene-porphyrin metal complex.

[0083]Preparation of fuel additives containing ferrocene-porphyrin cerium complex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com