Metal support filled with magnetic composite material and preparation method of metal support

A magnetic composite material and metal stent technology, which can be used in additive processing, prosthesis, tissue regeneration, etc., can solve the problem of inability to achieve cell filling and growth, achieve high porosity, stable mechanical structure, and promote angiogenesis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

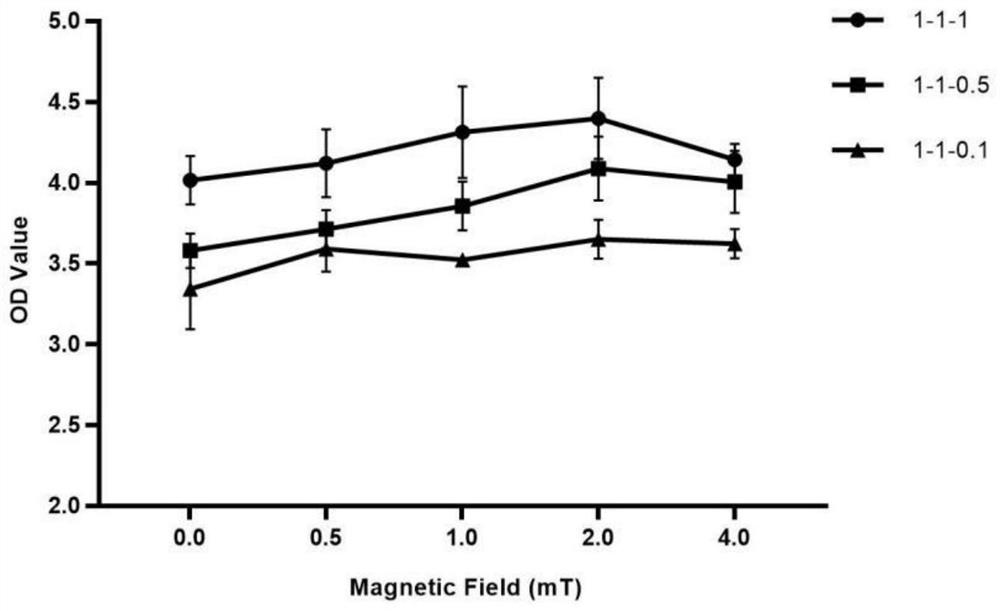

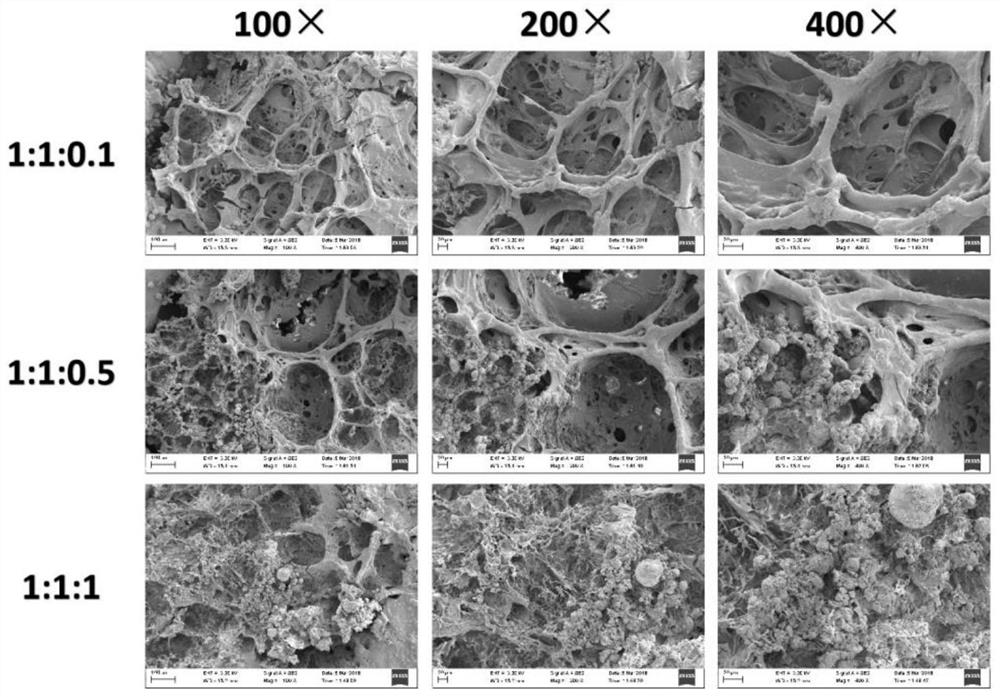

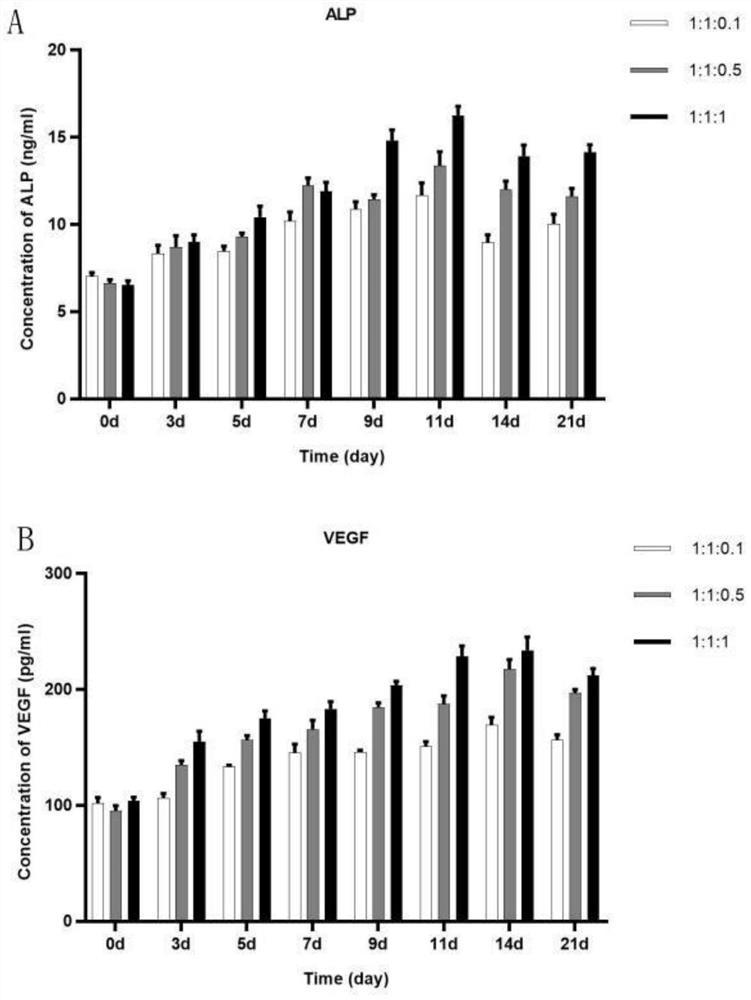

[0047] The titanium alloy stent filled with the magnetic composite material in this embodiment is prepared according to the mass ratio of nano-hydroxyapatite powder, gelatin and nano-magnetic particles at 1:1:1.

[0048] The preparation method of the titanium alloy stent filled with the above-mentioned magnetic composite material comprises the following steps:

[0049] (1) Use CAD software to construct a 3D digital model with a rhombohedral dodecahedron as the basic unit, a pore column of 300 μm, a pore diameter of 500 μm, and a porosity of 80%.

[0050] (2) printing a porous titanium alloy support according to the 3D digital model in step (1);

[0051] (3) 2.5g nano magnetic particle powder (γ-Fe 2 o 3 , Ruicun, ferric oxide wrapped with polydextrose sorbitol carboxymethyl ether) was dissolved in 50ml of deionized water, ultrasonically dispersed in an ultrasonic cleaning machine, and then treated with an ultrasonic cell pulverizer to uniformly disperse the nano-magnetic par...

Embodiment 2

[0062] The titanium alloy stent filled with the magnetic composite material in this embodiment is prepared according to the mass ratio of hydroxyapatite powder, gelatin and nano-magnetic particles at 1:1:0.5.

[0063] The preparation method of the titanium alloy stent filled with the above-mentioned magnetic composite material comprises the following steps:

[0064] (1) Use CAD software to construct a 3D digital model with a rhombohedral dodecahedron as the basic unit, a pore column of 300 μm, a pore diameter of 500 μm, and a porosity of 80%.

[0065] (2) printing a porous titanium alloy support according to the 3D digital model in step (1);

[0066] (3) Dissolve 1.25g of nano-magnetic particle powder in 50ml of deionized water, first ultrasonically disperse it in an ultrasonic cleaning machine, and then use an ultrasonic cell pulverizer to process the nano-magnetic particle evenly in deionized water, and obtain a mass solubility of 2.5% nanomagnetic particle solution.

[00...

Embodiment 3

[0071] The titanium alloy stent filled with the magnetic composite material in this embodiment is prepared according to the mass ratio of hydroxyapatite powder, gelatin and nano-magnetic particles of 1:1:0.1.

[0072] The preparation method of the titanium alloy stent filled with the above-mentioned magnetic composite material comprises the following steps:

[0073] (1) Use CAD software to construct a 3D digital model with a rhombohedral dodecahedron as the basic unit, a pore column of 300 μm, a pore diameter of 500 μm, and a porosity of 80%.

[0074] (2) printing a porous titanium alloy support according to the 3D digital model in step (1);

[0075] (3) Dissolve 0.25g of nano-magnetic particle powder in 50ml of deionized water, first ultrasonically disperse it in an ultrasonic cleaning machine, and then use an ultrasonic cell pulverizer to process the nano-magnetic particle evenly in deionized water, and obtain a mass solubility of 0.5% nanomagnetic particle solution.

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com