Method for utilizing renewable energy electricity

A technology for renewable energy and water electrolysis, applied in electrolysis components, electrolysis process, climate sustainability, etc., can solve the problems of restricted development and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

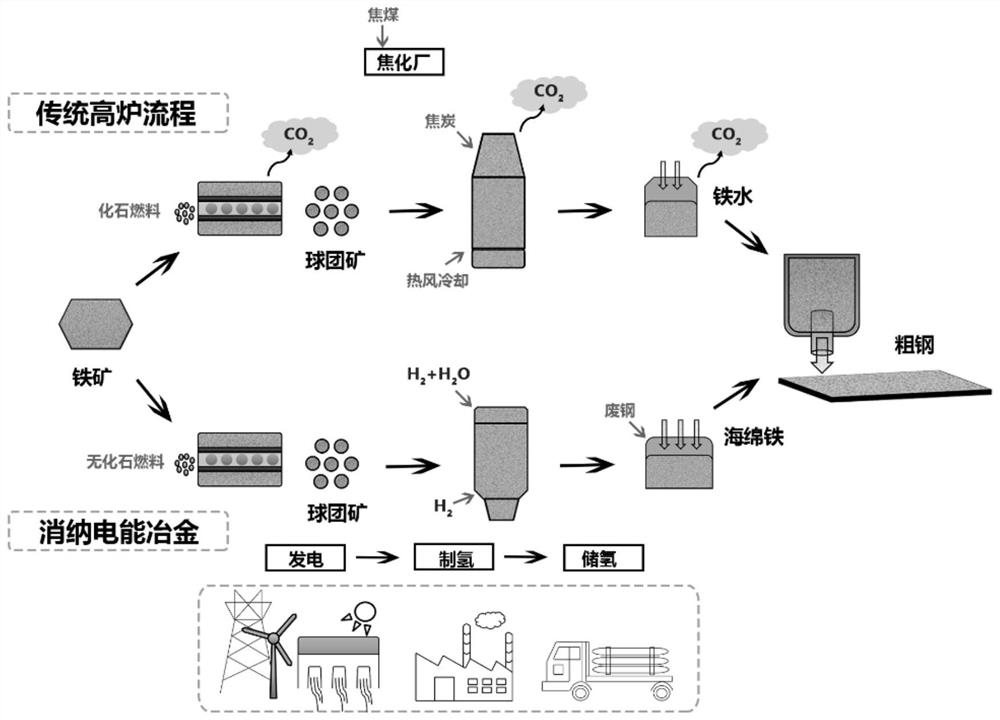

[0038] The following will be compared with the traditional coal-based blast furnace ironmaking process (such as figure 2 shown), the metallurgical process for consuming, converting and utilizing electric energy in this embodiment is described in detail. Among them, the traditional blast furnace ironmaking process is still the main method used in the world ironmaking technology due to its simple process, large production capacity and high efficiency. And research and develop new technology that meets the requirements of energy saving and emission reduction.

[0039] 1. Traditional coal-based blast furnace ironmaking process

[0040] (1) The mined iron ore is processed to generate iron oxide-rich products, which are made into pellets of 10 mm, and sent to the steel plant after drying, preheating, sintering, cooling, etc.

[0041] (2) Pellets, fuels (coke, pulverized coal, etc.) and other raw materials (limestone, dolomite, manganese ore, etc.) are loaded into the blast furnac...

Embodiment 2

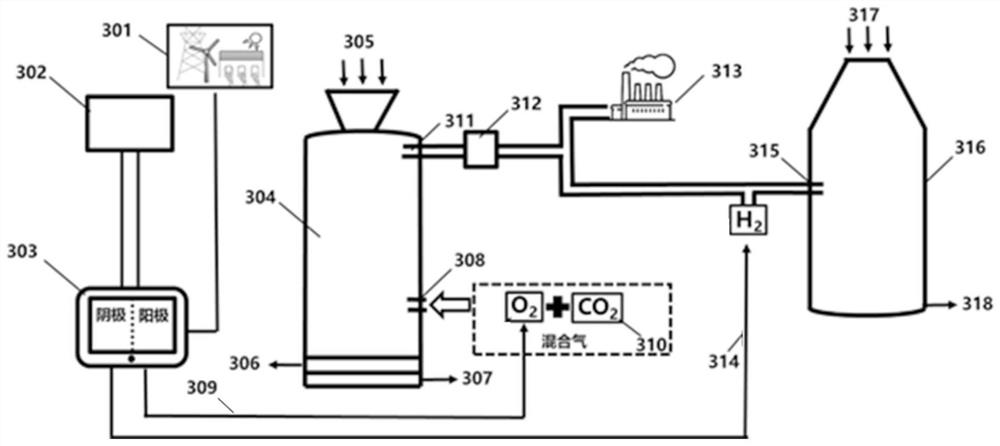

[0059] This embodiment provides a system for large-scale consumption, conversion and utilization of electrical energy for metallurgy, the structure of which is as follows image 3 shown. The system includes a power grid 301, a control device 302, a water electrolysis device 303, a blast furnace 304, a gas-based shaft furnace 316 and chemical equipment 313; wherein:

[0060] The blast furnace 304 is provided with a blast furnace inlet 305, a slag outlet 306, a tap outlet 307, a blast furnace air inlet 308, and a blast furnace gas outlet 311, wherein the blast furnace inlet 305 is used to input iron ore, reducing agent and other materials ; The slag outlet 306 is used to output slag; the iron outlet 307 is used to output molten iron; the blast furnace gas outlet 311 is used to output the blast furnace gas with low nitrogen concentration;

[0061] The gas-based shaft furnace 316 is provided with a gas-based shaft furnace inlet 315, a gas-based shaft furnace inlet 317, and a gas-...

Embodiment 3

[0076] This embodiment provides a system for large-scale consumption, conversion and utilization of electrical energy for metallurgy, the structure of which is as follows Figure 4 shown. The difference between this system and the system of Example 2 is only that the water electrolysis device 303 of this system is provided with a carbon dioxide gas supply device 3031, and the anode of the water electrolysis device 303 is connected to the carbon dioxide gas supply device 3031;

[0077] During the water electrolysis process, carbon dioxide is injected into the anode of the water electrolysis device 303 through the carbon dioxide supply device 3031, wherein the volume ratio of the oxygen produced by the anode to the injected carbon dioxide is controlled to be 1:1, so that the partial pressure of the mixed gas of the cathode and the anode reaches Balance to ensure the safety of the device;

[0078] The mixture of oxygen and carbon dioxide produced by the anode enters the blast fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com