Gate dielectric thin film transistor for SiC-based field effect transistor and preparation method of gate dielectric thin film transistor

A field effect transistor, thin film transistor technology, applied in transistors, semiconductor/solid-state device manufacturing, semiconductor devices and other directions, can solve the high technical threshold of semi-insulating silicon carbide layer, transistor silicon dioxide dielectric is broken down, and it is difficult to use silicon carbide. Advantages and other issues, to achieve the effect of improving breakdown resistance and reliability, no surface dangling bonds, and improving carrier mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

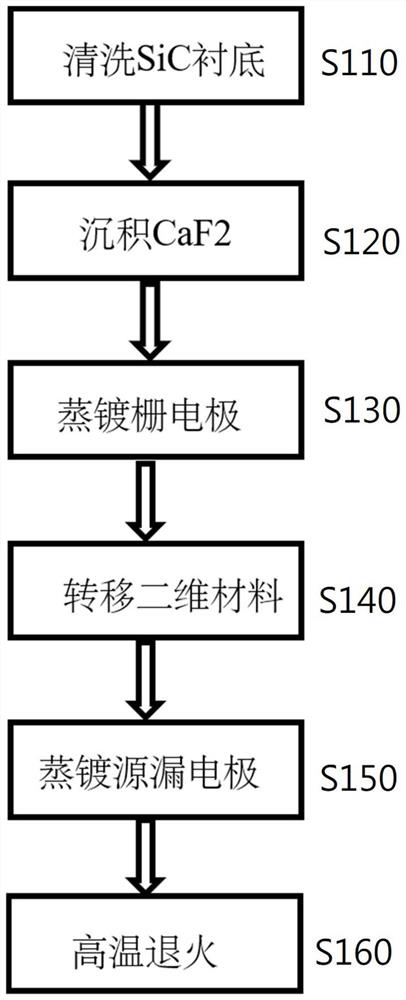

Method used

Image

Examples

Embodiment 1

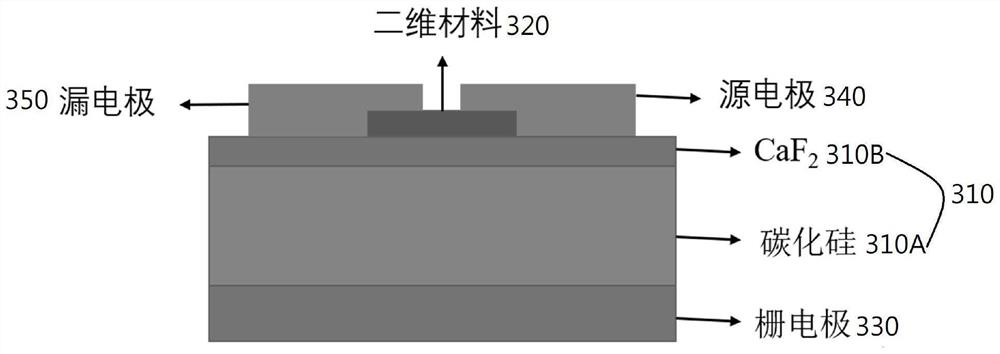

[0040] refer to image 3 , a gate dielectric thin film transistor 30 for a SiC-based field effect transistor, comprising a silicon carbide substrate 310A and a calcium fluoride film 310B, the calcium fluoride film 310B is deposited on the silicon carbide substrate 310A to form CaF 2 / SiC substrate 310, a two-dimensional material 320 is disposed on the calcium fluoride film 310B, and a two-dimensional material 320 is disposed on the calcium fluoride film 310B in a transfer manner.

[0041] As a further illustration of this example, the CaF 2 / SiC substrate 310 is vapor-deposited a metal film on the side of silicon carbide 310A opposite to calcium fluoride film 310B as gate electrode 330 , and annealed at 1000° C. for 5 minutes under nitrogen.

[0042] As a further description of this embodiment, the source electrode 340 and the drain electrode 350 are obtained by vapor-depositing metal on the two-dimensional material 320 , respectively. Using the laser direct writing method, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Bandgap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com