Vacuum laser device and method for instantaneous local heating and in-situ characterization of perovskite surface

A laser device and local heating technology, applied in laser welding equipment, metal processing equipment, sustainable manufacturing/processing, etc., can solve problems such as high cost, slow speed, and difficult to meet, to ensure quality and accuracy, reduce Difficulty in operation and convenient in-situ monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

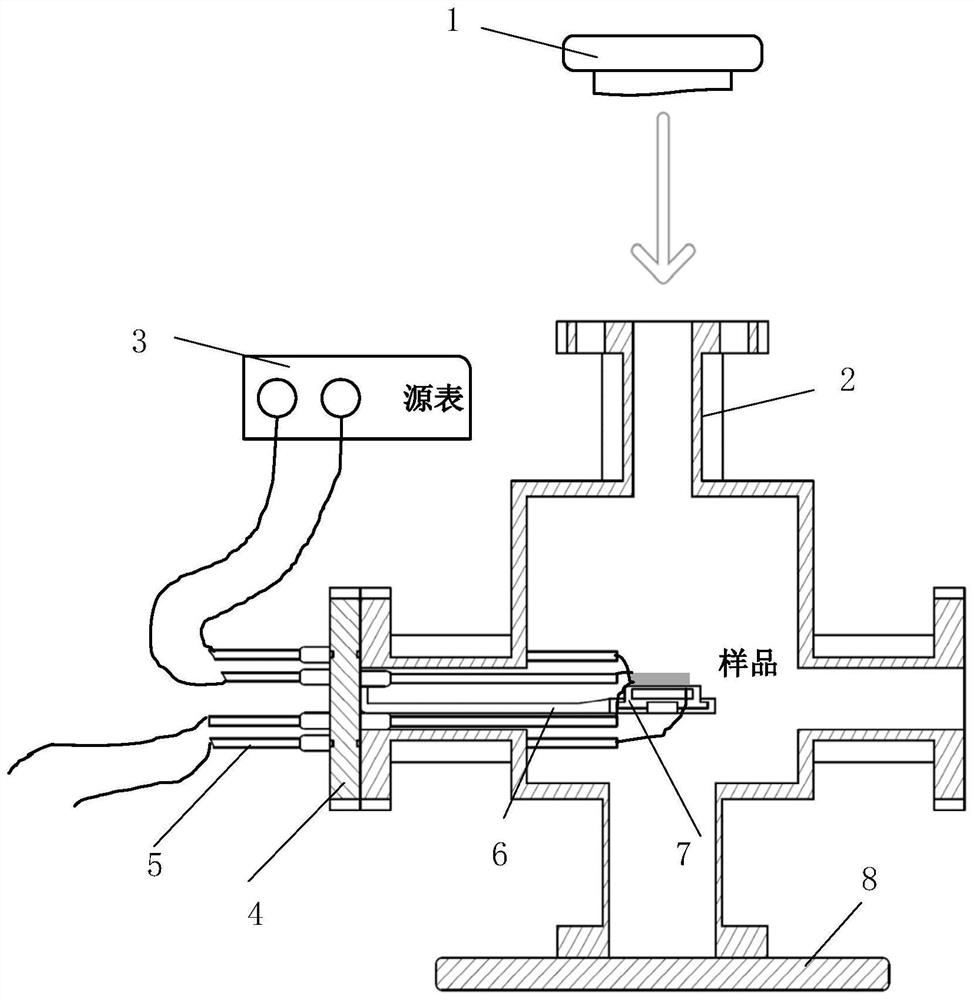

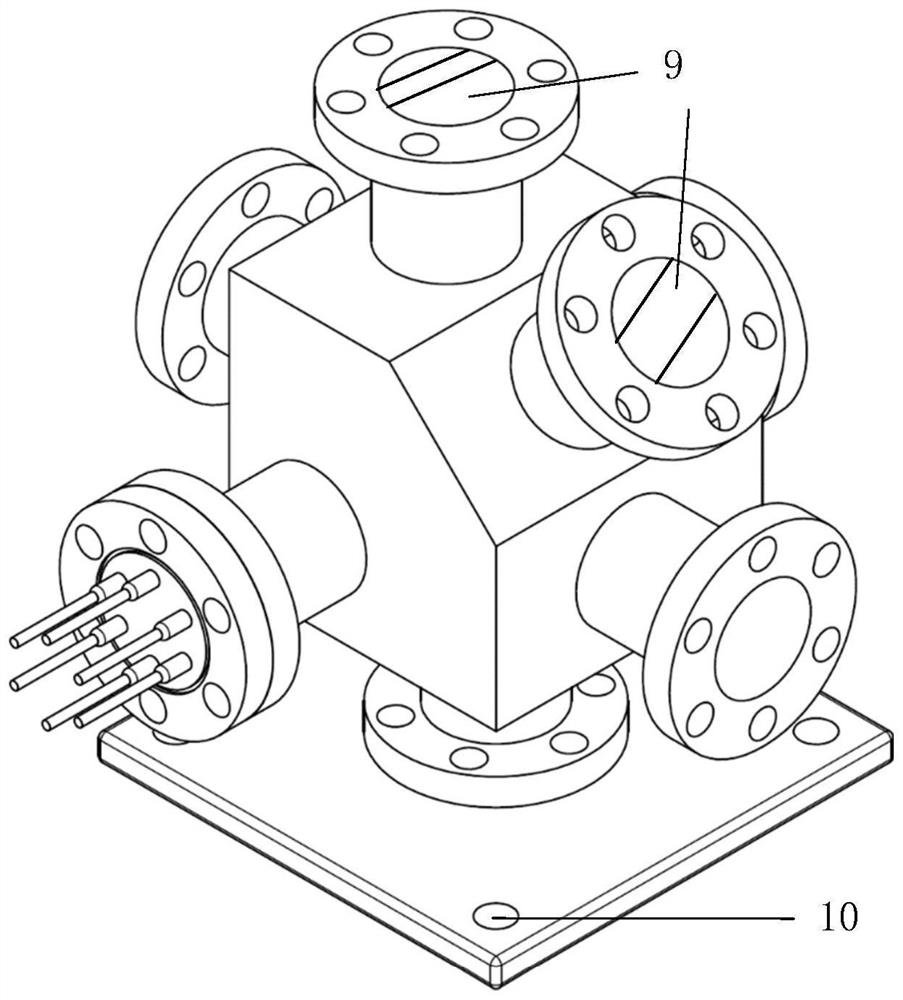

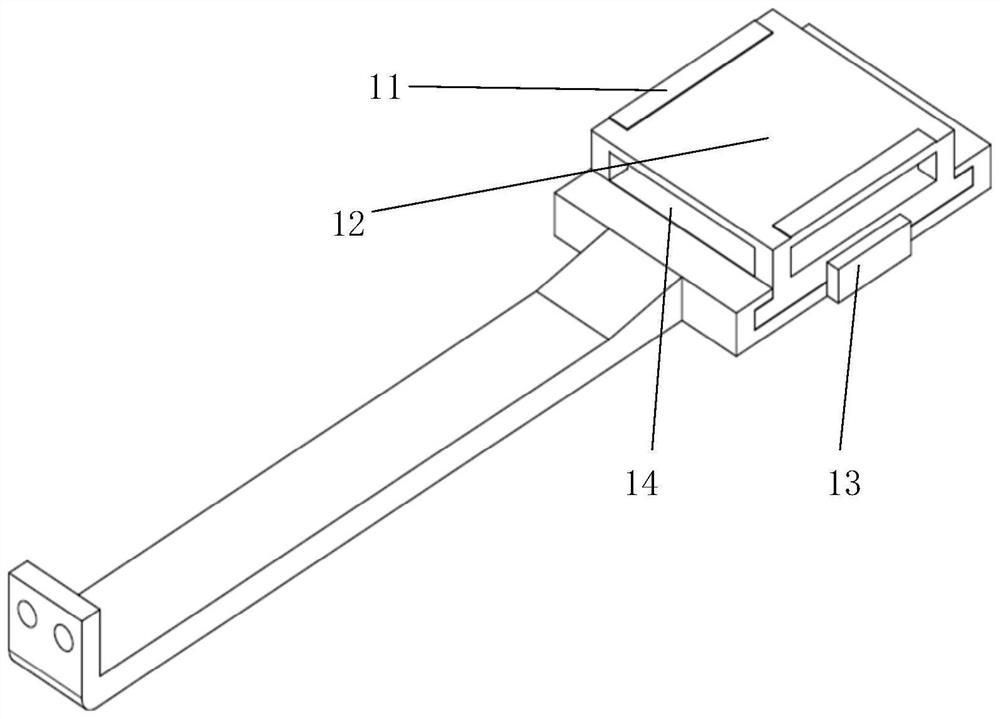

[0066] The parameters of the laser device were set as the wavelength of 1064 nm, the power of 30 W, and the scanning speed of 1 m / s. The regulated perovskite material is a strontium titanate single crystal with a size of 10*10*0.5 mm. First, the calibration sample is placed on the sample stage, and the aluminum wire is punched between the sample and the sample stage electrode by ultrasonic pressure welding technology. Then clamp the sample stage on the fixed rod, fix the fixed rod with the electrode plate, and calibrate the level. Use wires to connect the stage electrodes to the detachable electrode rods. The above steps are all carried out outside the vacuum box, then the electrode plate is connected and sealed with the vacuum box, the vacuum pump is turned on, and the vacuum gauge shows that the air pressure in the chamber is 3.3×10 -7 Torr, you can use the quartz observation window to observe the sample condition in the cavity.

[0067] Place the vacuum box under the lase...

Embodiment 2

[0070] The parameter setting and experimental operation steps of the laser device are roughly the same as those in Example 1, the difference is that there are two aluminum wire loops on the sample to compare the transport changes in the laser scanning and non-scanning regions.

[0071] The control material is the strontium titanate superlattice Ruddlesden-Popper (RP) phase epitaxially grown on the strontium titanate substrate. Due to the existence of the superlattice phase interface, the RP phase is more difficult to generate oxygen vacancies than the single crystal phase. It is easier to fill when the oxygen vacancies are filled. Using this feature, the RP phase on the surface can be filled first to block the channel and then retain the bulk oxygen vacancies in the lower layer, so that the conductivity can be retained, and the first half of the transport curve The section is the same as in Example 1. After the laser is turned off, the resistance of the material rises slowly bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| laser power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com