Self-sintering nano-copper soldering paste and preparation method and use method thereof

A nano-copper, self-sintering technology, applied in welding equipment, manufacturing tools, welding media, etc., can solve the problems of limiting the application of copper nanoparticles, poor sintered body performance, long sintering time, etc., to shorten the chemical reaction time and sintering performance. Good, short chemical reaction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A self-sintered nano copper solder paste in the present embodiment, the preparation method thereof and the method of use thereof:

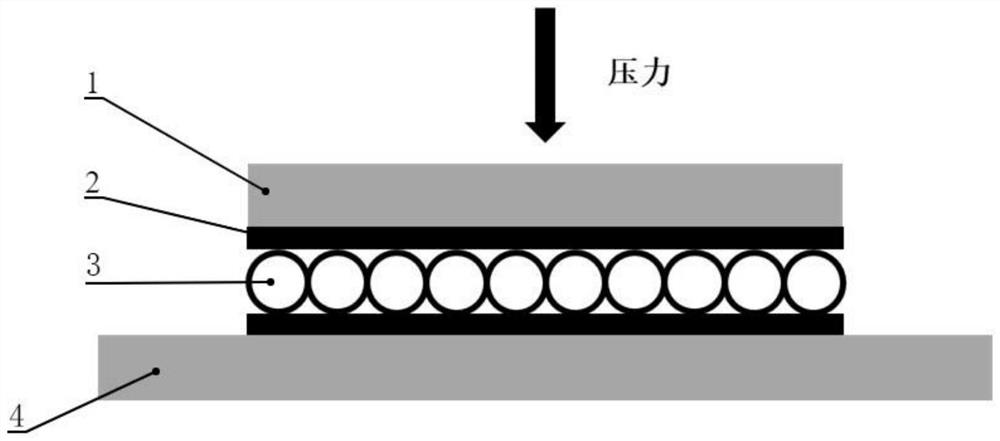

[0030]Weigh 50mmol of copper chloride dissolved in a flask containing 20ml of water, the flask is heated in an oil bath, so that the solution temperature is maintained at 90 ° C, 0.96mg of citric acid and 0.76mg of sodium hypophosphite are added to the flask, and after 15min of the reaction, centrifugal cleaning can obtain citric acid-coated CuNPs. Mix CuNPs with ethanol to obtain a copper paste by mixing it with ethanol in a volume ratio of 90:10. The aqueous solutions of 2% sodium alginate, 1% OP-10 and 35% aqueous ammonia were uniformly obtained to obtain a burn aid. On the substrate 4 and the back of chip 1 using screen printing co-firing agent and drying, and then on the substrate 4 of the co-firing agent printed a layer of copper paste and dried, chip 1, the burner layer 2, nano copper particle layer 3, substrate 4 four position diagram a...

Embodiment 2

[0032] A self-sintered nano copper solder paste in the present embodiment, the preparation method thereof and the method of use thereof:

[0033] Weigh 50mmol of copper chloride dissolved in a flask containing 20ml of water, the flask is heated in an oil bath, so that the solution temperature is maintained at 90 ° C, 0.96mg of citric acid and 0.76mg of sodium hypophosphite are added to the flask, and after 15min of the reaction, centrifugal cleaning can obtain citric acid-coated CuNPs. Mix CuNPs with ethanol in volume ratio 85:15 to obtain copper paste. The aqueous solution of 1% o-hydroxybenzoic acid, 1% OP-10 and 30% hydrazine hydrate was uniformly obtained to obtain a burn aid. On the substrate 4 and the back of chip 1 using screen printing co-firing agent and drying, and then on the substrate 4 of the co-firing agent printed a layer of copper paste and dried, chip 1, the burner layer 2, nano copper particle layer 3, substrate 4 four position diagram as attached Figure 1 As sho...

Embodiment 3

[0035] A self-sintered nano copper solder paste in the present embodiment, the preparation method thereof and the method of use thereof:

[0036] Weigh 50mmol of copper chloride dissolved in a flask containing 20ml of water, the flask is heated in an oil bath, so that the solution temperature is maintained at 90 ° C, 0.96mg of citric acid and 0.76mg of sodium hypophosphite are added to the flask, and after 15min of the reaction, centrifugal cleaning can obtain citric acid-coated CuNPs. Mix CuNPs with ethanol in volume ratio 85:15 to obtain copper paste. The aqueous solution of 3% acrylic resin, 1% EP-10 and 50% ethylenediamine was homogeneous to obtain a burn aid. On the substrate 4 and the back of chip 1 using screen printing co-firing agent and drying, and then on the substrate 4 of the co-firing agent printed a layer of copper paste and dried, chip 1, the burner layer 2, nano copper particle layer 3, substrate 4 four position diagram as attached Figure 1 As shown, the mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com