Power gain type black photovoltaic backboard

A photovoltaic backplane, gain-type technology, applied in the field of solar cells, can solve the problems of power increase and difficulty, and achieve the effect of increasing the utilization rate, improving the reflection function, and increasing the heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

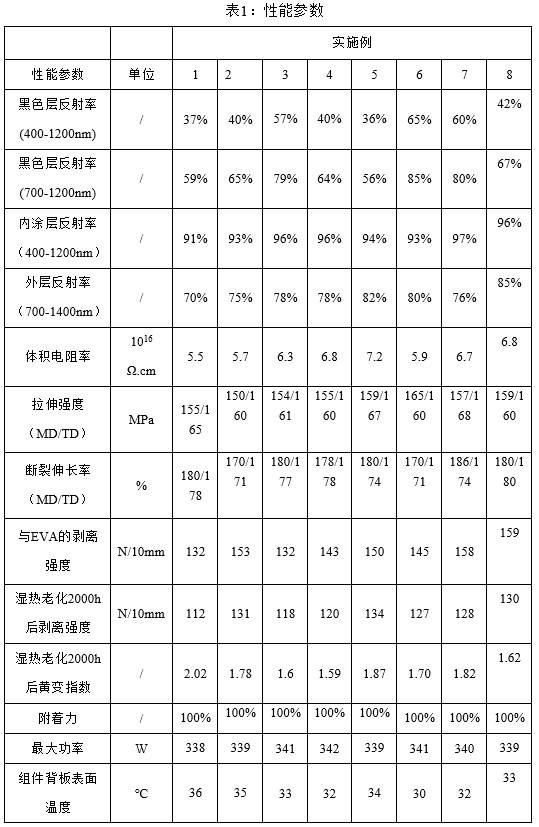

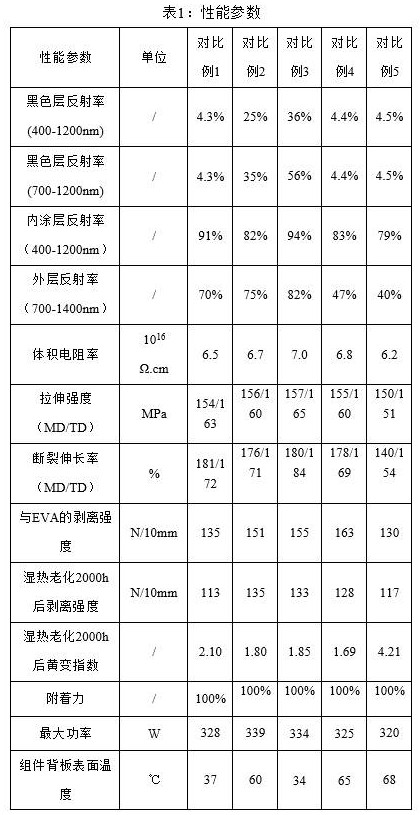

Examples

Embodiment 1

[0030] A power-gaining black photovoltaic backplane is composed of a grid-shaped black layer, an inner coating, a support layer and an outer layer in turn from the inside to the outside. The black layer is located in the cell gap.

[0031] Wherein, the black layer has a thickness of 2-60 µm, and is composed of 70% of resin A, 5% of filler A, 24% of filler B, 0.5% by weight of curing agent A, and 0.5% of auxiliary agent.

[0032] The resin A is selected from acrylic resins.

[0033] The filler A is selected from iron-chromium black with an average particle size of 0.05-20 μm.

[0034] The filler B is selected from glass microbeads with an average particle size of 0.1-100 μm.

[0035] The curing agent A consists of a hexamethylene diisocyanate trimer with a mass fraction of 70% and a diazepine compound with a mass fraction of 30%.

[0036] The inner coating has a thickness of 2-30 µm, and is composed of 95% of resin A, 1% of filler C, 3% of curing agent B, and 1% of auxiliary...

Embodiment 2

[0047] A power-gaining black photovoltaic backplane is composed of a grid-shaped black layer, an inner coating, a supporting layer and an outer layer in turn from the inside to the outside. The grid-like black layer is located in the cell gap.

[0048] Wherein, the grid-like black layer has a thickness of 2-60 µm, and is composed of 60% resin A, 5.5% filler A, 22% filler B, 12wt% curing agent A, and 0.5% auxiliary agent. .

[0049] The resin A is selected from epoxy resins.

[0050] The filler A is selected from copper-chromium black with an average particle size of 0.05-20 μm.

[0051] The filler B is selected from ceramic microbeads with an average particle size of 0.1-100 μm.

[0052] The curing agent A consists of a hexamethylene diisocyanate trimer with a mass fraction of 80% and a fused-ring aromatic amine compound with a mass fraction of 20%.

[0053] The inner coating has a thickness of 2-30 µm, and is composed of 80% resin A, 10% filler C, 9wt% curing agent B, and...

Embodiment 3

[0064] A power-gaining black photovoltaic backplane is composed of a grid-shaped black layer, an inner coating, a supporting layer and an outer layer in turn from the inside to the outside. The grid-like black layer is located in the cell gap.

[0065] Wherein, the thickness of the grid-like black layer is 2-60 µm, and is composed of 90% resin A, 4% filler A, 5% filler B, 0.5% curing agent A, and 0.5% auxiliary agent.

[0066] The resin A is selected from fluorocarbon resin chlorotrifluoroethylene-vinyl ether.

[0067] The filler A is selected from perovskite manganese black with an average particle size of 0.05-20 μm.

[0068] The filler B is selected from ceramic microbeads and pearlescent powders with an average particle size of 0.1-100 μm.

[0069] The curing agent A consists of isophorone diisocyanate trimer with a mass fraction of 75% and an azabenzene compound with a mass fraction of 25%.

[0070] The inner coating has a thickness of 2-30 µm, and is composed of 71% r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com