Flame-retardant self-repairing waterborne polyurethane composite coating agent as well as preparation method and application thereof

A water-based polyurethane, self-healing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of poor flame retardancy, low mechanical strength, limited life of paint film protection, etc. Mechanical properties, the effect of promoting self-healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

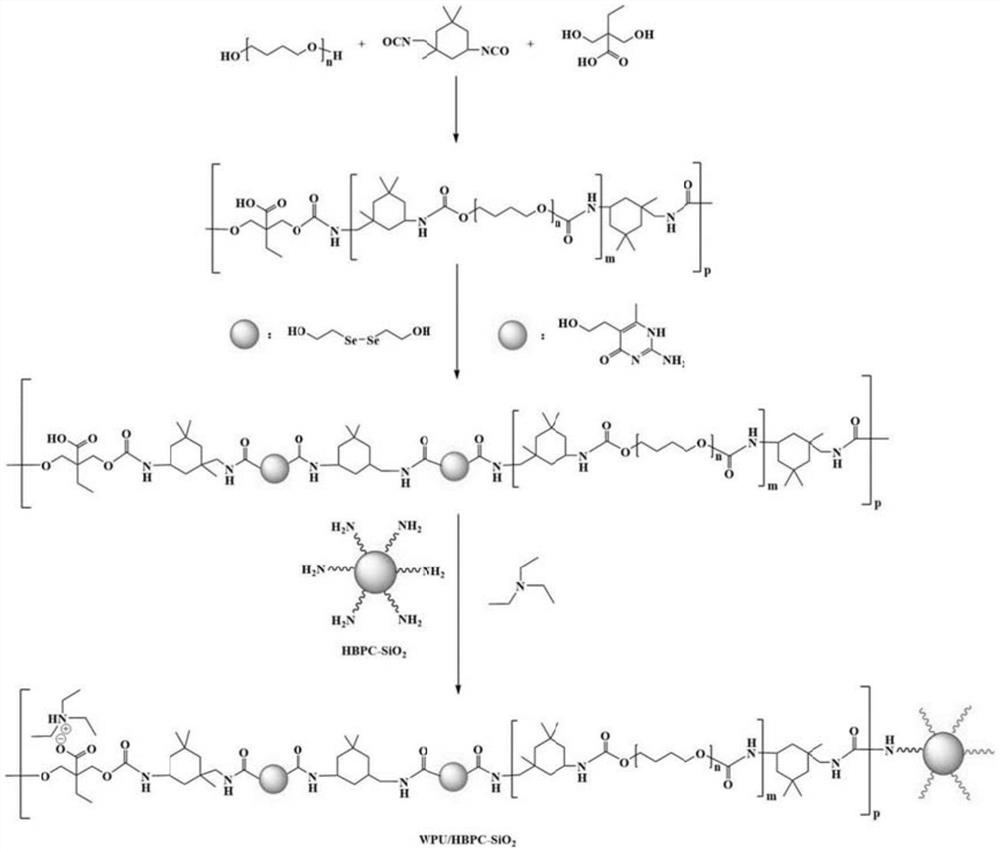

[0035] The invention discloses a method for preparing a flame-retardant self-repairing water-based polyurethane composite coating agent. The process steps are as follows:

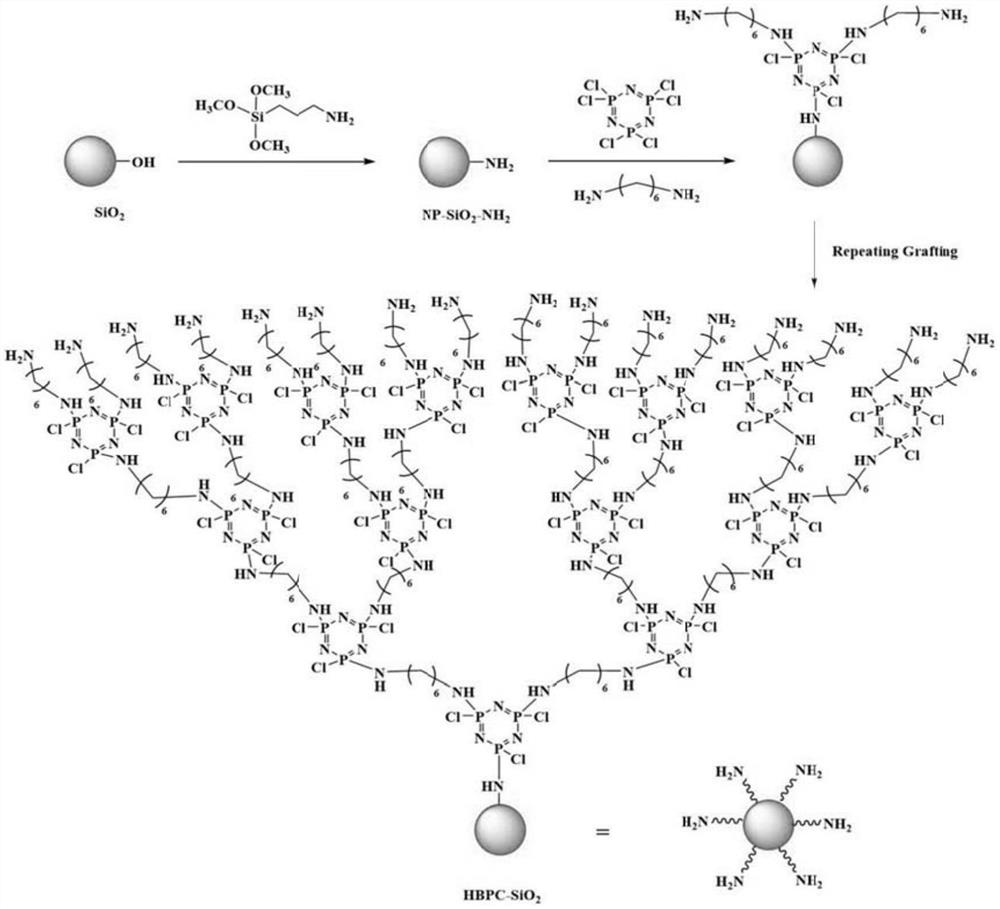

[0036] 1. Preparation of amino-terminated hyperbranched polyphosphazene modified nanoparticles (HBPC)

[0037] 1) Ultrasonic disperse 0.1-10 parts of nanoparticles in 50-1000 parts of water / ethanol mixed solution, slowly add 0.01-2 parts of coupling agent, at a speed of 300-500r / min, and a reaction temperature of 60-80°C Under the conditions of reaction for 5-8h, after the completion of the reaction, centrifuge washing with deionized water and absolute ethanol, and then vacuum-dry to obtain aminated nanoparticles (NP-NH 2 );

[0038] Wherein, the nanoparticles are nano silicon dioxide (SiO 2 ), nano-titanium dioxide (TiO 2 ), graphene oxide (GO), hydrotalcite (LDH), montmorillonite (MMT), two-dimensional metal-organic framework film (MOF) and nano-magnesium hydroxide (MH); the particles of the nanopartic...

Embodiment 1

[0055] 1. Amino-terminated hyperbranched polyphosphazene modified nano-silica (HBPC-SiO 2 ) preparation

[0056] 1) Mix 1 part of 50nm silicon dioxide (SiO 2 ) ultrasonically dispersed in 100 parts of water / ethanol mixed solution, slowly add 0.01 part of 3-aminopropyltrimethoxysilane as a coupling agent, react at 74°C for 6 hours at a speed of 300r / min, and use deionized water after the reaction is completed Centrifugal washing with absolute ethanol, and then vacuum drying to obtain aminated nano-silica (NP-SiO 2 -NH 2 );

[0057] 2) Add 0.1 part of NP-SiO 2 -NH 2 Add to 50 parts of tetrahydrofuran solution, add a total of 5 parts of hexachlorocyclotriphosphazene and 1,6-hexanediamine according to a feed ratio of 1:4; add 0.5 parts of triethylamine as an acid-binding agent, Feed nitrogen and react at a speed of 300r / min and a temperature of 65°C for 6h to obtain amino-terminated hyperbranched polyphosphazene-modified nano-silica (HBPC-SiO 2 );

[0058] 2. HBPC-SiO with...

Embodiment 2

[0064] 1. Amino-terminated hyperbranched polyphosphazene modified nano-silica (HBPC-SiO 2 ) preparation

[0065] 1) Two parts of 1000nm silicon dioxide (SiO 2 ) ultrasonically dispersed in 200 parts of water / ethanol mixed solution, slowly add 0.02 parts of 3-aminopropyltriethoxysilane as a coupling agent, and react at 70°C for 7 hours at a speed of 300r / min. After the reaction is completed, use a deionized Centrifugal washing with water and absolute ethanol, and then vacuum drying to obtain aminated nano-silica (NP-SiO 2 -NH 2 );

[0066] 2) Add 0.1 part of NP-SiO 2 -NH 2 Join in 50 parts of tetrahydrofuran solutions, add a total amount of 8 parts of hexachlorocyclotriphosphazene and 1,8-octanediamine at a feed ratio of 3:5; add 0.8 parts of triethylamine as an acid-binding agent, and Into nitrogen and at a rotating speed of 500r / min and a temperature of 70°C, react for 6h to obtain amino-terminated hyperbranched polyphosphazene-modified nano-silica (HBPC-SiO 2 );

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com