Preparation method of polysiloxane modified super-hydrophobic sponge for oil-water separation

A technology for superhydrophobic sponge and oil-water separation, applied in the field of preparation of polysiloxane modified superhydrophobic sponge, can solve the problems of reduced heat resistance and mechanical stability of sponge, and achieve excellent thermal stability, strong adsorption capacity, Good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] The melamine sponge was cut into 2×2×2 cm blocks, washed with deionized water and ethanol several times and dried for later use. Dissolve 0.5g of hydroxyl-terminated polydimethylsiloxane, 0.1g of tetraethylorthosilicate and 0.02g of dibutyltin dilaurate in 15g of n-hexane, and add 0.18g of hydrophobic gas-phase nano-SiO 2 , after ultrasonic dispersion for 10min, stir on a magnetic stirrer for 60min to obtain PDMS / SiO 2 compound solution. Submerge the pretreated sponge completely in PDMS / SiO 2 In the composite solution, take it out after 30 minutes, and after curing and drying in an oven at 55°C, you can get PDMS / SiO 2 Modified sponge.

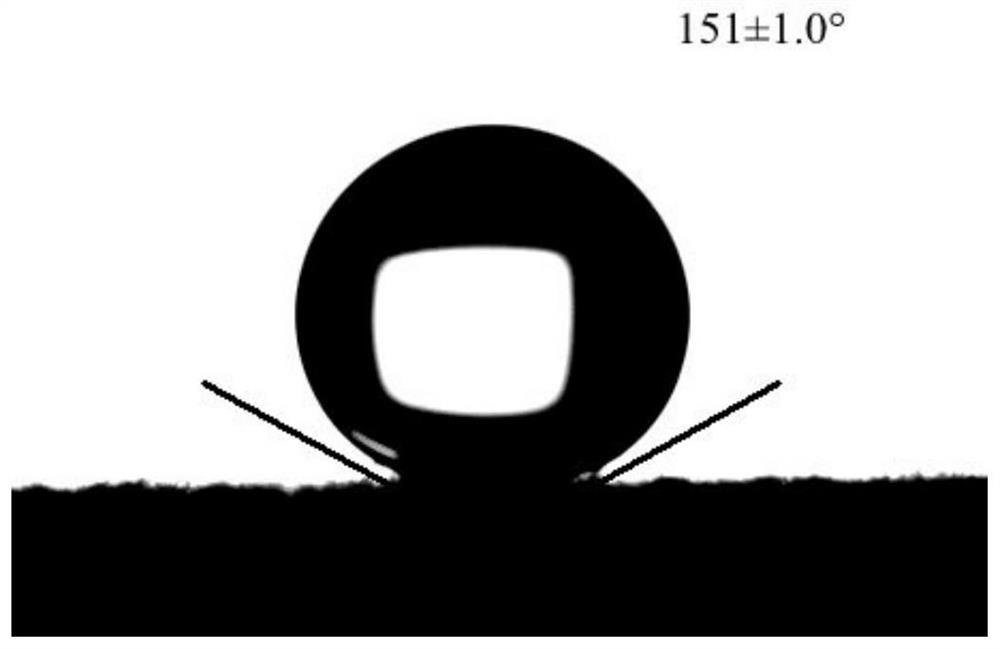

[0053] The modified sponge prepared according to Example 1 is tested by a contact angle tester, and the average water contact angle is 151 ± 1.0 ° ( figure 1 ), it can be seen that the modified sponge has excellent hydrophobicity.

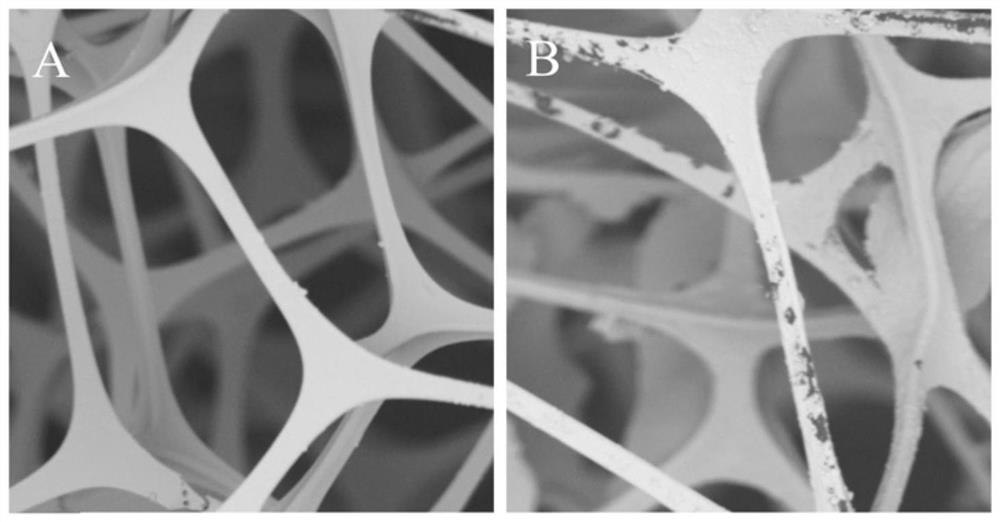

[0054] According to the scanning electron micrograph of the modified sponge prepared in Example 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com