Composite electrolyte based on porous organic compound and preparation method and application thereof

An organic compound and composite electrolyte technology, applied in the field of electrochemistry, can solve the problems of narrow electrochemical window, difficult in-situ composite, easy agglomeration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

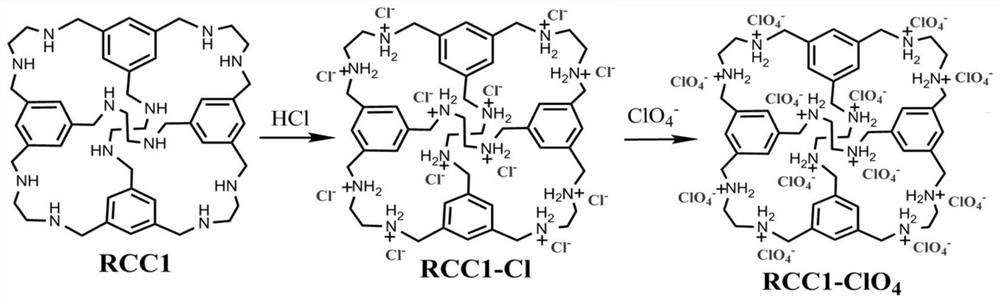

[0056] 1 g of laboratory prepared polyamine macrocyclic porous organic compound RCC1 powder was dissolved in 10 mL of chloroform. 3mL of commercially available 4M hydrochloric acid / dioxane solution was added dropwise to the above solution to obtain a white precipitate RCC1-Cl. After the precipitate was washed, 10mL of 10% mass fraction of lithium perchlorate-ethanol solution was added, and heated and stirred. The lithium perchlorate-ethanol solution was replaced twice in the middle to obtain RCC1-ClO 4 . The porous organic compound RCC1-ClO 4 The specific preparation process of figure 1 shown.

Embodiment 2

[0058] 5 mg of laboratory prepared RCC1-ClO 4 Dissolve in 2 mL of methanol to give solution 1. Polyethylene oxide (PEO) and LiClO 4 Dissolve in acetonitrile at a molar ratio of 8:1 to give solution 2, in which PEO and LiClO 4 The total weight accounts for 10wt%. Mix solution 1 and solution 2 in a glass bottle by magnetic stirring (where RCC1-ClO 4 The mass fraction of 5wt% PEO / LiClO 4 The mass fraction of 95 wt%), a uniformly mixed composite electrolyte solution based on porous organic compounds was obtained after 12 h. Then, the mixed solution was cast into the small round hole of the PTFE mold, and the thickness of the electrolyte membrane could be controlled according to the different amount added, and it was vacuum-dried at 60°C and then stored in an argon glove box. One week to remove the residual solvent or trace water in the membrane to obtain a porous organic compound solid-state composite electrolyte membrane.

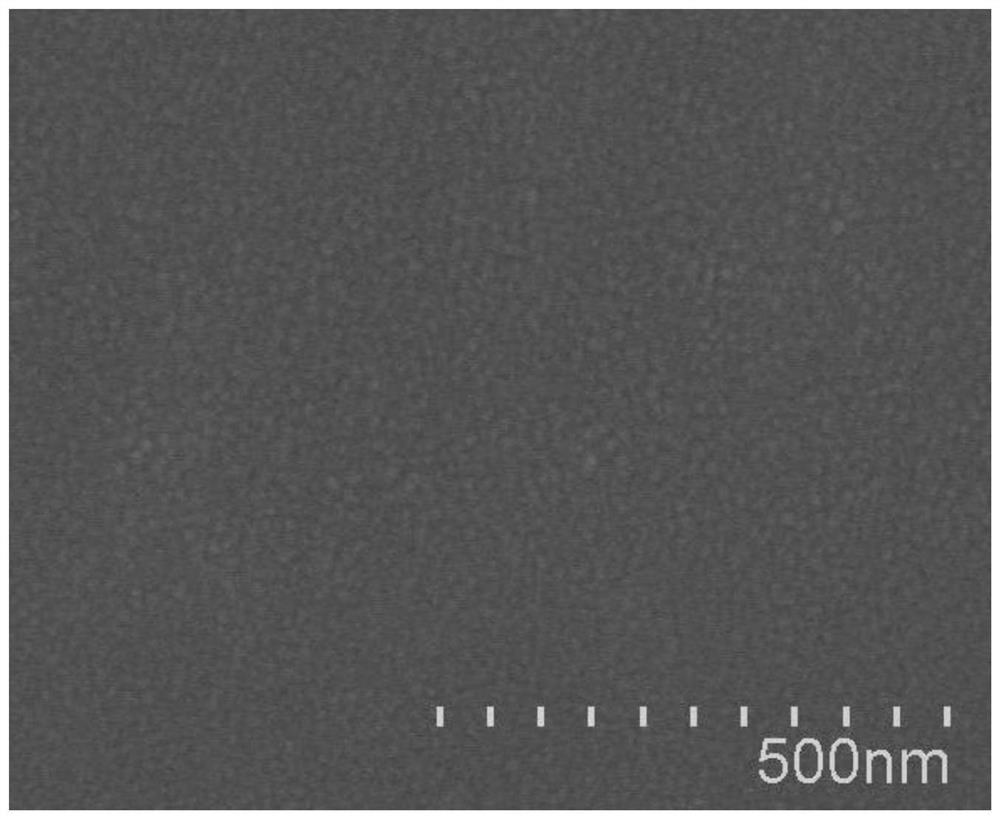

[0059] The SEM morphology of the composite electro...

Embodiment 3

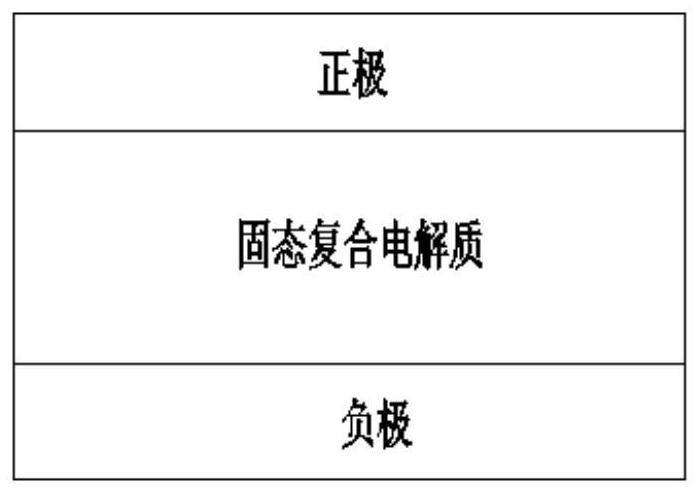

[0061] Lithium iron phosphate powder: AB (acetylene black): PVDF was dispersed in N-methylpyrrolidone (NMP) in a mass ratio of 92:5:3 to obtain a solid-state battery positive electrode slurry. The positive electrode was obtained after the positive electrode slurry was coated and dried, and then the composite electrolyte solution based on the porous organic compound of Example 2 was coated on the surface of the positive electrode. After drying, it was assembled with the lithium negative electrode to form a solid-state battery, which was heated and melted at 70 °C for 24 hours. Part of the electrolyte penetrates into the positive electrode for ion conduction. The solid-state battery has good cycle performance at 70 °C, and the cycle performance of the battery is shown in the figure below. Image 6 and 7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com