Protein-based magnetic agarose porous microspheres and preparation method thereof

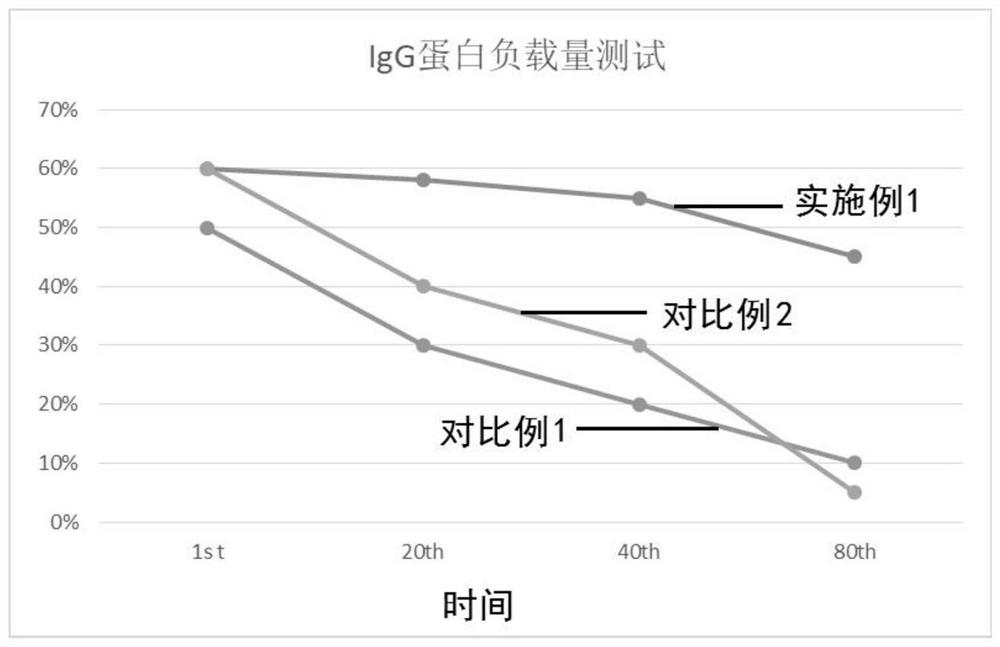

A technology of agarose microspheres and agarose, applied in the field of magnetic agarose porous microspheres and its preparation, can solve the problems of long retention time of IgG and poor alkali resistance, achieve good anti-oxidation and alkali resistance, and improve alkali resistance , the effect of increasing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A protein-based magnetic agarose porous microsphere and a preparation method thereof, specifically comprising the following steps:

[0029] 1. Pass 13.74g Fe 2 SO 4 ·7H 2 O, 24g FeCl 3 ·6H 2 O, 100 g water, room temperature N 2 Pass 20min, add 50gNH 3 ·H 2 O, stirred at room temperature for 2h to obtain nano Fe 3 O 4 .

[0030] 2. Take the above nano Fe 3 O 4 10 g, add 100 mL of ethanol, 2 mL of ammonia water, 2 g of TEOS, and stir at room temperature for 24 h to obtain silanol-modified Fe 3 O 4 .

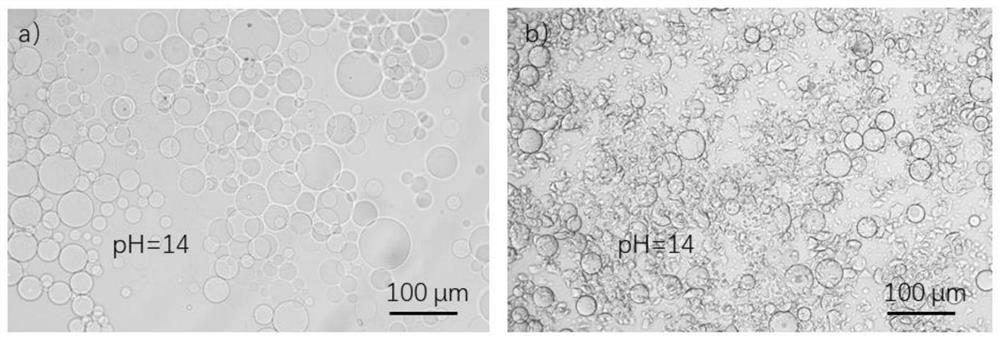

[0031] 3. The above-mentioned silanol modified Fe 3 O 4 10 g was heated to 65 ℃, added 10 mL of 4% mass concentration agarose aqueous solution at 65 ℃, 30 g of paraffin oil at 65 ℃ and 1 g of Tween 20, and stirred at 500 rpm for 20 min. The temperature was lowered to 25°C to obtain magnetic agarose microspheres.

[0032] 4. Add 10 g of the above microspheres to 2 g of propylene glycol diglycidyl ester, add 800 μL of 48% NaOH, and react at 50° C. for 16 h to ...

Embodiment 2

[0036] A protein-based magnetic agarose porous microsphere and a preparation method thereof, specifically comprising the following steps:

[0037] 1. Pass 13.74g Fe 2 SO 4 ·7H 2 O, 24g FeCl 3 ·6H 2 O, 100 g water, room temperature N 2 Pass 20min, add 50gNH 3 ·H 2 O, stirred at room temperature for 2h to obtain nano Fe 3 O 4 .

[0038] 2. Take the above nano Fe 3 O 4 10 g, add 100 mL of ethanol, 2 mL of ammonia water, 2 g of TEOS, and stir at room temperature for 24 h to obtain silanol-modified Fe 3 O 4 .

[0039] 3. The above-mentioned silanol modified Fe 3 O 4 10 g was heated to 65 ℃, added 10 mL of 4% mass concentration agarose aqueous solution at 65 ℃, 30 g of cyclohexane at 65 ℃ and 1 g of Span 85, stirred at 500 rpm for 20 min, after the reaction was completed, at a rate of 5 ℃ / min The temperature was rapidly lowered to 25°C to obtain magnetic agarose microspheres.

[0040] 4. Add 10 g of the above microspheres to 2 g of propylene glycol diglycidyl ester,...

Embodiment 3

[0044] A protein-based magnetic agarose porous microsphere and a preparation method thereof, specifically comprising the following steps:

[0045] 1. Pass 13.74g Fe 2 SO 4 ·7H 2 O, 24g FeCl 3·6H 2 O, 100 g water, room temperature N 2 Pass 20min, add 50gNH 3 ·H 2 O, stirred at room temperature for 2h to obtain nano Fe 3 O 4 .

[0046] 2. Take the above nano Fe 3 O 4 10 g, add 100 mL of ethanol, 2 mL of ammonia water, 2 g of TEOS, and stir at room temperature for 24 h to obtain silanol-modified Fe 3 O 4 .

[0047] 3. The above-mentioned silanol modified Fe 3 O 4 10 g was heated to 65 ℃, added 10 mL of 4% mass concentration agarose aqueous solution at 65 ℃, 30 g of n-heptane at 65 ℃ and 1 g of Span 80, and stirred at 500 rpm for 20 min. After the reaction was completed, at a rate of 5 ℃ / min The temperature was rapidly lowered to 25°C to obtain magnetic agarose microspheres.

[0048] 4. Add 10 g of the above microspheres to 2 g of propylene glycol diglycidyl ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com