P-hydroxybenzoic acid production wastewater treatment system

A technology for the production of p-hydroxybenzoic acid and waste water, which is applied in natural water treatment, water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of inconsistent treatment process, unfavorable environmental sustainable development, inconvenient operation, etc. problems, to achieve the effect of improving adsorption efficiency, improving resource recycling rate, and reducing production recycling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

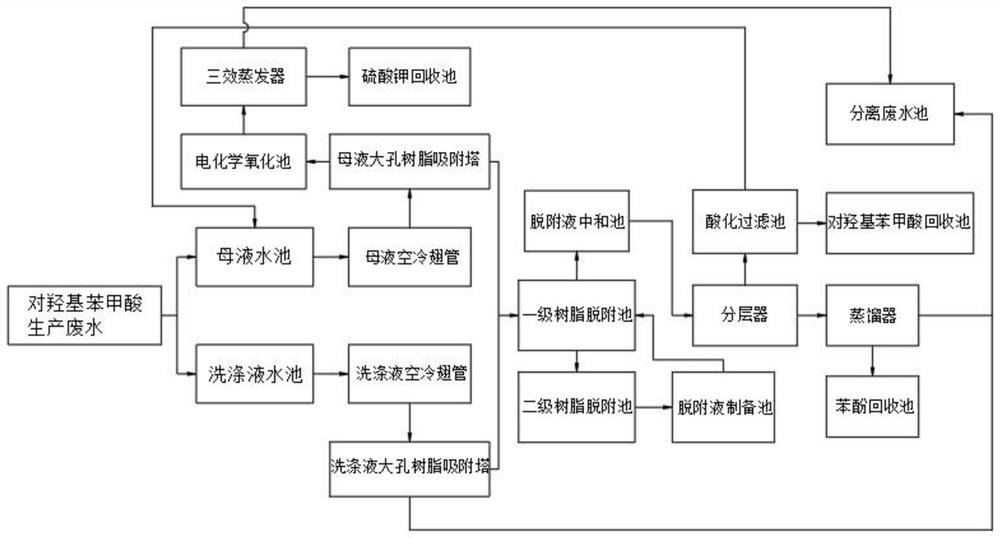

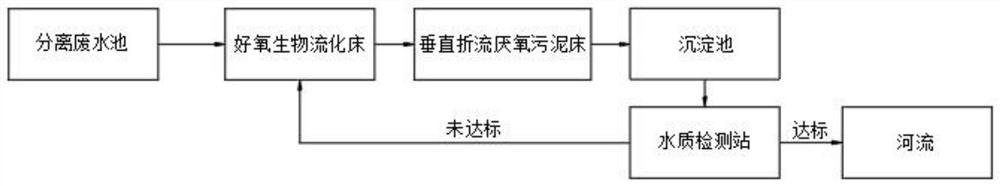

[0036] A p-hydroxybenzoic acid production wastewater treatment system, such as Figure 1-2 As shown, it includes p-hydroxybenzoic acid production wastewater, and the p-hydroxybenzoic acid production wastewater includes a mother liquor pool and a washing liquid pool. The mother liquor air-cooled finned tube is connected to the mother liquor macroporous resin adsorption tower, the mother liquor macroporous resin adsorption tower is connected to an electrochemical oxidation tank, the electrochemical oxidation tank is connected to a three-effect evaporator, and the three-effect evaporator is also connected to potassium sulfate In the recovery tank, the solid after the evaporation of the waste liquid is potassium sulfate, the washing liquid air-cooled fin tube is connected to the washing liquid macroporous resin adsorption tower, and the washing liquid macroporous resin adsorption tower and the mother liquor mother liquor macroporous resin adsorption tower are both connected The pr...

Embodiment 2

[0038]The mother liquor waste water produced in the production of p-hydroxybenzoic acid, the waste water temperature is 45 ℃, the appearance is yellow, the pH value is 2.5, the mother liquor waste water is first cooled to normal temperature by the mother liquor air-cooled fin tube, the COD in the filtrate is 10000, and the filtrate is at a temperature of 25 ℃ Under the condition of 10BV / hr flow rate, it passes through the mother liquor macroporous resin adsorption tower, the mother liquor macroporous resin adsorption tower collects the adsorption effluent COD below 100, and the effluent flows into the electrochemical oxidation tank to remove the slightly soluble phenol and p-hydroxybenzoic acid in the water, and then Potassium sulfate solid is obtained by evaporation in a three-effect evaporator. After 8 hours of adsorption by the mother liquor macroporous resin, the mother liquor macroporous resin is saturated with adsorption, and is eluted with 5% sodium hydroxide solution in ...

Embodiment 3

[0040] The washing liquid wastewater produced in the production of p-hydroxybenzoic acid, the temperature of the wastewater is 40 ° C, the appearance is light yellow, the pH value is 2.0, the washing liquid wastewater is first cooled to room temperature by the washing liquid air-cooled fin tube, the COD in the filtrate is 8000, and the filtrate is At a temperature of 25°C, the macroporous resin adsorption tower of the washing liquid is carried out at a flow rate of 10 BV / hr. The macroporous resin adsorption tower of the washing liquid collects the adsorbed effluent with COD below 100. The macroporous adsorption resin of the washing liquid is adsorbed and washed for 8 hours. The liquid macroporous resin is saturated with adsorption, and is eluted with 5% sodium hydroxide solution in the primary resin desorption tank. It is a high-concentration desorption solution, which is then eluted with pure water in the secondary resin desorption pool. The eluate after elution in the seconda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com