Method for preparing vinyl chloride through reaction of acetylene and hydrogen chloride

A technology of acetylene hydrochlorination and hydrogen chloride, which is applied in the addition preparation of hydrogen halide, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problem of no industrialization, catalyst activity stability cannot meet industrialization requirements, and catalyst catalytic reaction activity is improved. limited issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

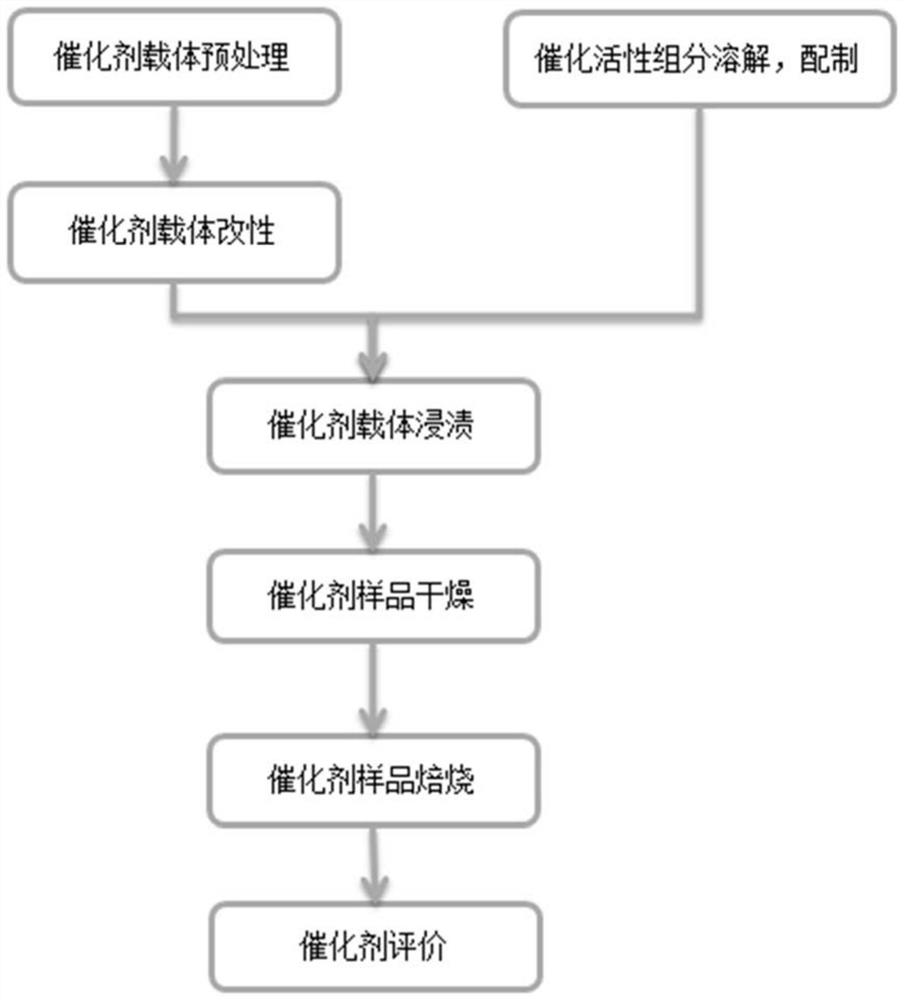

[0098] The following Examples 1-9 relate to the preparation of non-precious metal composite catalysts, unless otherwise specified, the main implementation steps include:

[0099] (1) subjecting the catalyst carrier to pretreatment under certain conditions to obtain a pretreated catalyst carrier;

[0100] (2) modifying the catalyst carrier treated in step (1) under certain conditions to regulate the surface groups of the carrier and improve the dispersion and fixation of the catalytically active components;

[0101] (3) preparing the catalytic active component metal salt solution in turn; the catalytic metal salt solution; the alkali metal salt solution; the rare earth metal salt solution; the coordination compound solution;

[0102] (4) mixing and impregnating the modified catalyst carrier in step (2) with each group of solutions obtained in step (3);

[0103] (5) The impregnated sample is dried and calcined to obtain a non-mercury catalyst for catalyzing the hydrochlorinatio...

Embodiment 1

[0105] (1) Weigh 10 g of 40-mesh activated carbon, pretreat it with 2N hydrochloric acid solution at 60°C for 4 hours, then wash with deionized water until pH is neutral, and then dry at 100°C for 10 hours before use.

[0106] (2) Mix the pretreated activated carbon with 2N nitric acid and ammonium chloride solution, control the mass ratio of nitrogen atom to activated carbon at 1:10, ultrasonically impregnate it at 50KHZ for 2 hours, and dry it at 110°C for 12 hours after ultrasonic impregnation. After 1 hour, it was placed in a tube furnace and calcined for 2 hours in a nitrogen atmosphere to obtain the modified activated carbon.

[0107] (3) Weigh MnCl 3 and PbCl 4 Mixture, control quality and activated carbon ratio at 1:10, add water to dissolve to obtain solution I; weigh appropriate amount of LiCl and LaCl 3 Control its mass ratio to activated carbon to 1:20, add water to dissolve to obtain solution II; weigh an appropriate amount of triethyl phosphite, control its mas...

Embodiment 2

[0111] (1) Weigh 10 g of 40-purpose activated carbon, pre-treat it with 2N nitric acid solution at 80°C for 3 hours, then wash with deionized water to neutral pH, then dry at 120°C for 5 hours for later use;

[0112] (2) Mix the pretreated activated carbon with acrylamide and ammonium sulfate solution, control the mass ratio of nitrogen and sulfur atoms to the activated carbon mass at 1:5, ultrasonically impregnate it at 70KHZ for 4 hours, and dry it at 130°C after ultrasonic impregnation. After 8 hours, it was placed in a tube furnace, and calcined under nitrogen atmosphere for 2 hours to obtain modified activated carbon;

[0113] (3) Weigh TiCl 3 and IrCl 3 Mixture, control quality and activated carbon ratio at 1:20, add water to dissolve to obtain solution I; weigh an appropriate amount of BaCl 2 and LaCl 3 Control its mass ratio to activated carbon to 1:30, add water to dissolve to obtain solution II; weigh an appropriate amount of triphenylphosphorus, control its mass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com