Method for preparing polyethylene glycol/silicon dioxide composite shape-stabilized phase change energy storage material and product thereof

A polyethylene glycol and silica technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high raw material cost, complex production process and high production cost, and achieve the effect of reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

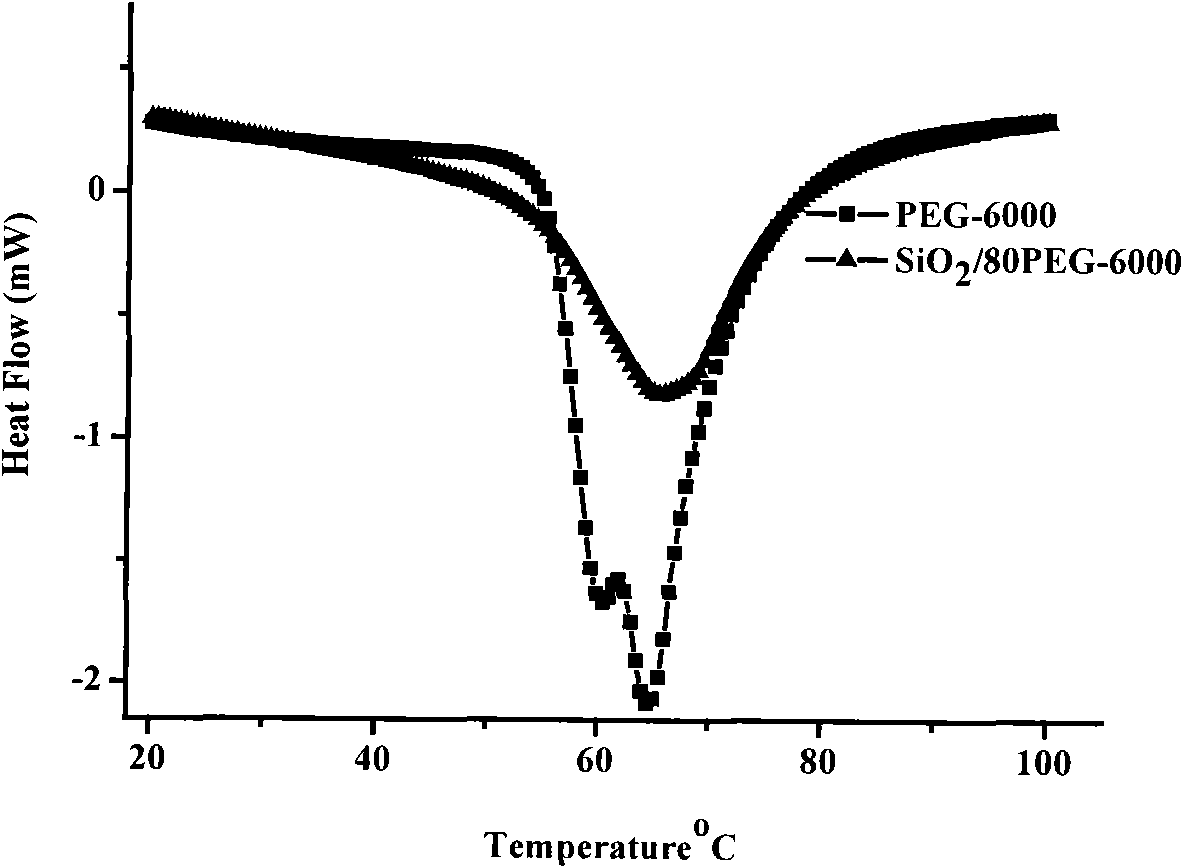

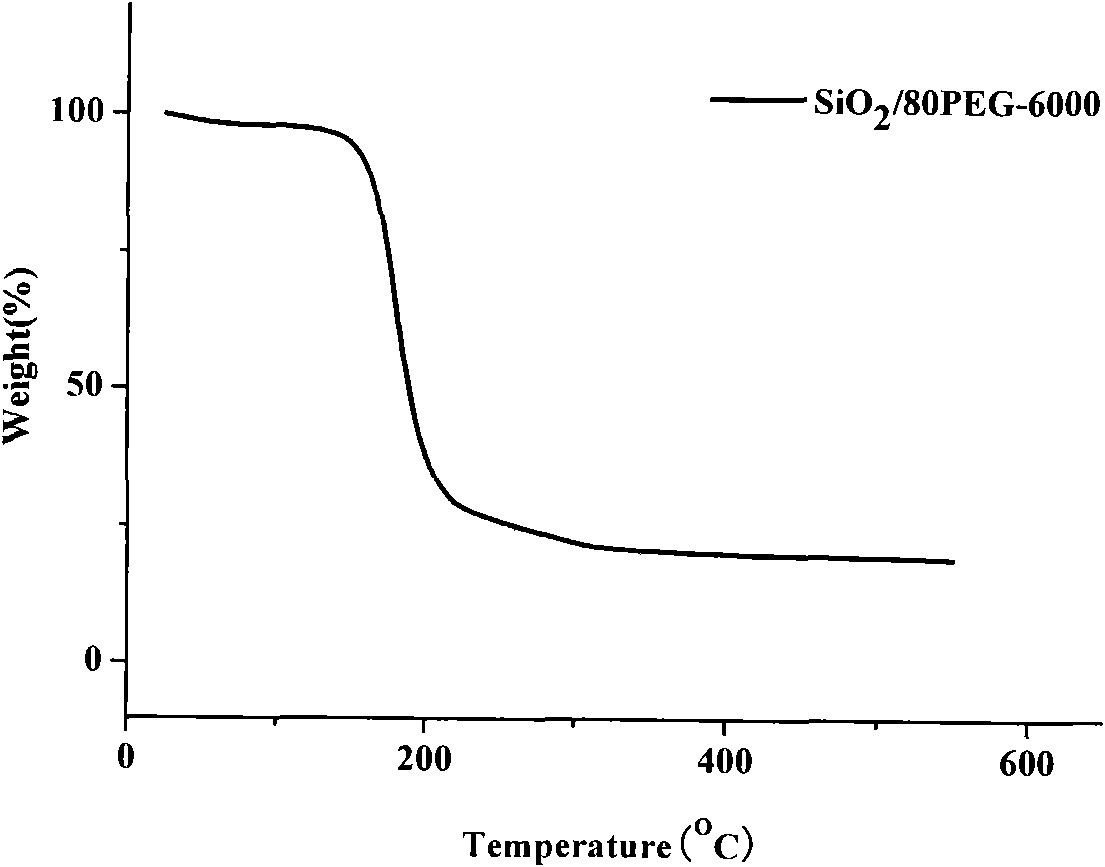

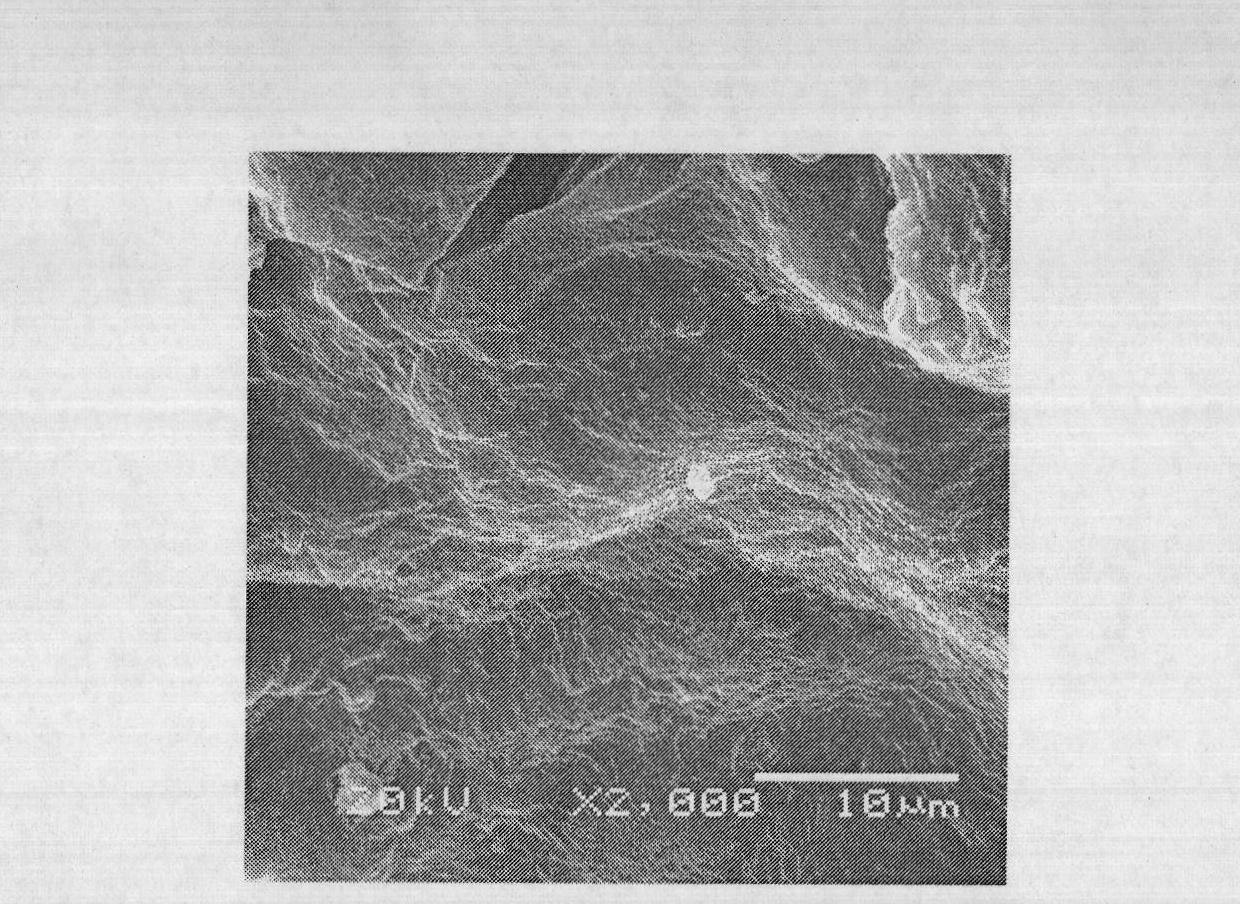

[0024] Steps: (1) Dissolve 12.0g PEG-6000 in 15.0ml water at room temperature to obtain a polyethylene glycol solution, and slowly add polycrystalline silicon production by-product SiCl dropwise under stirring with a magnetic stirrer 4 5.73ml, to make the whole gel. Take the gel out and place it in a watch glass, put the watch glass into a blast drying oven, and dry it to constant weight at 80°C to obtain a xerogel. Take out the xerogel, mash it in a mortar, and then Transfer to a watch glass and pulverize with a powerful mechanical pulverizer to obtain a powder. (2) Put the powder into a vacuum drying oven and vacuum-dry it at 40°C for 2.5 hours, further remove water and hydrogen chloride, and then put the powder into a container equipped with a stirrer, nitrogen pipe, reflux pipe, and dropping funnel In a 250ml four-necked bottle, under the protection of nitrogen, add the silane coupling agent KH-550 dropwise at a rate of 0.5% of the total powder weight at 80°C. After surfa...

Embodiment 2

[0026] Steps: (1) Dissolve 17.0g PEG-20000 in 17.0ml water at room temperature to obtain a polyethylene glycol solution, and slowly add polysilicon production by-product SiCl dropwise under stirring with a magnetic stirrer 4 5.74ml, to make the whole gel. Take the gel out and place it in a watch glass, put the watch glass into a blast drying oven, and dry it to constant weight at 80°C to obtain a xerogel. Take out the xerogel, mash it in a mortar, and then Transfer to a watch glass and pulverize with a powerful mechanical pulverizer to obtain a powder. (2) Put the powder into a vacuum drying oven and vacuum-dry it at 40°C for 2.0 hours to further remove water and hydrogen chloride, then put the powder into a container equipped with a stirrer, a nitrogen pipe, a return pipe, and a dropping funnel In a 250ml four-necked bottle, under the protection of nitrogen, add the silane coupling agent KH-560 dropwise at a rate of 0.1% of the total powder weight at 80°C. After surface modi...

Embodiment 3

[0028] Steps: (1) Dissolve 14.0g PEG-10000 in 20.0ml water at room temperature to obtain a polyethylene glycol solution, and slowly add polysilicon production by-product SiCl dropwise under stirring with a magnetic stirrer 4 11.5ml to make the whole gel. Take the gel out and place it in a watch glass, put the watch glass into a blast drying oven, and dry it to constant weight at 80°C to obtain a xerogel. Take out the xerogel, mash it in a mortar, and then Transfer to a watch glass and pulverize with a powerful mechanical pulverizer to obtain a powder. (2) Put the powder into a vacuum drying oven and vacuum-dry it at 40°C for 3.0 hours to further remove water and hydrogen chloride, then put the powder into a container equipped with a stirrer, nitrogen pipe, reflux pipe, and dropping funnel In a 250ml four-necked bottle, under the protection of nitrogen, add the silane coupling agent KH-570 dropwise at a rate of 0.3% of the total powder weight at 80°C. After surface modificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com