Production method of high thermal conductivity and insulation graphene for high polymer material and graphene

A technology of insulating graphene and polymer materials, applied in graphene, chemical instruments and methods, climate sustainability, etc., can solve problems such as limited application scenarios, increased electrical conductivity, and reduced polymer composite electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

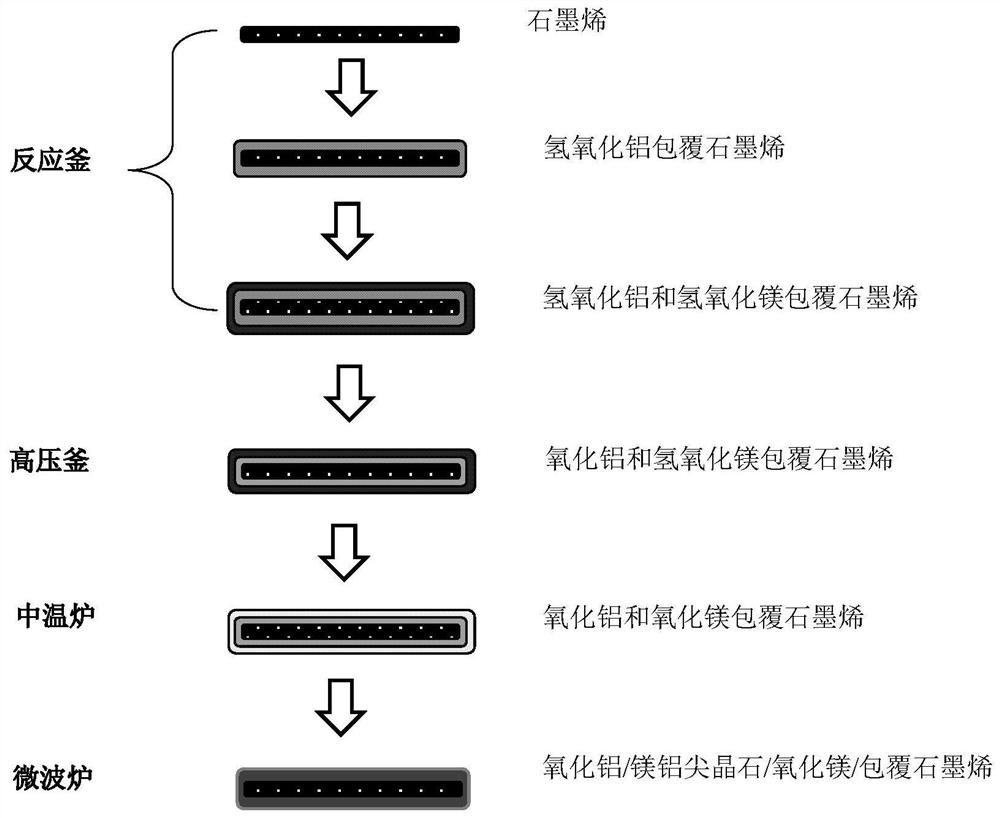

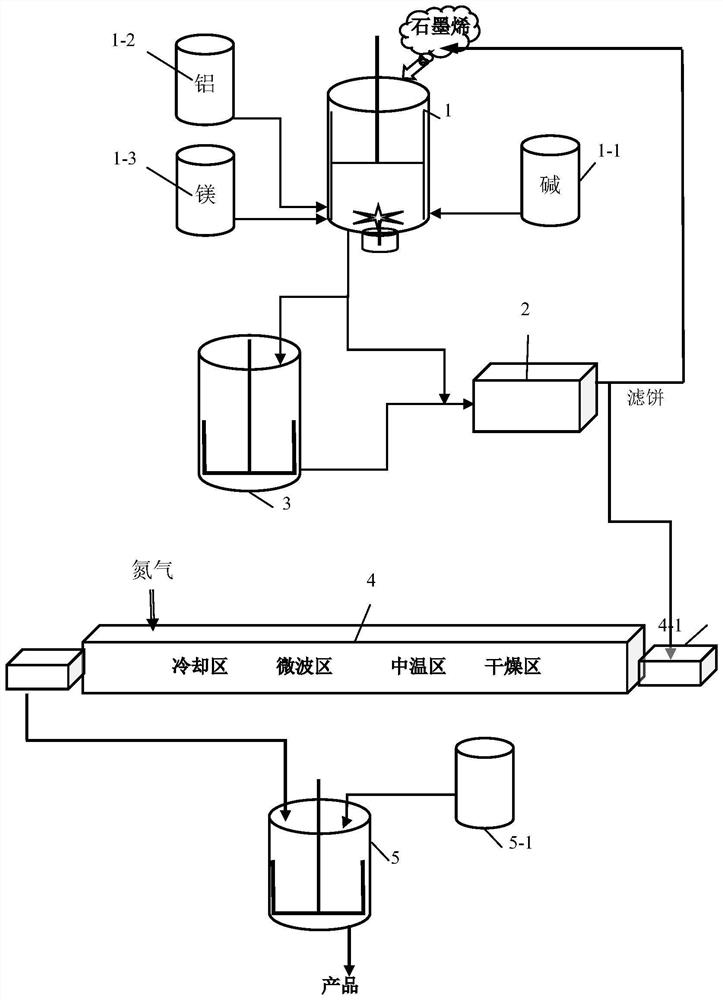

[0057] The preparation method of the high thermal conductivity insulating graphene for polymer materials provided by the application comprises the following steps:

[0058] a) Take graphene oxide as raw material, disperse it in deionized water, and obtain uniformly dispersed graphene oxide slurry through high energy and high shear dispersion;

[0059] b) Dissolving soluble aluminum salt, magnesium salt and alkali in deionized water to obtain an acid-base solution, and stirring and mixing silane coupling agent, deionized water, acetic acid and ethanol to form a silane coupling agent reaction solution;

[0060] c) the graphene oxide slurry is pumped into the acid and alkali-resistant reaction kettle, and the reaction kettle has stirring and jacket temperature control; continuous stirring, pH and temperature sensors are arranged in the kettle, and the alkaline solution is pumped to pH 6~9, preferably pH7~8, the temperature in the kettle is 20~40℃;

[0061] d) Continue stirring w...

Embodiment 1

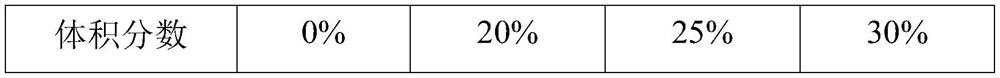

[0084] A method for preparing high thermal conductivity and insulating graphene for phenolic resin, which can be applied to LED lamp housings, the details are as follows:

[0085] [1] Select graphene oxide powder with a specific surface area of 150-300 m2 / g, a particle size of 10-30 μm, and an oxygen content of 5-10% prepared by electrolysis. Disperse it in deionized water with a mass concentration of 1-5.5wt%; magnesium nitrate and aluminum nitrate are respectively dissolved in deionized water and ammonia water is added, and the mass fractions of magnesium nitrate, aluminum nitrate and ammonia water are respectively 3-10wt%, 3-10wt%, and 10-20wt%.

[0086] [2] Add silane coupling agent KH550 to the mixture of ethanol and water, stir, and hydrolyze for 0.5-1.5 hours to obtain a silane coupling agent solution. The ratio of ethanol: silane coupling agent: water is 100:3 by mass. ~10:10~30.

[0087] [3] The graphene oxide slurry obtained in step [1] is pumped into the acid and...

Embodiment 2

[0100] A kind of high thermal conductivity insulating graphene powder for epoxy resin for PCB circuit board

[0101] [1] The graphene oxide with a particle size of 10 μm is treated at a high temperature of 200-300 ° C, its specific surface area is 200-380 m2 / g, and the oxygen content is 5-8%, and it is uniformly dispersed in deionized water. The weight ratio concentration in deionized water is 1-3%; magnesium sulfate and aluminum sulfate are respectively dissolved in deionized water and ammonia water is added, and the weight concentrations of metal sulfate and ammonia water are respectively 3-12% and 5-10%.

[0102] [2] Add silane coupling agent KH560 into the mixed solution of ethanol and water, add acetic acid dropwise, stir, and hydrolyze at room temperature for half an hour to obtain a silane coupling agent solution, the mass ratio of ethanol: silane coupling agent: water: acetic acid 100:3~10:5~20:1~3;

[0103] [3] The graphene oxide slurry prepared in step [1] was pumpe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com