Monolithic integrated GaN/Ga2O3 Cascode enhanced anti-single event burnout device and preparation method thereof

A monolithic integration and anti-single event technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problems of low devices and low threshold voltage, and achieve the effect of increasing threshold voltage and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

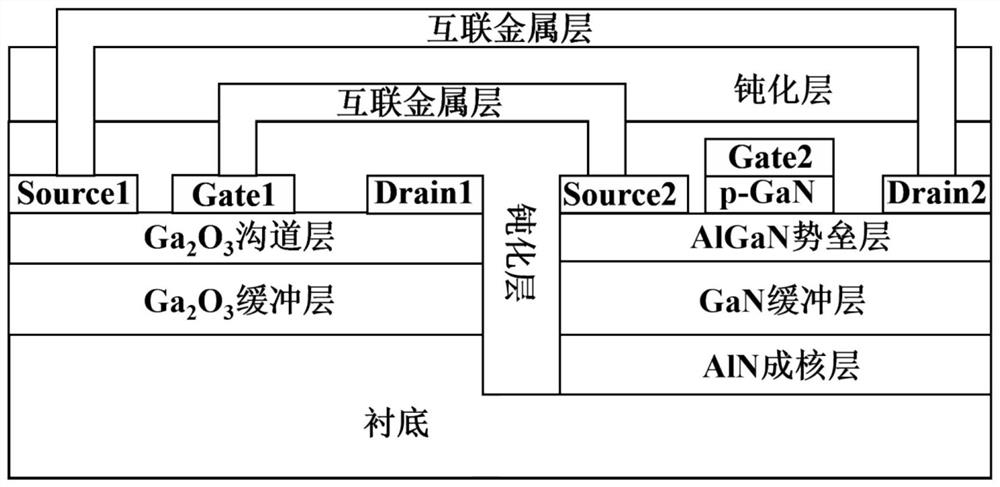

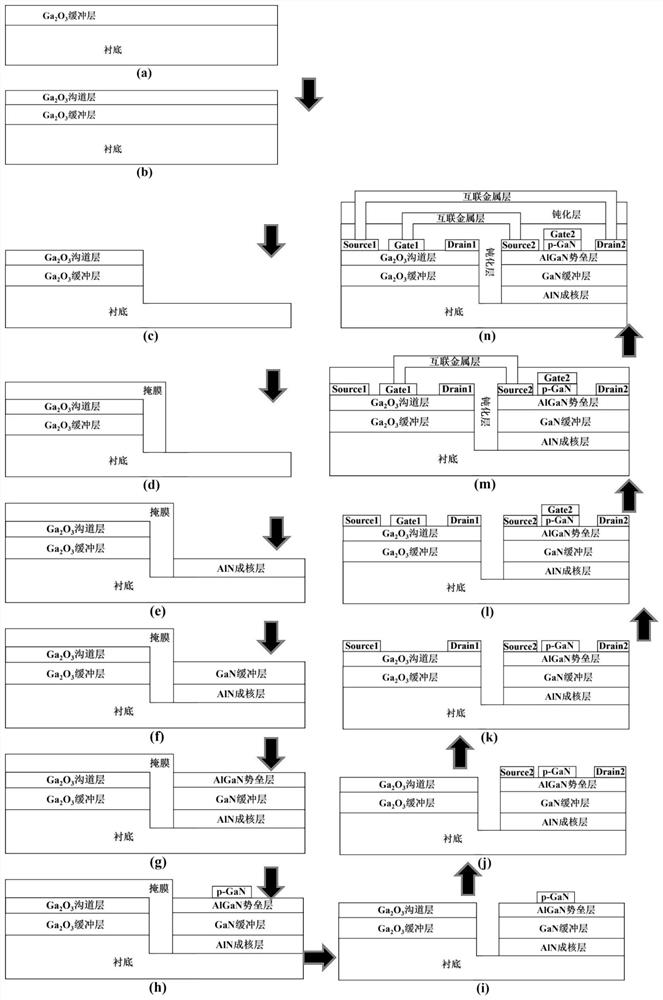

[0041] figure 2 This is the flow chart of the present invention to make a Cascode structure enhanced power device. As shown in the figure, a monolithic integrated GaN / Ga 2 O 3 The preparation method of the Cascode-enhanced anti-single particle burnout device comprises the following steps:

[0042] (1) The substrate surface is cleaned and pretreated to eliminate surface dangling bonds, and in H 2 Heat treatment at a temperature of 900℃-1200℃ in the atmosphere reaction chamber to remove surface contaminants;

[0043] (2) After the heat treatment, the substrate is deposited with a thickness of 100nm-1000nm by MOCVD process. 2 O 3 , as Ga 2 O 3 Buffer layer of FET structure;

[0044] (3) in Ga 2 O 3 On the buffer layer, MOCVD process is used to deposit Ga with a thickness of 100nm-1000nm 2 O 3 , as the channel layer of the device, and the doping concentration is 1 × 10 15 cm -3 -1×10 20 cm -3 Si;

[0045] (4) in Ga 2 O 3 A mask layer is grown on the channel laye...

Embodiment 1

[0061] Made with gallium oxide Ga 2 O 3 is the substrate, and Ga 2 O 3 Monolithically integrated GaN / Ga with 500nm FET channel layer thickness 2 O 3 Cascode Enhanced Anti-Single Event Burnout Device.

[0062] Step 1, to GaO 2 O 3 The substrate surface is pretreated to eliminate dangling bonds.

[0063] 1.1) The gallium oxide Ga 2 O 3 The substrate was soaked in HF acid solution for 1 min, and then placed in acetone solution, absolute ethanol solution and deionized water for ultrasonic cleaning for 10 min each, and the cleaned gallium oxide Ga 2 O 3 The substrate was blown dry with nitrogen;

[0064] 1.2) In H 2 The cleaned and blown-dried substrates are heat treated at a temperature of 1000°C in an atmosphere reaction chamber to remove surface contaminants.

[0065] Step 2, Make Ga 2 O 3 The buffer layer.

[0066] The preprocessed Ga 2 O 3 The substrate was placed in a metal organic chemical vapor deposition MOCVD system, the pressure of the reaction chamber...

Embodiment 2

[0096] Fabricated with sapphire as substrate, and Ga 2 O 3 Monolithically integrated GaN / Ga with 300nm FET channel layer thickness 2 O 3 Cascode Enhanced Anti-Single Event Burnout Device.

[0097] In step 1, the surface of the sapphire substrate is pretreated to eliminate dangling bonds.

[0098] 1.1) Put the sapphire substrate into the HF acid solution and soak it for 1 min, then put it into acetone solution, absolute ethanol solution and deionized water for ultrasonic cleaning for 10 min each, and dry the cleaned sapphire substrate with nitrogen gas;

[0099] 1.2) In H 2 The cleaned and blown-dried substrates are heat treated at a temperature of 1000°C in an atmosphere reaction chamber to remove surface contaminants.

[0100] Step 2, make Ga 2 O 3 The buffer layer.

[0101] Put the pretreated sapphire substrate into the metal organic chemical vapor deposition MOCVD system, set the pressure of the reaction chamber to 30 Torr and the temperature to 900 ° C; at the sam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com