Electrolyte additive, electrolyte and lithium secondary battery

An electrolyte additive and lithium secondary battery technology, which is applied in the field of lithium-ion batteries, can solve the problems that the battery intercalation and delithiation reactions cannot be carried out normally, the chemical stability window is low, and the battery capacity decays, etc., so as to improve high voltage resistance and improve cycle time. performance, the effect of improving high voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

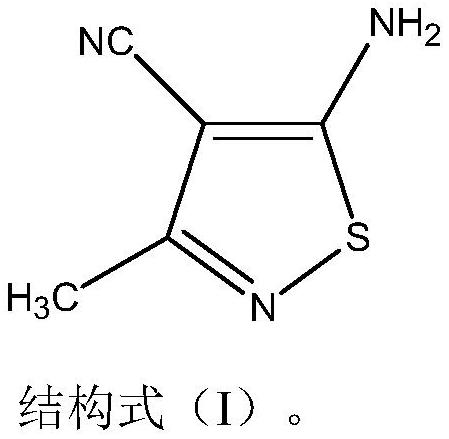

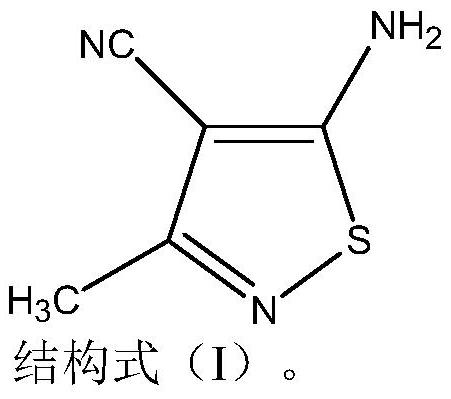

[0023] 1. Preparation of electrolyte: Mix ethylene carbonate (EC), diethyl carbonate (DEC) and ethyl methyl carbonate (EMC) in a mass ratio of EC:DEC:EMC=1:1:1, and after mixing Add 1 mol of lithium hexafluorophosphate (LiPF 6 ), after the lithium salt is completely dissolved, add 0.5% of the additive represented by the structural formula I.

[0024] 2. Preparation of positive electrode sheet: LiNi ternary material LiNi cobalt manganate 0.6 Co 0.2 Mn 0.2 O 2 , Conductive agent SuperP, binder PVDF and carbon nanotubes (CNT) are mixed uniformly in a mass ratio of 97.5:1.5:1:1 to make a certain viscosity of lithium-ion battery cathode slurry, which is coated on the aluminum foil for current collectors. The coating weight is 324g / m 2 , dried at 85°C, and then cold-pressed; then trimmed, cut, and slitted, dried at 85°C for 4 hours under vacuum conditions after slitting, and welded the tabs to make the positive electrode of the lithium-ion battery that meets the requirements. ...

Embodiment 2 4

[0028] The preparation of the electrolyte, the preparation of the positive electrode sheet, the negative electrode sheet and the lithium ion battery are the same as those in Example 1, but the contents of the additives shown in structural formula I are 1.0%, 2.0% and 5.0% respectively.

Embodiment 5

[0030] The preparation of the electrolyte, the preparation of the positive electrode sheet, the negative electrode sheet and the lithium ion battery are the same as those in the first embodiment, but the content of the additive shown in the structural formula I is 0.7%; in addition, this embodiment also adds 0.3% of 1,3- Propane Sultone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com